* Free shipping to North America and most of Europe for orders of $100 or more

ID MBDV Series Low-voltage DC Servo drives Compact Size/Dual-axis design

MBDV Series Low-voltage DC Servo drives is a new generation of universal DC input servo system, the power range is 100W-1500W.● Suitable for 100W-1500W low voltage servo motors

● Compatible with CANopen,Modbus RTU bus control

● Compatible with ABZ incremental encoder and incremental communication encoder

● Compatible with M2DC non-line-saving type 2500 line Incremental/optical encoder

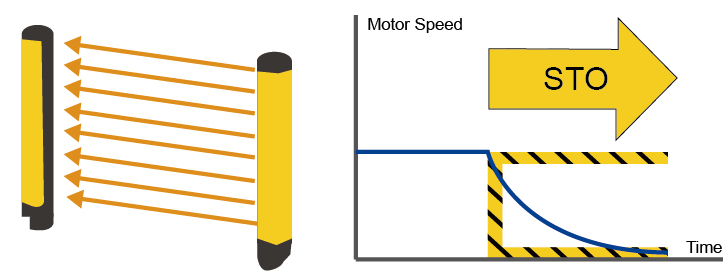

● Support STO function,Meets SIL3(PLe) functional safety level

● AGV special driver

Buyer Protection:

Buyer Protection:

- current tab: Description & Feature

- Data Sheet

- Online Ordering

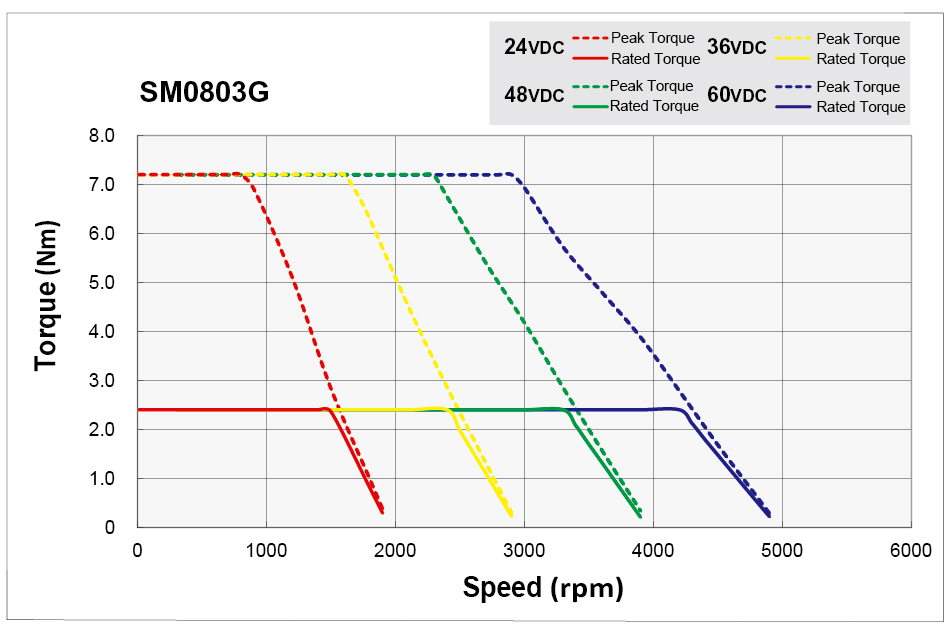

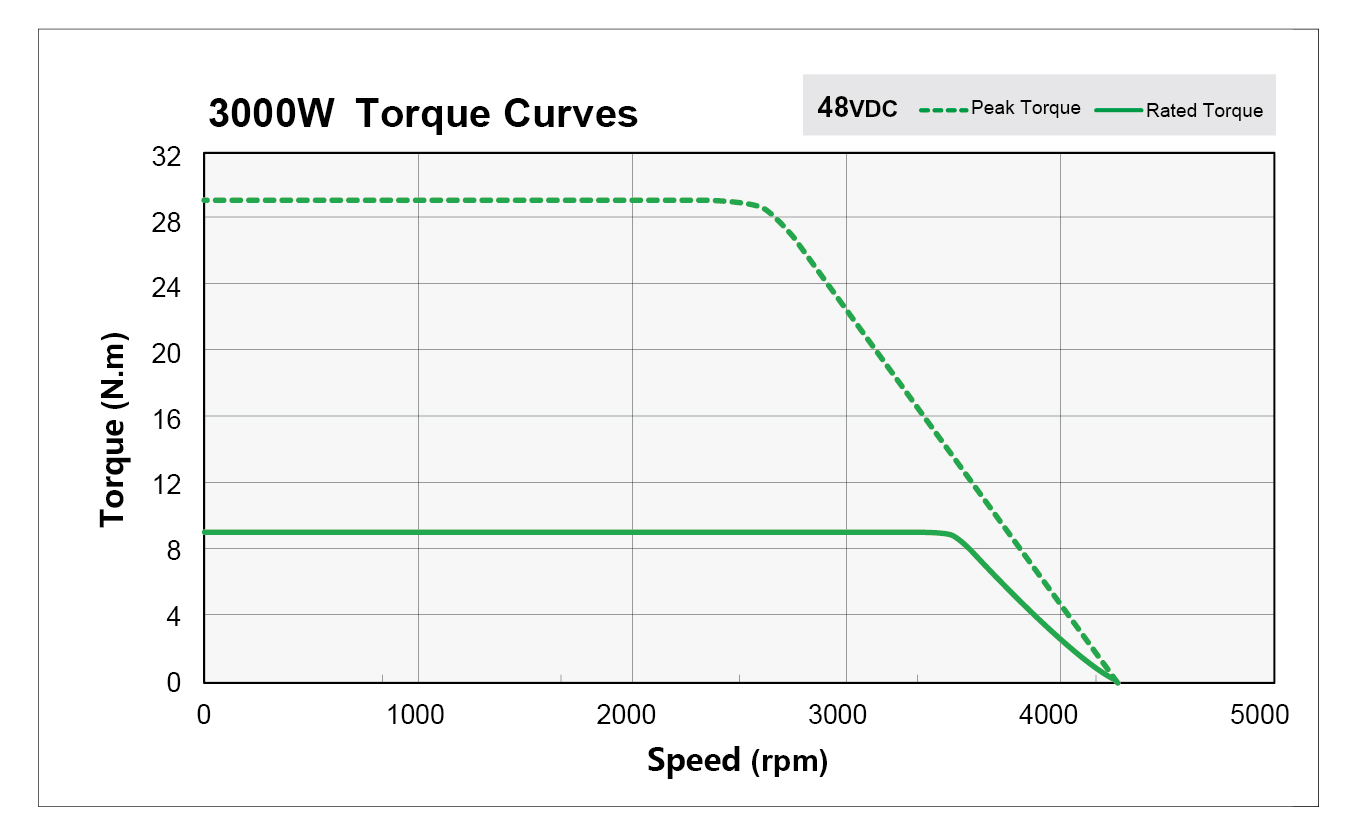

- Torque Speed Curves

- Dimension

- Downloads

- Recommended Options

- User Instructions

- Delivery & Packaging

| Features |

|---|

▪ Robust design for harsh environment applications

▪ Stronger anti vibration ability

▪ Dust, oil and condensation resistance

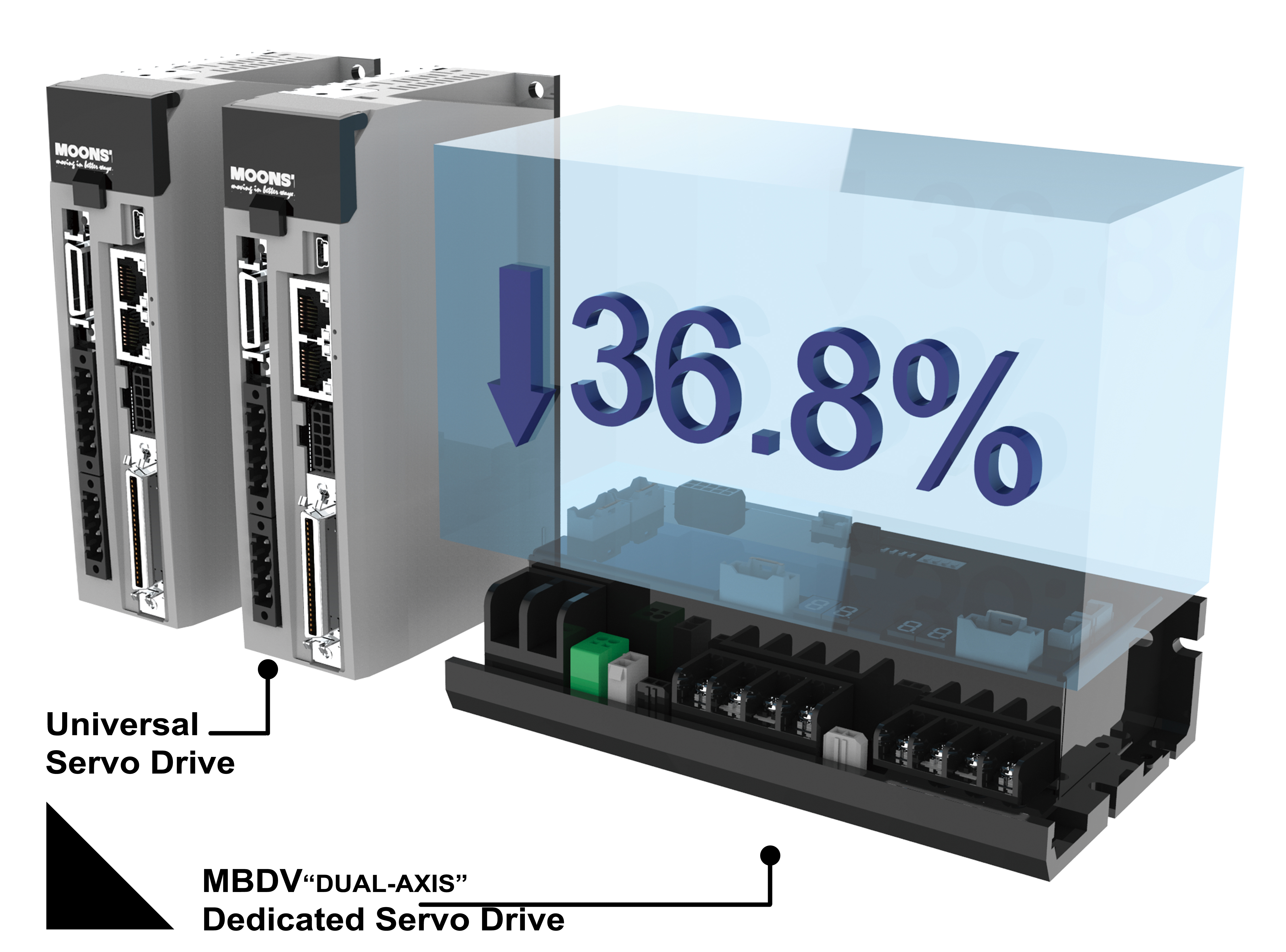

●MBDV 2-in-1 driveMBDV“DUAL-AXIS&rdquodesign significantly reduces the size of the drive, it is a 36.8% drive size reduction compare to conventional servo drives.

●Smaller size and higher efficiency

●New structure and magnetic circuit design ●Shorter length and higher power density

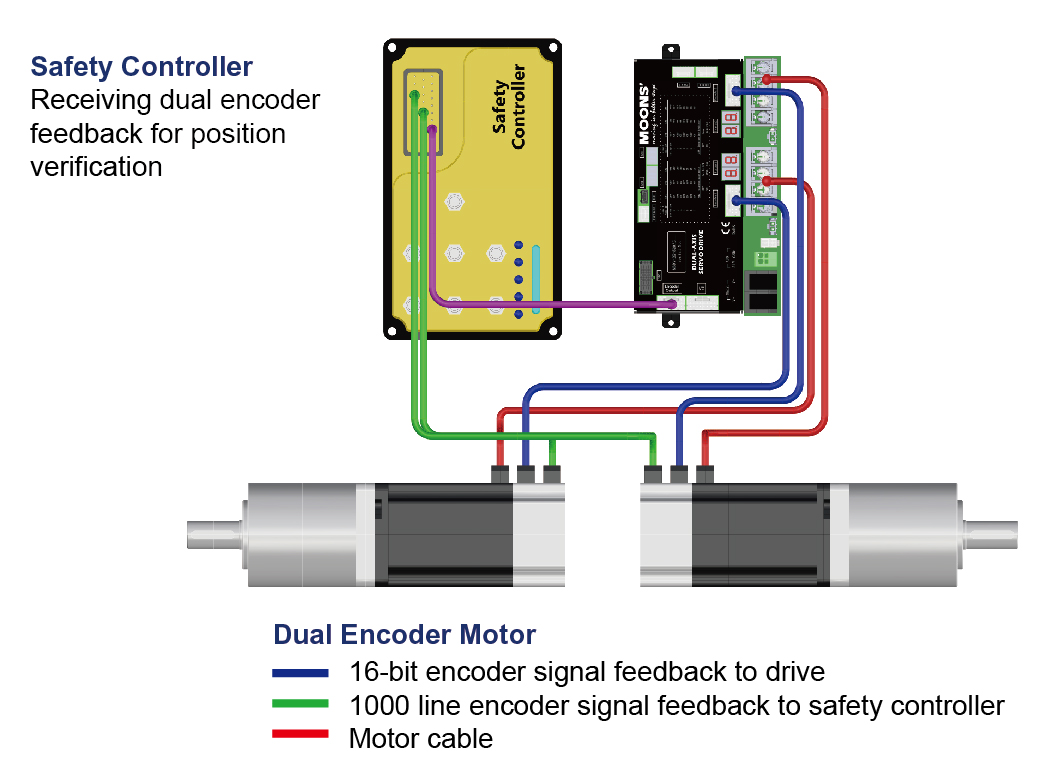

MBDV series drive meets UL61800-5-2(SIL2), IEC61508, ISO138491(PL d).

|  | |

| Without Dynamic brake The drive will switch to disabled after the fault alarm activates. The motor will stay in an uncontrolled deceleration until it stops. The deceleration time depends on factors like speed, inertia, friction etc. | Dynamic brake is in effect The command velocity is set to 0 as soon as the drive is disabled. The actual velocity ramps down immediately as the brake is applied. |

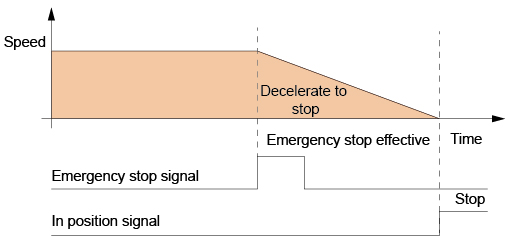

◆ When the motor needs to be decelerated and stopped immediately in an emergency situation during movement, it can be triggered by the I/O or field bus control commands, the motor decelerates according to the set mode.

|  |  |

| Over voltage protection | Over current protection | Over temperature protection |

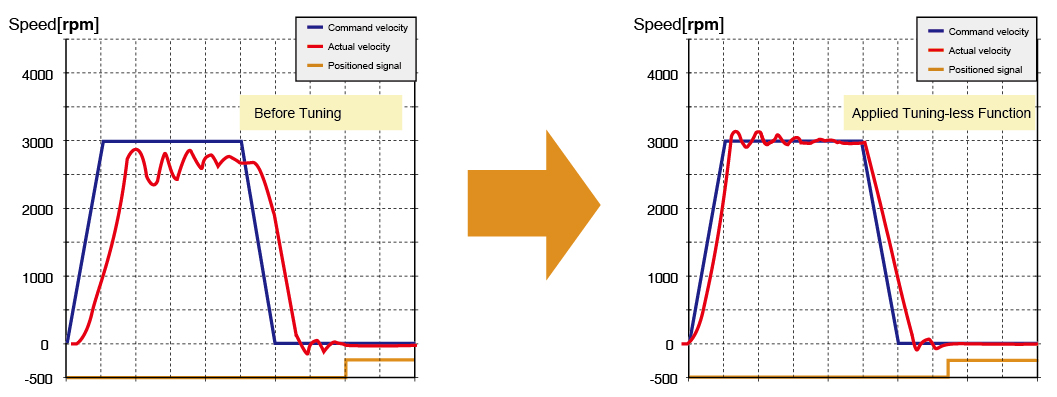

◆ No limitation towards any load type and drive control mode.

◆High robustness for maximum control of servo system stability.

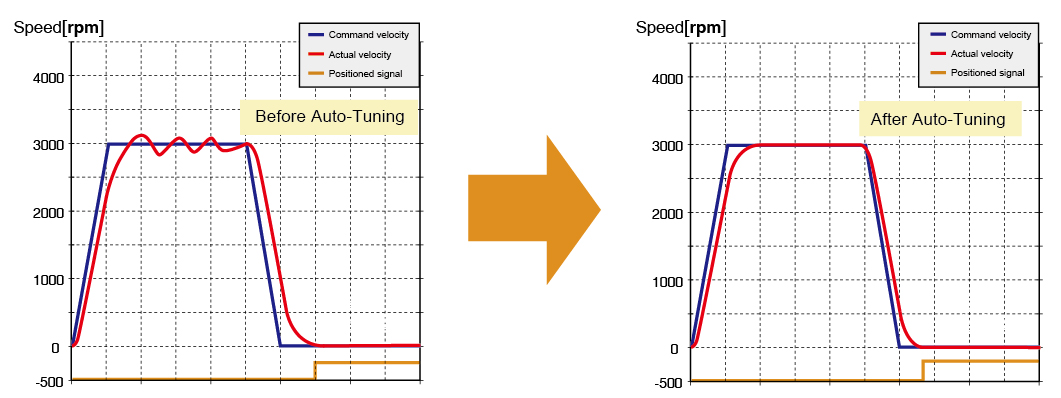

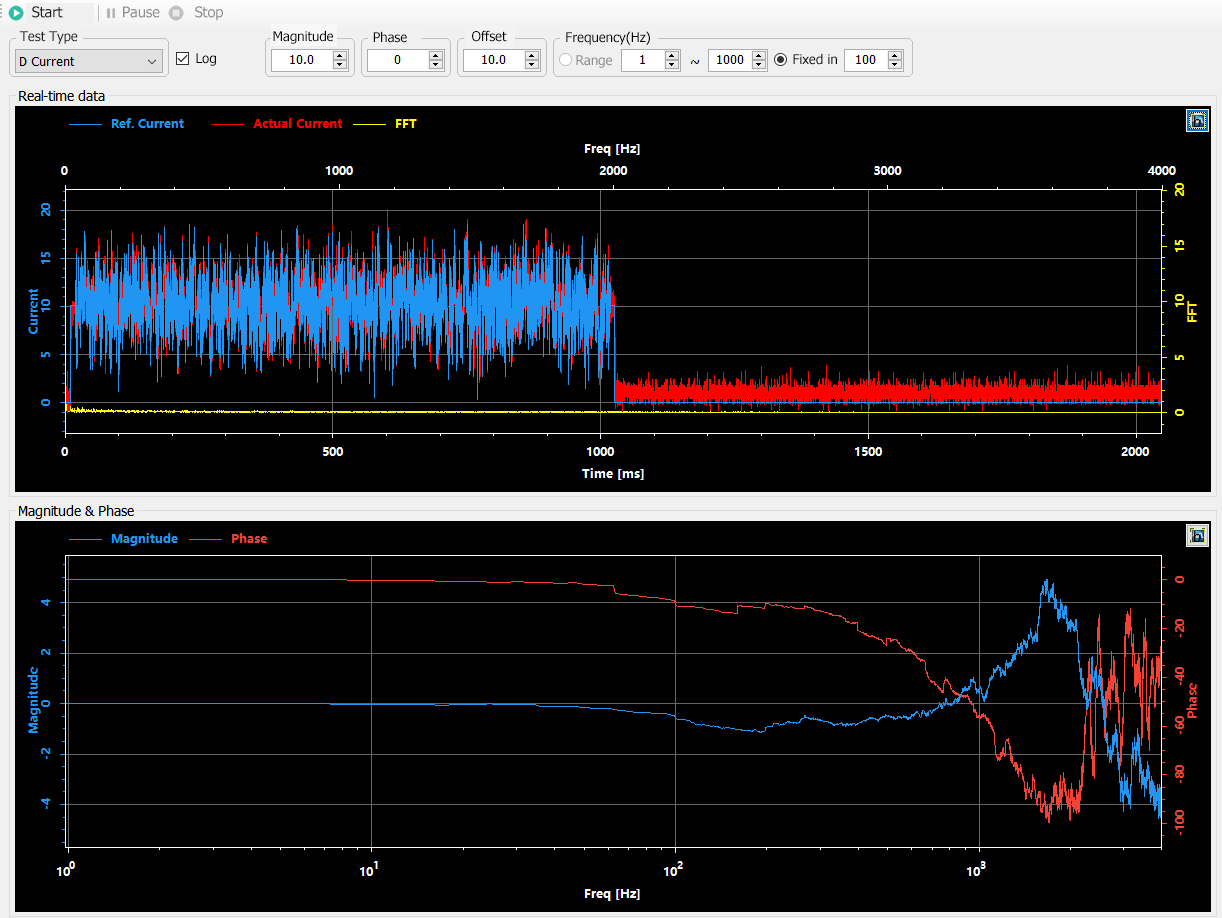

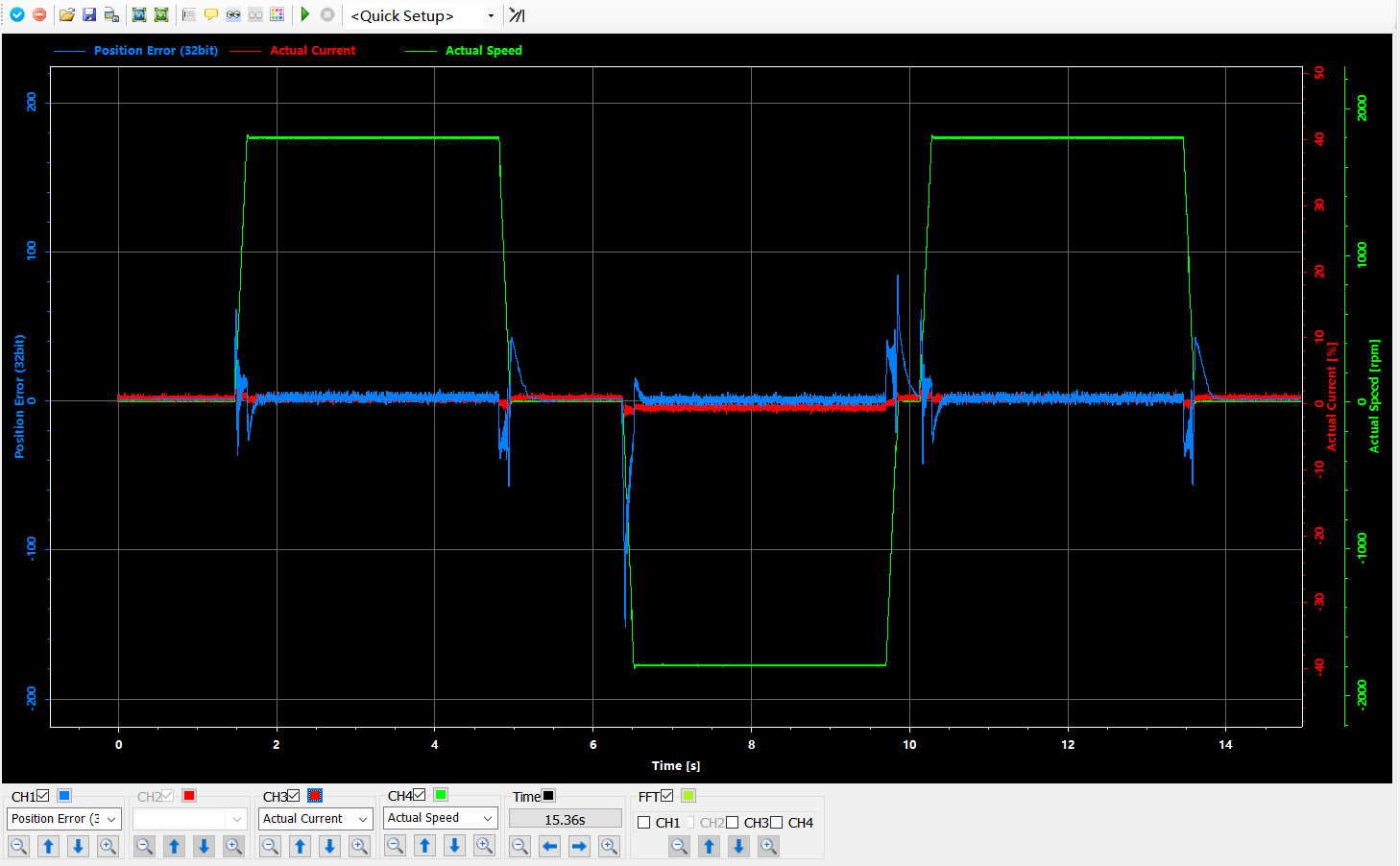

The auto-tuning function can greatly shorten your system tuning time, improve system responsiveness and equipment production efficiency.

| Friendly Sofeware |

|---|

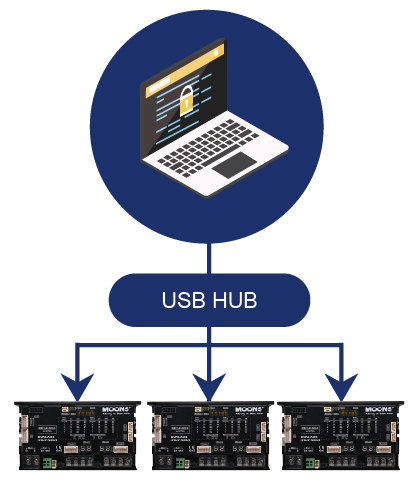

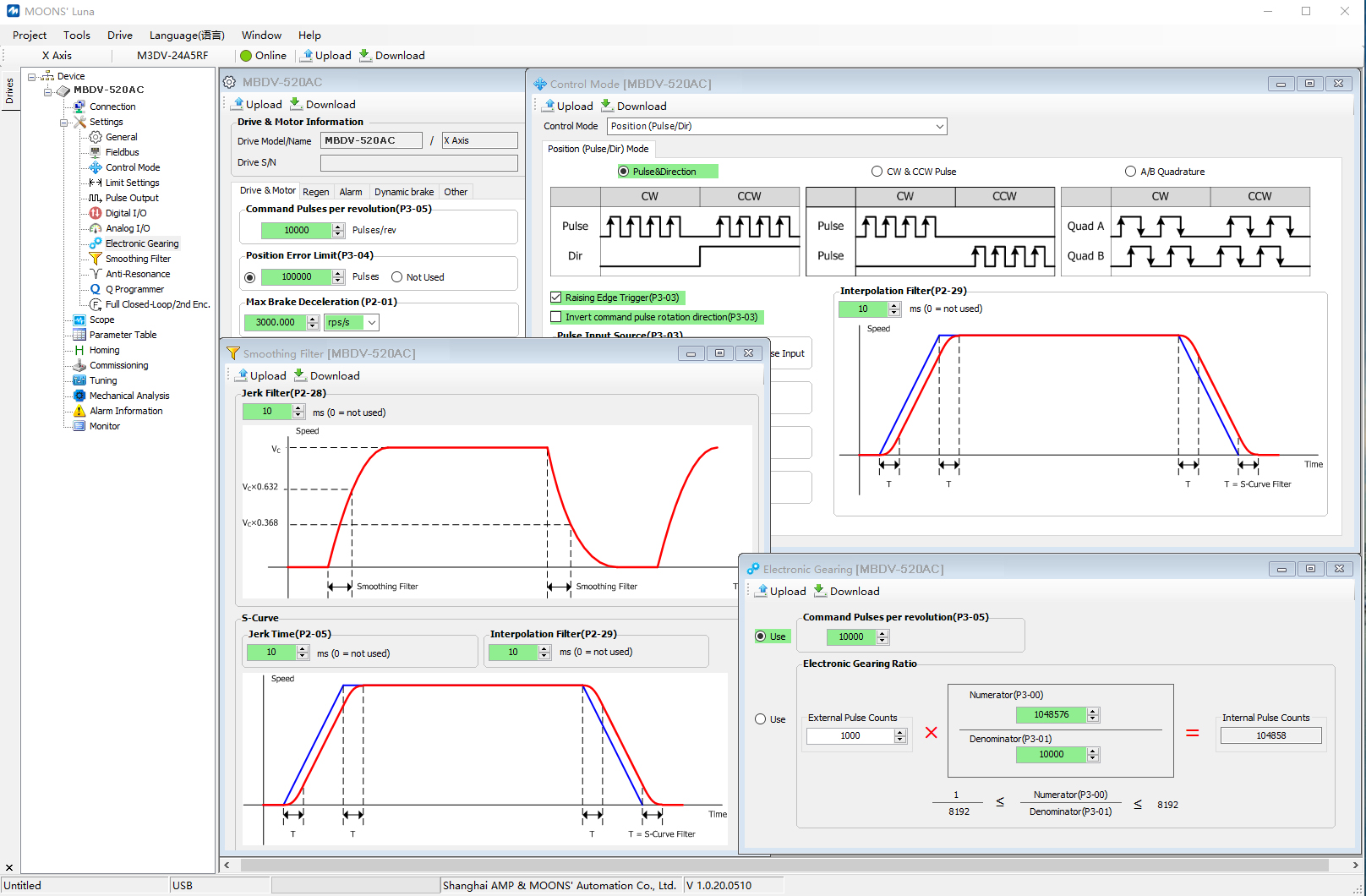

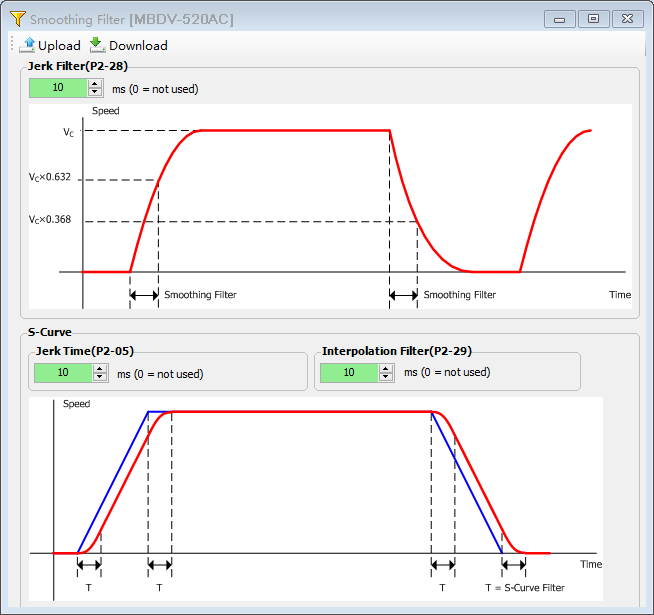

◆ Up to 4 channels with 16bit data per channel and 8kHz sampling rate

◆ Up to 2 channels with 32bit data per channel and 8kHz sampling rate

◆ In the selected cursor area, the software can display the maximum value, minimum value, root mean square, etc.

◆ Customizing trigger conditions

◆ Monitoring the operation status of the drive and the digital inputs and outputs

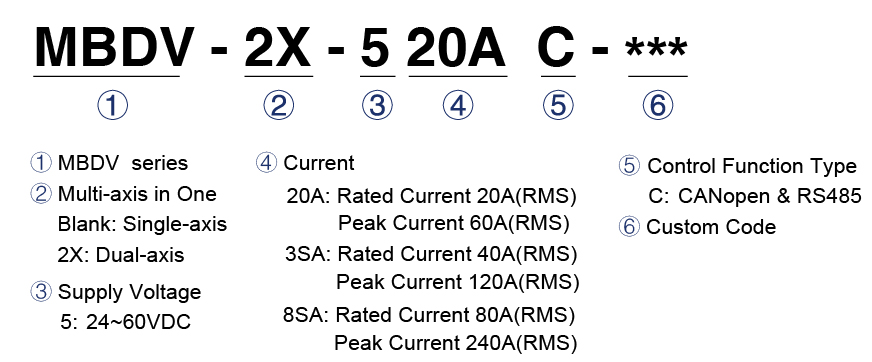

| Numbering System |

|---|

■ MBDV Servo Drive Specification(1)

| Input Power | Main power supply | 24V ~ 60VDC | |

|---|---|---|---|

| Auxiliary power supply | 24VDC±10% | ||

| Withstand Voltage | Primary to earth: withstand 500 VDC, 1 min | ||

| Environment | Temperature | Ambient temperature: 0°C ~ 50°C (If the ambient temperature of servo drive is higher than 45°C, please install the drive in a well-ventilated location) Storage temperature: -20°C ~ 65°C | |

| Humidity | Both operating and storage : 10 ~ 85%RH or less | ||

| Altitude | 1000m and below | ||

| Vibration | 9.8m/s2or less, 10 ~ 60Hz (Do not use continuously at resonance frequency | ||

| Motor Encoder Feedback | 16-bit Incremental magnetic encoder | ||

| I/O*1 | Digital Signal | Input | 4 Configurable optically isolated digital general inputs, 5-24VDC, 20mA |

| Output | 2 Configurable optically isolate digital general outputs, Max.30VDC, 100mA Dedicated motor brake control output, Max.30VDC, 500mA | ||

| Pulse Signal*2 | Output | 3 Line driver output: Encoder A±、B±、Z± | |

| Comm Port | USB mini | Connection with PC for configuration | |

| CANopen | CANopen | ||

| RS-485*3 | Modbus/RTU | ||

| LED Display | 2-digital LED display | ||

| Regeneration Resistor | External resistor is available | ||

| Control Mode | ◆ CANopen CANopen communication control mode Complicate with CiA402 Standard and supports PP, PV, PVT,TQ and HM mode ◆ Modbus/RTU communication control mode Command position mode, command speed mode, command torque mode | ||

| Control Input Signal | Alarm Reset, CW/CCW Limit, Gain Select, Zero Speed Clamp, Emergency Stop, Torque Limit, Speed Limit, General Purpose Input | ||

| Control Output Signal | Warning Output, Fault Output, Servo Ready, Velocity Reached, Torque Reached, Position Reached, Servo-on Status, Brake Release, Dynamic Position Error Following, Positioning Complete, Zero Speed Detected, Velocity Coincidence, Torque Coincidence, Velocity limit, Torque limit, Homing Finished, Soft Limit CW/CCW, General Purpose Output | ||

| Protection | Over Current, Over Voltage, Low Voltage, Low Heating, Bad Encoder Feedback,Over Speed, Position Error, Over Load, Emergency Stop, CW/CCW Limit, Communication Abnormal | ||

| Dynamic Brake | Built in | ||

| STO | Built in | ||

| Certification | RoHS、CE、UL | ||

| Drive Weight | MBDV-520AC:0.3kg MBDV-520AC-F01:0.3kg MBDV-520AC-H01:0.3kg MBDV-53SAC:0.7kg MBDV-2X-520AC:0.6kg MBDV-2X-520AC-F02:0.6kg | ||

*2 Single-axis drive does not support such function, customization is optional

*3 RS485 and CANopen share the common communication interface

■ MBDV Servo Drive Specification(2)

| Input Power | Main power supply | 24V ~ 60VDC | |

|---|---|---|---|

| Auxiliary power supply | 24VDC±10% | ||

| Withstand Voltage | Primary to earth: withstand 500 VDC, 1 min | ||

| Environment | Temperature | Ambient temperature: 0°C ~ 50°C (If the ambient temperature of servo drive is higher than 45°C, please install the drive in a well-ventilated location) Storage temperature: -20°C ~ 65°C | |

| Humidity | Both operating and storage : 10 ~ 85%RH or less | ||

| Altitude | 1000m and below 下 | ||

| Vibration | 9.8m/s2or less, 10 ~ 60Hz (Do not use continuously at resonance frequency) | ||

| Motor Encoder Feedback | 16-bit Incremental magnetic encoder 17-bit Battery-less absolute encoder | ||

| I/O*1 | Digital Signal | Input | 4 Configurable optically isolated digital general inputs, 5-24VDC, 20mA |

| Output | 2 Configurable optically isolate digital general outputs, Max.30VDC, 100mA Dedicated motor brake control output, Max.30VDC, 500mA | ||

| Pulse Signal | Output | 3 Line driver output: Encoder A±、B±、Z± feedback output; | |

| Comm Port | USB mini | Connection with PC for configuration | |

| CANopen | CANopen | ||

| RS-485*2 | Modbus/RTU | ||

| LED Display | 2-digital LED display | ||

| Regeneration Resistor | External resistor is available | ||

| Control Mode | ◆ CANopen communication control mode Complicate with CiA402 Standard and supports PP, PV, PVT,TQ and HM mode ◆ Modbus/RTU communication control mode Command position mode, command speed mode, command torque mode | ||

| Control Input Signal | Alarm Reset, CW/CCW Limit, Gain Select, Zero Speed Clamp, Emergency Stop, Torque Limit, Speed Limit, General Purpose Input | ||

| Control Output Signal | Warning Output, Fault Output, Servo Ready, Velocity Reached, Torque Reached, Position Reached, Servo-on Status, Brake Release, Dynamic Position Error Following, Positioning Complete, Zero Speed Detected, Velocity Coincidence, Torque Coincidence, Velocity limit, Torque limit, Homing Finished, Soft Limit CW/CCW, General Purpose Output | ||

| Protection | Over Current, Over Voltage, Low Voltage, Low Heating, Bad Encoder Feedback,Over Speed, Position Error, Over Load, Emergency Stop, CW/CCW Limit, Communication Abnormal | ||

| Dynamic Brake | Built in | ||

| STO | Built in | ||

| Certification | RoHS、CE、UL | ||

| Drive Weight | MBDV-2X-53SAC:1.4kg MBDV-58SAC:1.5kg | ||

*2 RS485 and CANopen share the common communication interface

■ Certification Specification

| - | - | Drive | Motor |

|---|---|---|---|

| Europe | EMC Command | EN 61800-3 | EN 55011 |

| EN 55014-1 | |||

| EN 55014-2 | |||

| EN 6100-3-2 | |||

| EN 6100-3-3 | |||

| STO | UL61800-5-2(SIL3) | - | |

| IEC61508 | - | ||

| ISO13849-1(PL e) | - | ||

| UL Standard | UL 61800-5-1 | UL 1004-1 | |

| UL 1004-6 | |||

| CSA Standard | C22.2 No.274.13 | CSA C22.2 No.100 | |

■ Motor Specification

| Insulation Class | Class F (155℃ ) | Ambient Temperature | Operating 0 to 50°C, Storage -20 to 60°C |

|---|---|---|---|

| IP65 Rating | IP65 (Except transfixion part of shaft) ) | Ambient Humidity | Operate where the relative humidity range is 20% to 85% and non-condensing |

| Installation Iocation | Indoor installation, avoiding direct sunlight, corrosive and flammable gas | Altitude | Operating 1,000m |

| Vibration | Under 49m/s2, 10 ~ 60Hz(Do not use continuously at resonance frequency ) | - | - |

■ Brake Specification

When the brake is powered on, the armature is adsorbed, the brake pad is released, and the motor can operate normally.

When the brake is powered off, the armature is released, the brake pad is locked, and the motor can't rotate normally.

| Frame Size | 40mm | 60mm | 80mm | 100mm | 110mm | 130mm |  |

|---|---|---|---|---|---|---|---|

| Static friction torque (Nm) | 0.32 | 1.5 | 3.2 | 7 | 8 | 15 | |

| Rated Voltage (VDC) | 24 | ||||||

| Power (W)(20℃) | 6.9 | 7.2 | 10 | 16 | 19.5 | 19.5 | |

| Rated Current (A) | 0.26 | 0.3 | 0.42 | 0.67 | 0.8 | 0.8 | |

| Brake Time | < 70ms (Standard air gap, at 20℃) | ||||||

| Release Time | <25ms | ||||||

| Release Voltage | 18.5VDC max.(at 20℃) | ||||||

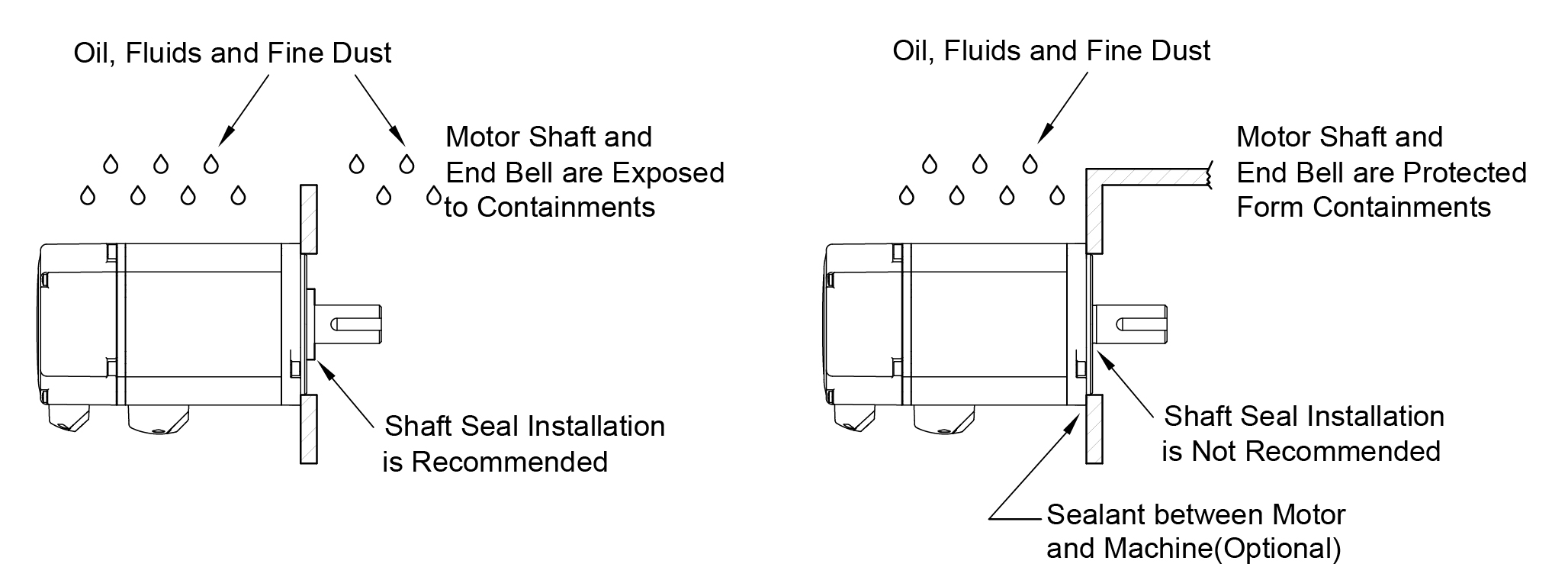

■ Shaft Seal

| Compare | Item | Price (USD) |

|---|---|---|

|

|

MBDV-520AC | |

|

|

MBDV-520AC-F01 | |

|

|

MBDV-520AC-H01 | |

|

|

MBDV-2X-520AC | |

|

|

MBDV-2X-520AC-F02 | |

|

|

MBDV-53SAC | |

|

|

MBDV-2X-53SAC | |

|

|

MBDV-58SAC |

■ Single Encoder Servo Motor —Frame 40mm/60mm/80mm

■ Dual Encoder Servo Motor—Frame 60mm/80mm

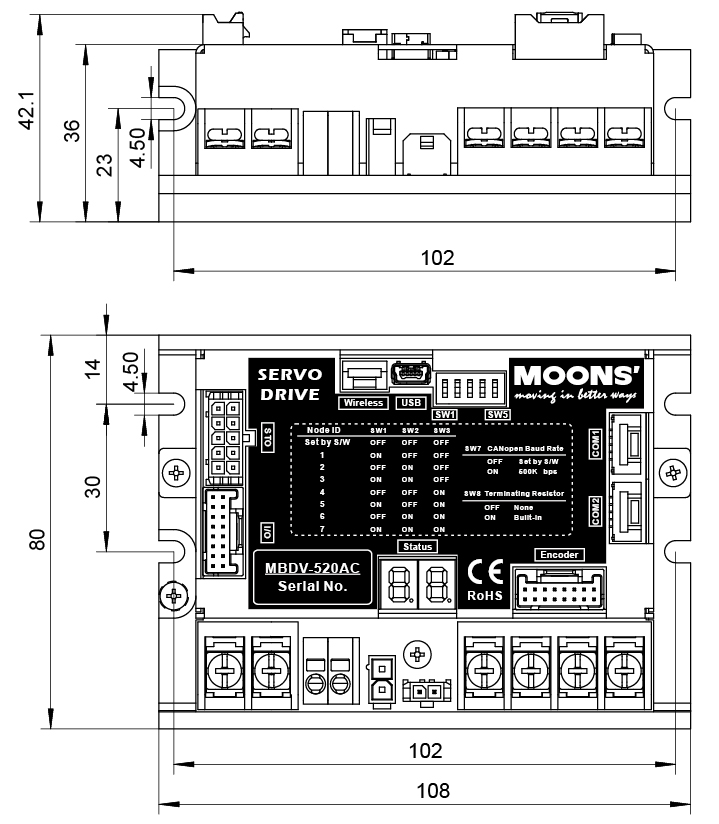

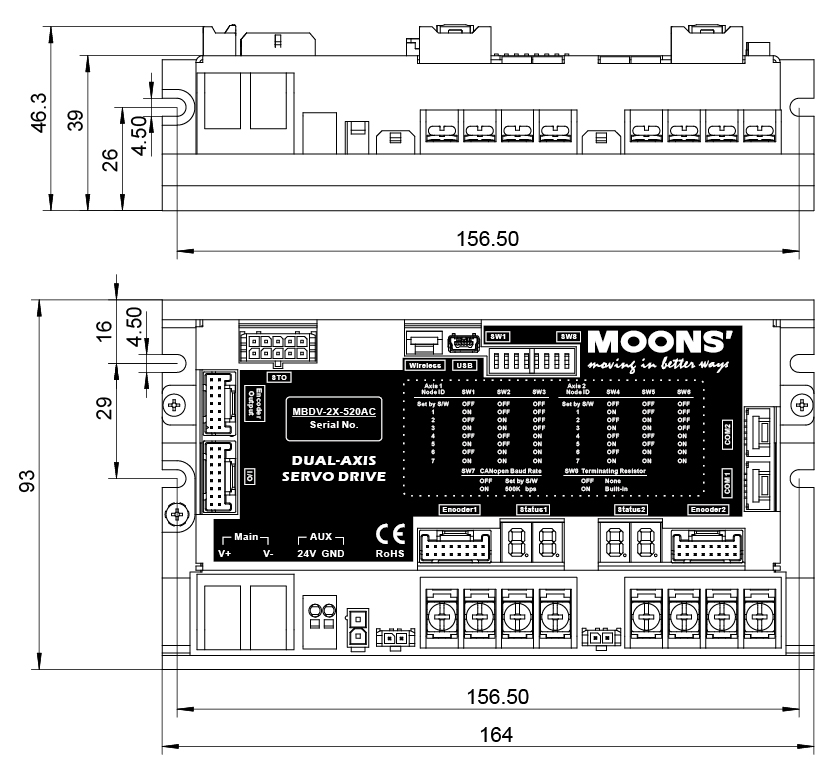

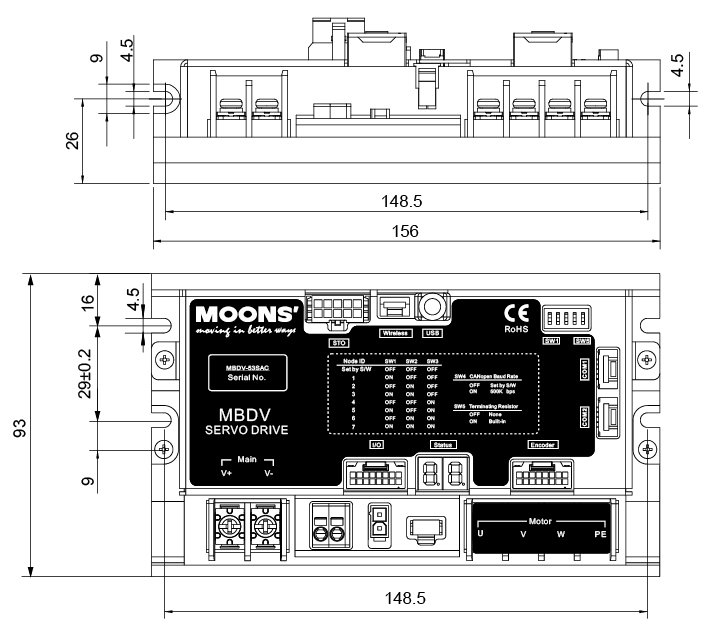

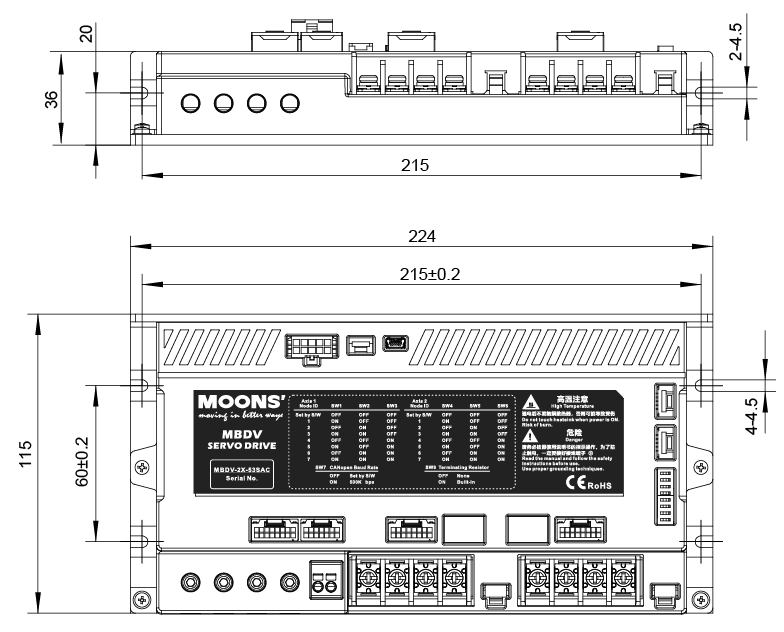

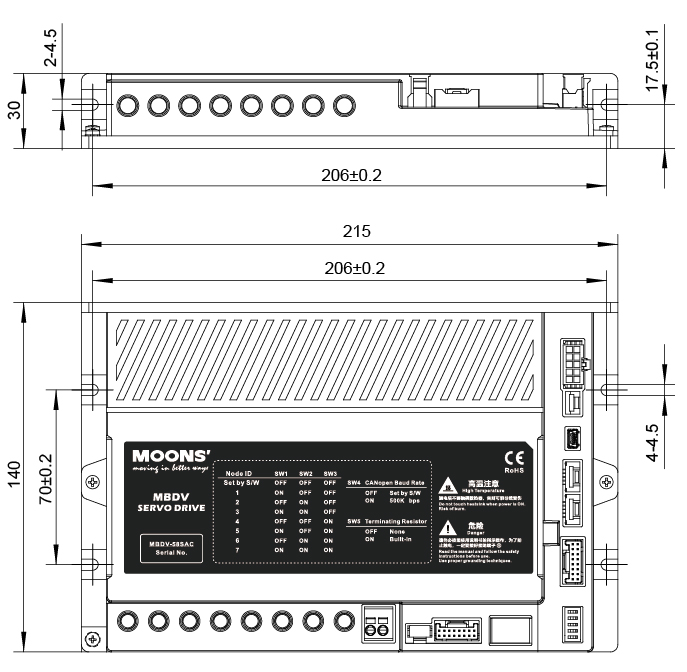

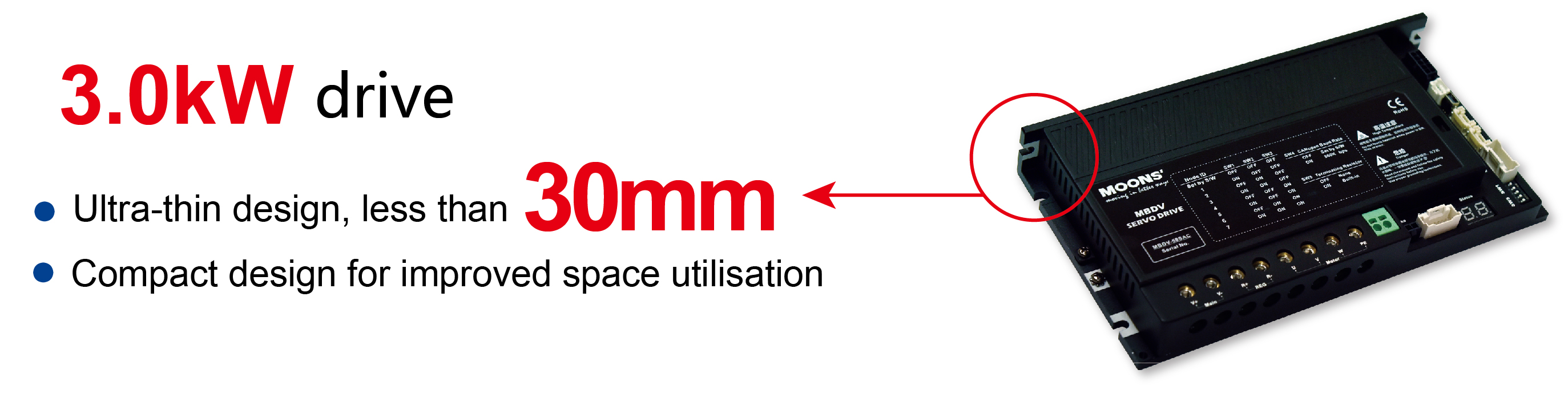

■ Drive(Unit:mm)

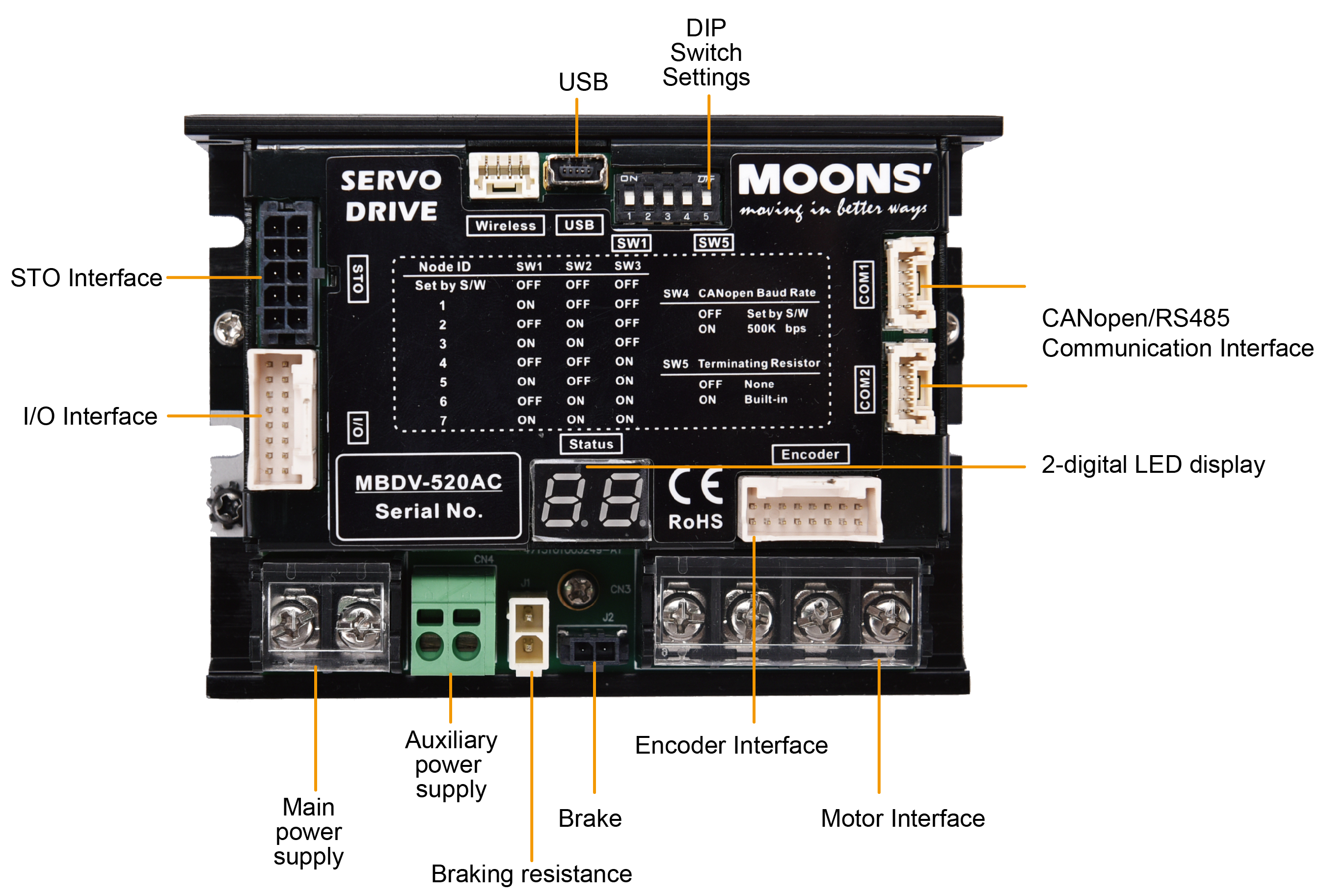

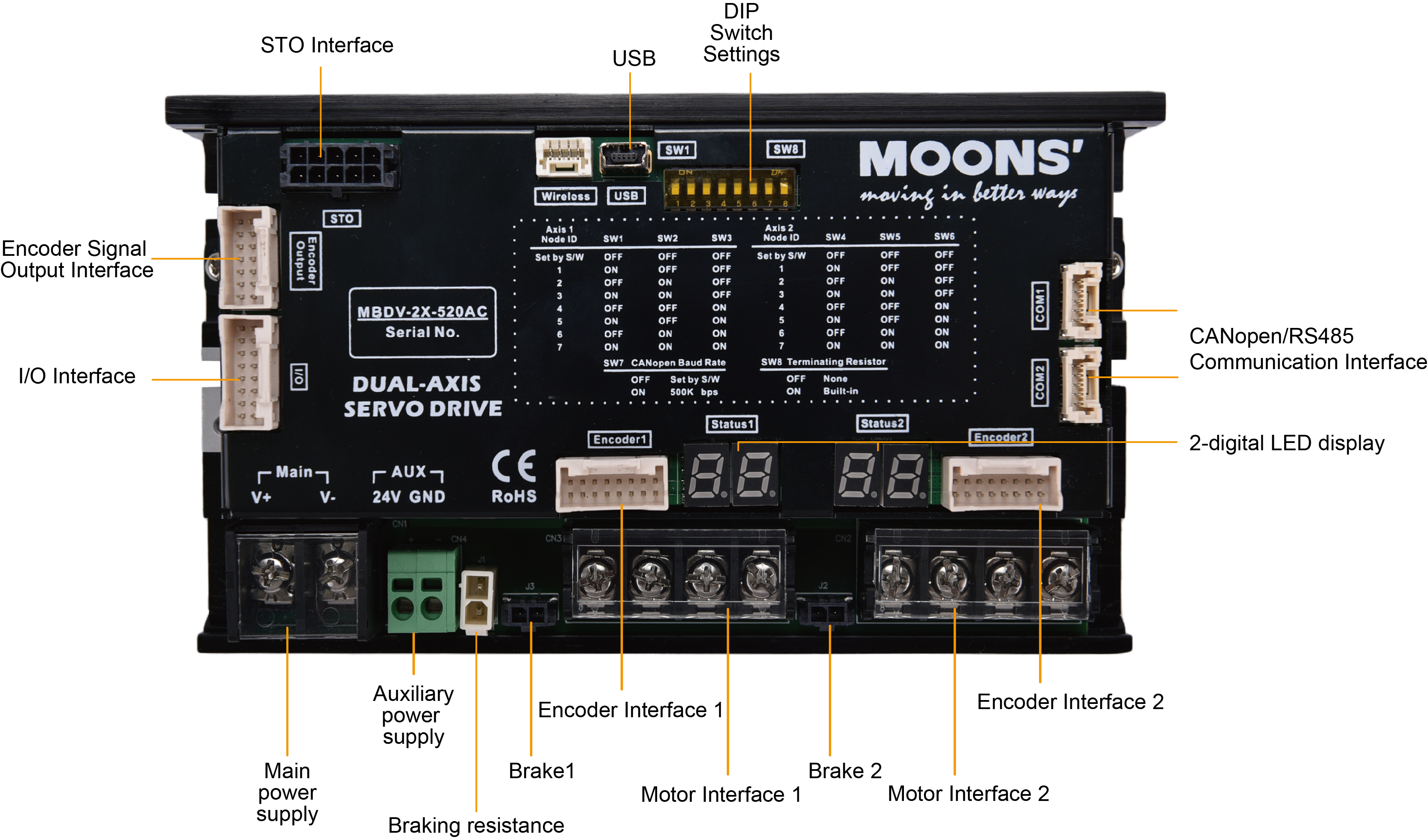

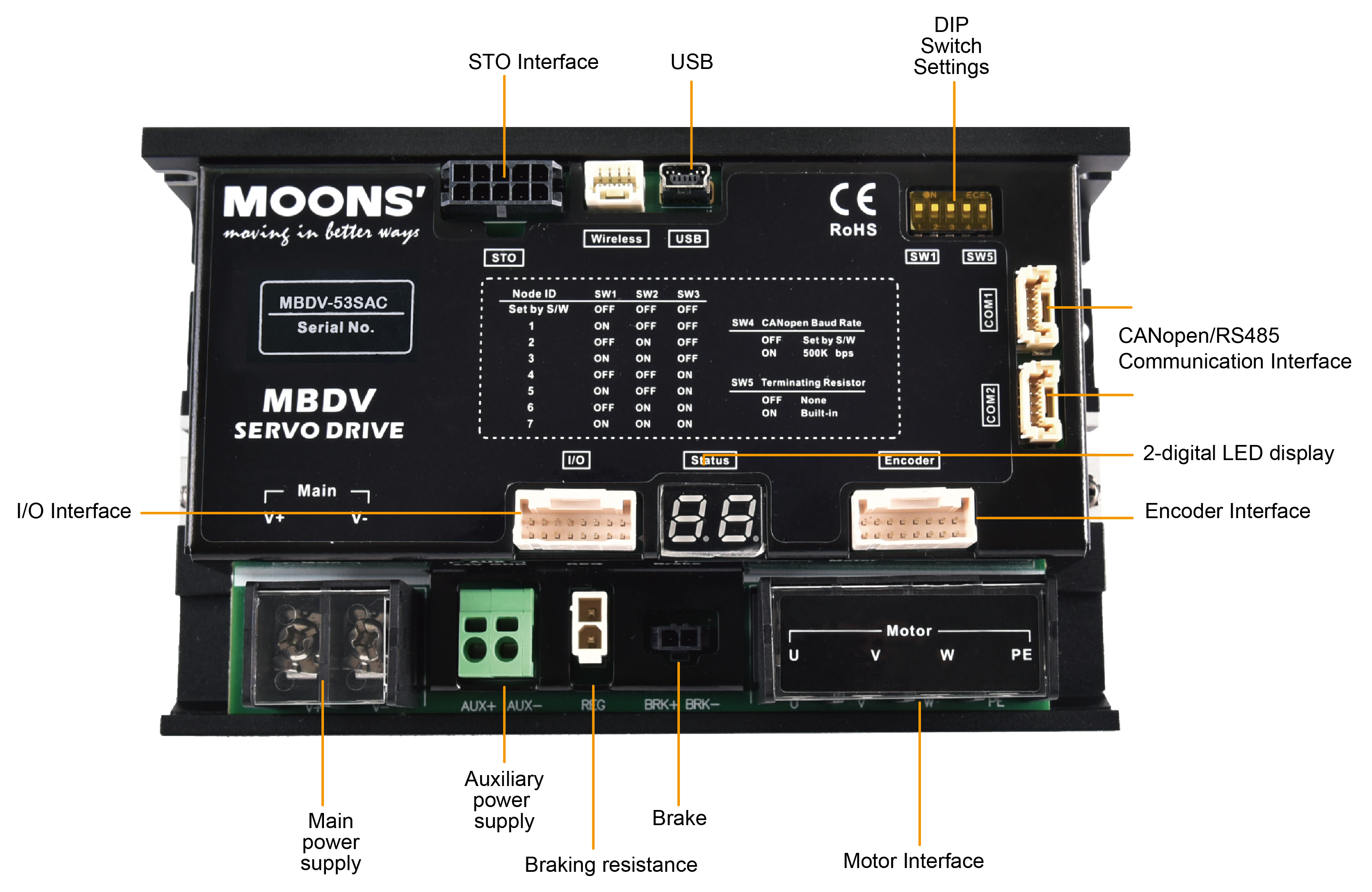

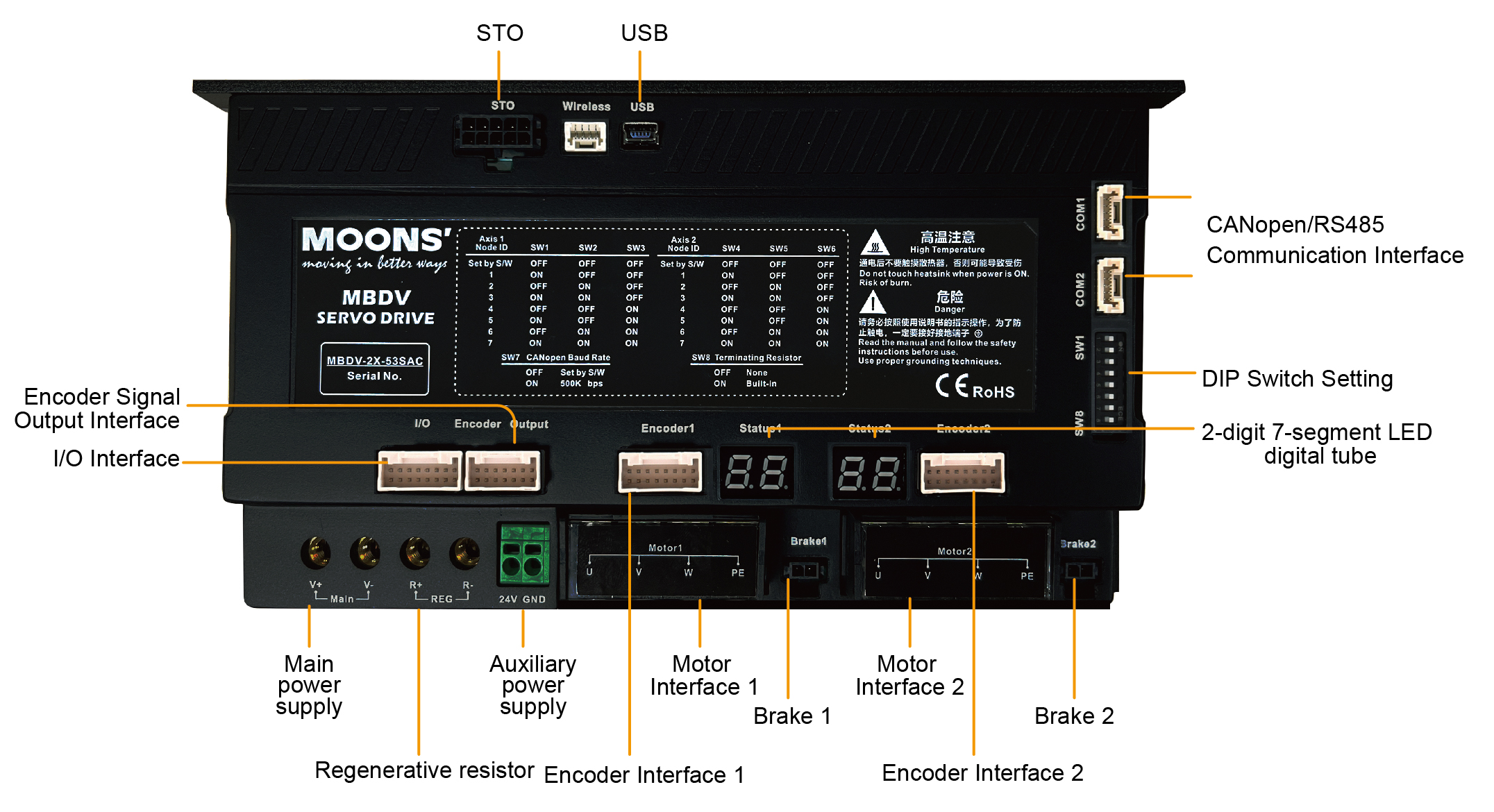

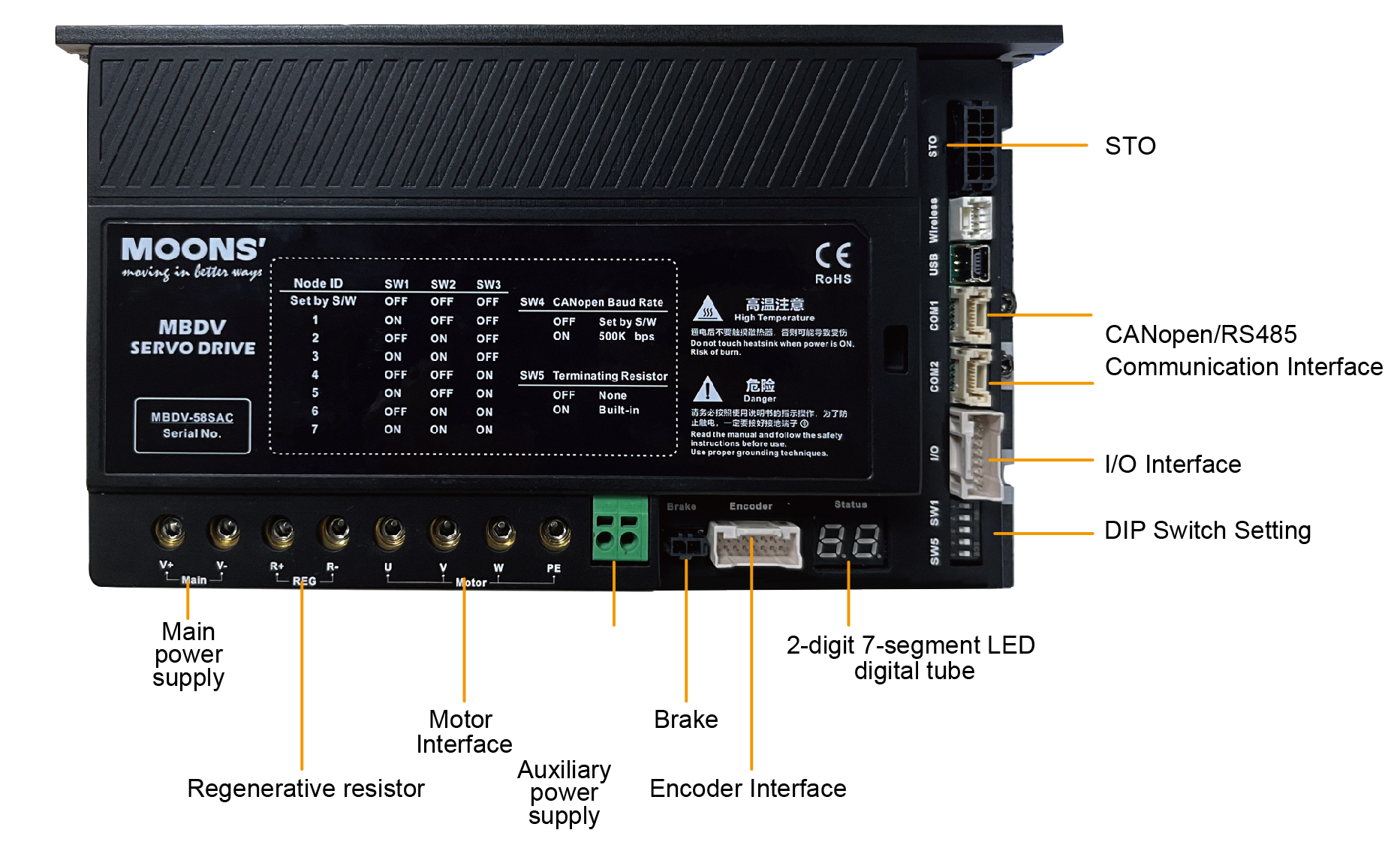

■ Drive Interface Description

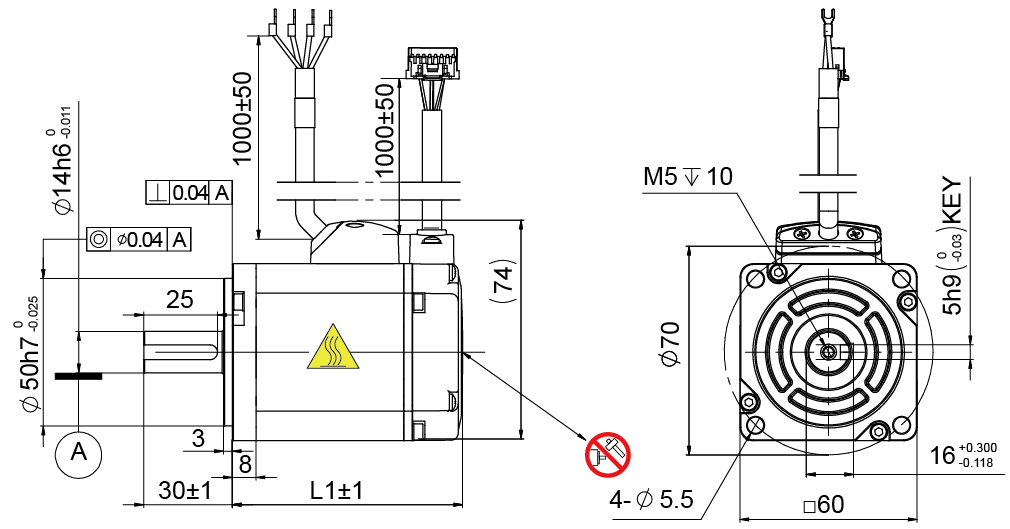

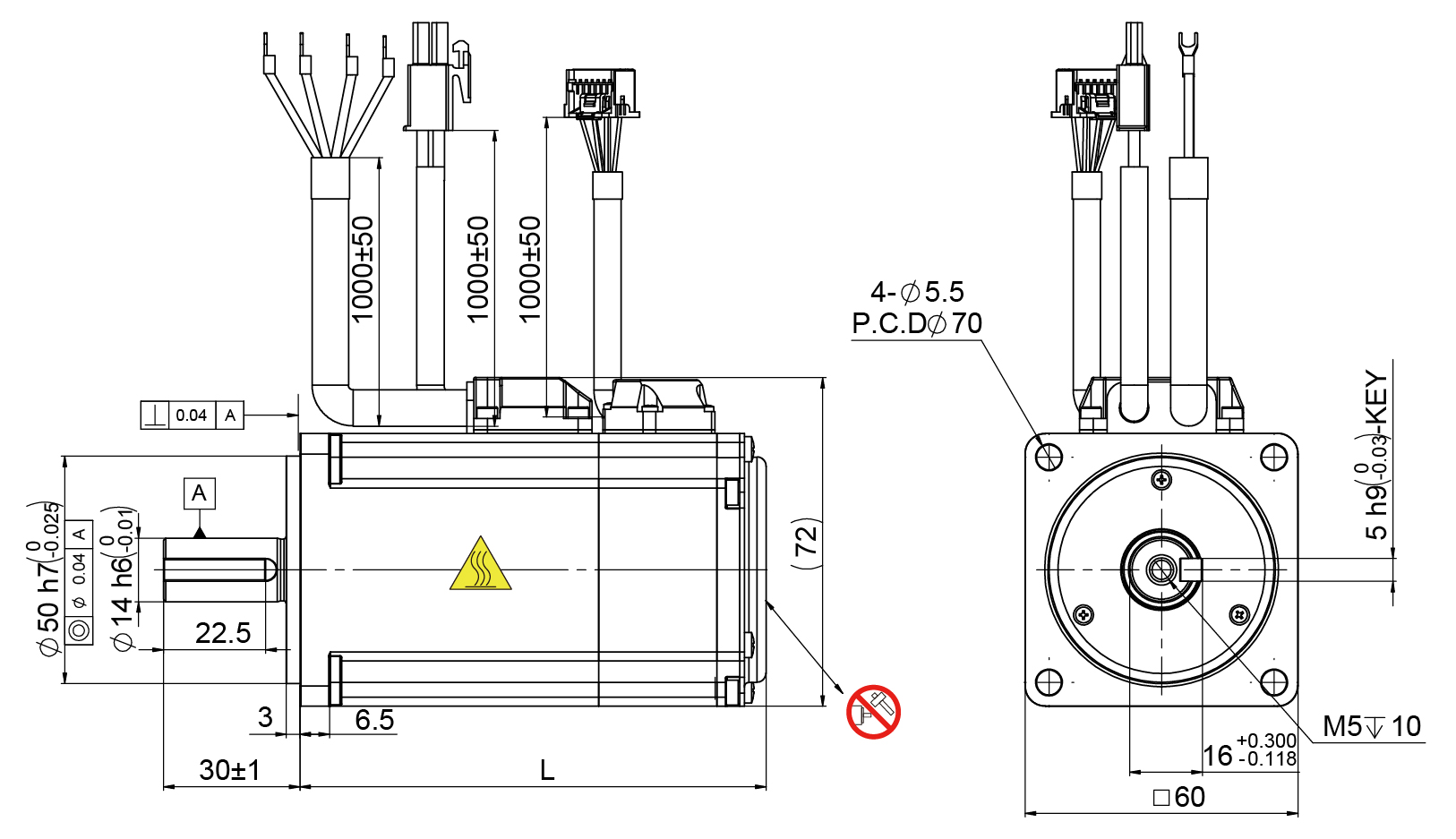

■Servo Motor Mechanical Dimensions(Unit:mm)

□ Frame 40mm — Singal Encoder

| Model | L1 |

|---|---|

| SM0402JSL-KCY-NNV | 96 |

| SM0402GSL-KCY-NNV | 96 |

| Model | L1 |

|---|---|

| SM0402JSL-KCY-BNV | 133 |

| SM0402GSL-KCY-BNV | 133 |

□ Frame 60mm — Singal Encoder

| Model | L1 |

|---|---|

| SM0601JSL-KCY-NNV | 78 |

| SM0601GSL-KCY-NNV | 78 |

| SM0602GSL-KCY-NNV | 107 |

| Model | L1 |

|---|---|

| SM0601JSL-KCY-BNV | 117.5 |

| SM0601GSL-KCY-BNV | 117.5 |

| SM0602GSL-KCY-BNV | 146.5 |

□ Slim Servo Motor——Frame 60mm, Single EncoderNEW

| Model | L |

|---|---|

| SM0602GSL-KCY-NNN | 76.5 |

| Model | L |

|---|---|

| SM0602GSL-KCY-BNN | 102.5 |

□ Slim Servo Motor——Frame 80mm, Single EncoderNEW

| Model | L |

|---|---|

| SM0803GSL-KCY-NNN-10 | 78.5 |

| Model | L |

|---|---|

| SM0803GSL-KCY-BNN-10 | 110.5 |

□ Frame 80mm — Singal Encoder

| Model | L1 |

|---|---|

| SM0803GSL-KCY-NNV | 110 |

| SM0804GSL-KCY-NNV | 124.7 |

| Model | L1 |

|---|---|

| SM0803GSL-KCY-BNV | 156.8 |

| SM0804GSL-KCY-BNV | 171.3 |

□ Frame 60mm — Dual Encoder

| Model | L1 |

|---|---|

| SM0601JEL-KCY-NNV | 98 |

| SM0601GEL-KCY-NNV | 98 |

| SM0602GEL-KCY-NNV | 127 |

| Model | L1 |

|---|---|

| SM0601JEL-KCY-BNV | 137.5 |

| SM0601GEL-KCY-BNV | 137.5 |

| SM0602GEL-KCY-BNV | 166.5 |

□ Frame 80mm — Dual Encoder

| Model | L1 |

|---|---|

| SM0803GEL-KCY-NNV | 130.8 |

| Model | L1 |

|---|---|

| SM0803GEL-KCY-BNV | 178.8 |

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| MBDV-520AC.pdf | 305 | ||

| MBDV-2X-520AC.pdf | 309 | ||

| MBDV-2X-520AC-F02.pdf | 309 | ||

| MBDV-53SAC.pdf | 280 | ||

| MBDV-58SAC.pdf | 248 | ||

| MBDV-520AC-F01.pdf | 408 | ||

| MBDV-520AC-H01.pdf | 408 | ||

| MBDV-2X-53SAC.pdf | 345 |

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| MBDV-53SAC.STP | STEP | 13748 | |

| MBDV-2X-520AC.STEP | STEP | 26152 | |

| MBDV-520AC.STEP | STEP | 25580 | |

| MBDV-2X-520AC-F02.STEP | STEP | 26152 | |

| MBDV-520AC-H01.STEP | STEP | 25580 | |

| MBDV-58SAC.stp | STEP | 8352 | |

| MBDV-2X-53SAC.stp | STEP | 13597 | |

| MBDV-520AC-F01.STEP | STEP | 25580 |

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| MBDV Family Brochure_EN20241218.pdf | 6409 |

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| MBDV Hardware Manual_EN.pdf | 5477 |

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| Low Voltage Family Brochure_EN.pdf | 6141 |

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| ROHS declaration-2025-A0.pdf | 507 | ||

| UL-CA-2329355-0-MBDV-UL.pdf | 236 | ||

| CE Certification for MBDV .pdf | 1029 |

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| Luna Setup 4.0.25.0428.zip | ZIP | 31132 | |

| CANOPEN-EDS-MBDV-Servo-DulAxes-V1.0.eds | EDS | 59 | |

| CANOPEN-EDS-MBDV-Servo-SingleAxis-V1.1.eds | EDS | 72 |

Filter By Product Type

All ProductsExtended I/O Cables

USB Configuration Cable

Encoder Output Signal Cable

Communiaction Cable

Motor Types

Regen Clamp

RS485 Adapter

Driving Wheel

■Accessories

| USB Cable |

|---|

| Model | LengthL(mm) | Description | Outline |

|---|---|---|---|

| 2620-150 | 1.5m | USB configuration cable connect with PC and servo drive |

| Communication Cable |

|---|

| Model | LengthL(mm) | Description | Outline |

|---|---|---|---|

| 2111-025 | 0.25m | CANopen/RS485 communication cable | |

| 2111-050 | 0.5m | ||

| 2111-100 | 1m | ||

| 2111-300 | 3m |

| I/O signal cable |

|---|

| Model | LengthL(mm) | Description | Outline |

|---|---|---|---|

| 1653-050 | 0.5m | 16Pin I/O signal cable | |

| 1653-100 | 1m | ||

| 1653-200 | 2m |

| Encoder Output Signal Cable ( For MBDV-2X-520AC, MBDV-2X-520AC-F02 and MBDV-2X-53SAC Series) |

|---|

| Model | LengthL(mm) | Description | Outline |

|---|---|---|---|

| 1108-100 | 1m | 14Pin encoder output signal cable | |

| 1108-200 | 2m |

■Connector Kit

| Motor Encoder, Brake Connector(Optional parts, type MBDV Motor Connector Kit) |

|---|

| ◇ Includes |

|---|

| Item | Model | Num. | Manufacturer | Description |

|---|---|---|---|---|

| Connector | 501646-1600 | 1 | Molex | For motor encoder cable |

| Connector PIN | 501648-1000 | 16 | Molex | For motor encoder cable |

| Connector | 43645-0200 | 1 | Molex | For motor brake cable |

| Connector PIN | 43030-0001 | 2 | Molex | For motor brake cable |

| STO Connector( Standard parts, type STO Connector Kit) |

|---|

| ◇ Includes |

|---|

| Item | Model | Num. | Manufacturer | Description |

|---|---|---|---|---|

| Connector | 43025-1000 | 1 | Molex | STO Connector Plastic shell |

| Connector PIN | 43030-0005 | 10 | Molex | STO connector terminals |

| Regenerative Resistor Connector Kit (Optional parts, type MBDV Regen Connector Kit) |

|---|

| ◇ Includes |

|---|

| Item | Model | Num. | Manufacturer | Description |

|---|---|---|---|---|

| Connector | 1586019-2 | 1 | TE | Regenerative energy absorption resistor connector Plastic shell |

| Connector PIN | 2825209-1 | 2 | TE | Regenerative energy absorption resistor connector terminals |

| I/O Connector (Standard parts) |

|---|

| Item | Model | Num. | Manufacturer | Description |

|---|---|---|---|---|

| Connector | 501646-1600 | 1 | Molex | I/O connector Plastic shell |

| Connector PIN | 501648-1000 | 16 | Molex | I/O connector terminals |

| Communication Connertor (Standard parts) |

|---|

| Item | Model | Num. | Manufacturer | Description |

|---|---|---|---|---|

| Connector | ZER-05V-S | 1 | JST | Communication interface connector Plastic shell |

| Connector PIN | SZE-002T-P0.3 | 5 | JST | Communication interface connector terminals |

| Encoder Output Connector (Standard parts, For MBDV-2X-520AC and MBDV-2X-53SAC) |

|---|

| Item | Model | Num. | Manufacturer | Description |

|---|---|---|---|---|

| Connector | 501646-1400 | 1 | Molex | Encoder frequency division output connector Plastic shel |

| Connector PIN | 501648-1000 | 14 | Molex | Encoder frequency division output connector terminals |

Delivery & Packaging

Ensure your ordered products are always safely packaged from easy click to fast delivery to your handsProfessional Product Label

Considering all possible harsh application environments, MOONS' specially designed labels for each product, which pass water-resistance test, durability rub test, high temperature resistance and corrosion resistance tests.Besides, our product labels are attached with QR code linking to product details, which is convenient for clients to view the detail product page with their mobile phones.

Note: This label design is suitable for products of stepper motor.

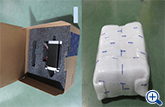

(Professional packing box and unique appearance design)

(Single item packed with EPE)

(Multi-products packed with another box)

Safely Packaging

In order to ensure your shipments withstand the long trip and arrive safely and intact, MOONS' specially designed Individual package to pass the drop test with its stable structure.Besides,the package is made from recyclable materials, providing you with professional safety delivery.

Whether just single item or multi-products the clients buy, all products are packed twice to avoid the damage further.

Shipping Visualization

For each case, products are carefully packed by experienced warehouse staff and the key processes are recorded by photos, which are then posted on our website, so that clients could clearly know the packing process and logistics status after placing order.

(Product in the box)

(Add the invoice)

(Label the commodity)

(The logistics waybill attached)

Fast Delivery

Fast Cross-Border DeliveryMOONS' chooses DHL as our main international express shipping partner. As the world's leading logistics specialist, DHL provides our customers with fast and professional inter- national door-to-door delivery service.

Estimated Delivery Time: e.g. China-USA major cities 3 business days.

Professional

Warehouse Management

Free Exchange

Free Exchange