How to Choose a Miniature Motor?

In designing ever-smaller devices, engineers face the challenge of making things move. The demand for smaller motors increases as the size of equipment decreases. In many cases, small enough motors do not exist, or if they do, they do not provide enough torque or speed to be useful in the application in question. It is often the only option to use a large framed motor and shrink everything else around it. Engineers are forced to compromise on their device's footprint because of the bottleneck of motion control. To ensure the best performance for you, we overcome difficulties such as motor heating, lifetime, torque attenuation, vibration, noise, and reliability.

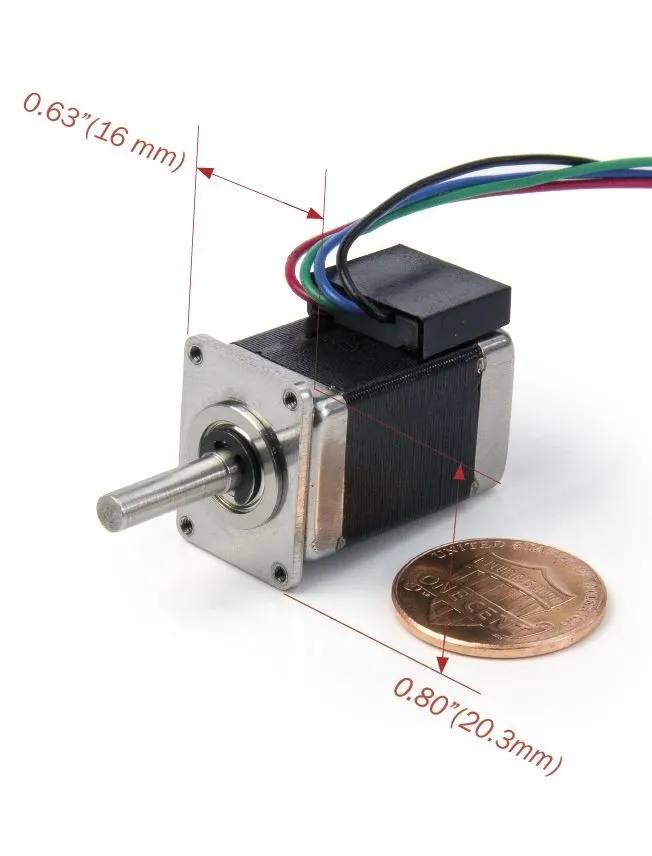

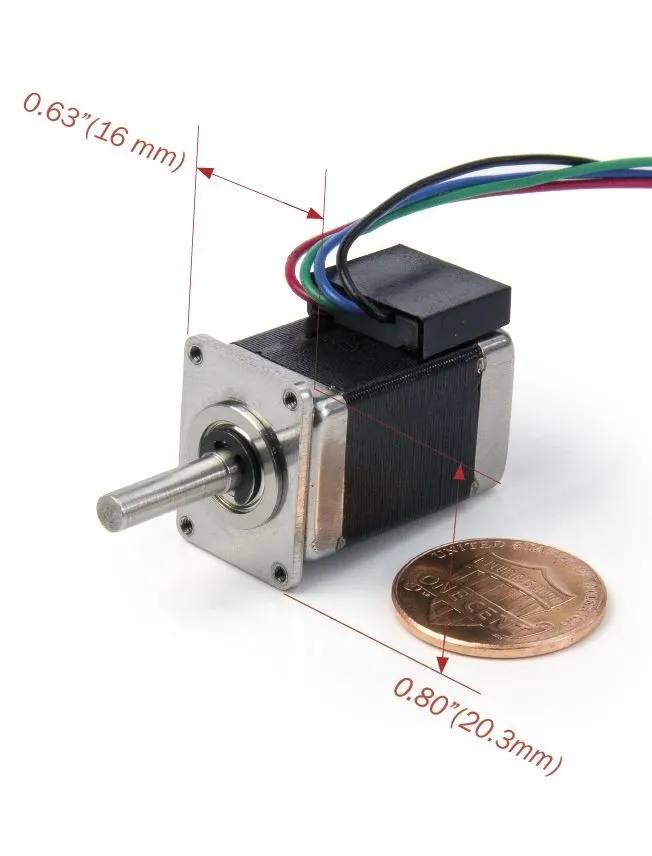

MOONS' never stopped researching and developing miniaturization applications. We provide a variety of mounting and connection modes for NEMA 8 hybrid stepper motors. Customers have the flexibility to design small, compact equipment that is easy to assemble. The mini linear stepper motor structure is compact in structure with the minimum size of NEMA8, easy to the overall design. The motors can directly connect with the cantilever mechanism, which saves the installation space of the coupling. This feature makes the mechanism exquisite and simple, without an intermediary transmission link, and ensures a higher degree of precision, efficiency, and longevity.

MOONS' never stopped researching and developing miniaturization applications. We provide a variety of mounting and connection modes for NEMA 8 hybrid stepper motors. Customers have the flexibility to design small, compact equipment that is easy to assemble. The mini linear stepper motor structure is compact in structure with the minimum size of NEMA8, easy to the overall design. The motors can directly connect with the cantilever mechanism, which saves the installation space of the coupling. This feature makes the mechanism exquisite and simple, without an intermediary transmission link, and ensures a higher degree of precision, efficiency, and longevity.  Our mini NEMA 6 hybrid stepper motor is what many Engineers have been waiting for. As a result, many of the problems associated with motion control are eliminated, which prevented equipment from becoming smaller. Our experience in the field of hybrid stepper motor technology enabled us to succeed where others have failed. We have successfully developed a stepper motor that is NEMA 6-sized and delivers adequate performance. As compared to other motors of similar size, the 106 delivers greater torque at higher speeds and with greater accuracy.

Our mini NEMA 6 hybrid stepper motor is what many Engineers have been waiting for. As a result, many of the problems associated with motion control are eliminated, which prevented equipment from becoming smaller. Our experience in the field of hybrid stepper motor technology enabled us to succeed where others have failed. We have successfully developed a stepper motor that is NEMA 6-sized and delivers adequate performance. As compared to other motors of similar size, the 106 delivers greater torque at higher speeds and with greater accuracy.  In the field of PM stepper motors, we provide miniature permanent magnet stepper motors with outer diameters of 15mm, 20mm, 25mm, 35mm, and 42mm. When you couple it with a gearbox, you can greatly improve step accuracy and torque. Generally, permanent magnet stepping motors have a step angle of 3.75 degrees, 7.5 degrees, 15 degrees, or 18 degrees. MOONS' PM stepper motors are widely applied in many innovative applications, including computer equipment, photographic systems, optoelectronic devices, valve control, ATM equipment, CNC machine, automatic winding machines, electronic clocks, and medical equipment.

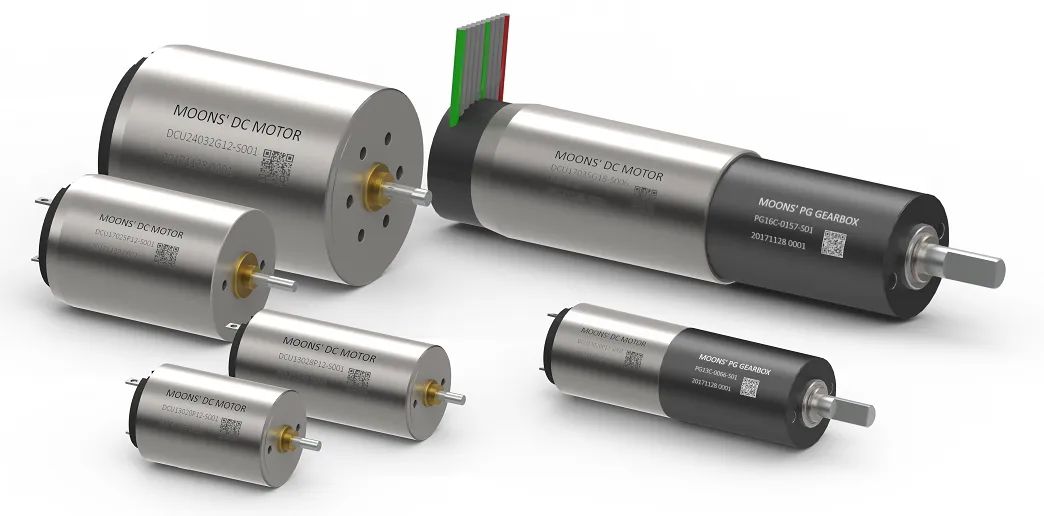

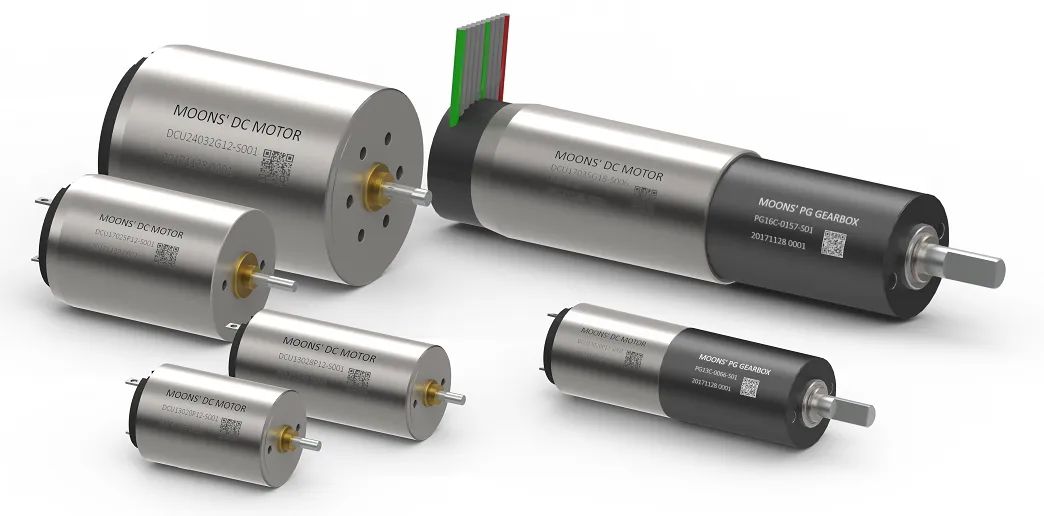

In the field of PM stepper motors, we provide miniature permanent magnet stepper motors with outer diameters of 15mm, 20mm, 25mm, 35mm, and 42mm. When you couple it with a gearbox, you can greatly improve step accuracy and torque. Generally, permanent magnet stepping motors have a step angle of 3.75 degrees, 7.5 degrees, 15 degrees, or 18 degrees. MOONS' PM stepper motors are widely applied in many innovative applications, including computer equipment, photographic systems, optoelectronic devices, valve control, ATM equipment, CNC machine, automatic winding machines, electronic clocks, and medical equipment.  In the field of BLDC motors, we provide small brushless dc motors with outer diameters of 16mm, 22mm, 30mm, and 36mm. The advantages of a brushless motor over brushed motors are a high power-to-weight ratio, high speed, and electronic control. MOONS' offers a comprehensive selection of 3W~300W high-performance brushless motors used in a wide variety of applications, including textile machines, ATMs, printers, solar energy equipment, pump, the food industry, and sorting equipment.

In the field of BLDC motors, we provide small brushless dc motors with outer diameters of 16mm, 22mm, 30mm, and 36mm. The advantages of a brushless motor over brushed motors are a high power-to-weight ratio, high speed, and electronic control. MOONS' offers a comprehensive selection of 3W~300W high-performance brushless motors used in a wide variety of applications, including textile machines, ATMs, printers, solar energy equipment, pump, the food industry, and sorting equipment.  In the field of slotless brushless dc motors, we provide micro-slotless dc motors with an outer diameter of 13mm, which uses our ironless winding, bringing high torque and power density in such a small package. This motor gets a compact design and runs up to about 50,000 rpm speed. The micromotor length is 37.4mm and the holding torque is up to 5.55mNm. With no cogging, the operational lifetime is up to 20,000 hours. And the encoder can be used in accurate positioning applications. In the field of coreless brushed dc motors, we provide three types of coreless motors whose diameters are 13mm, 17mm, and 24mm as options. MOONS' coreless DC motors differ from conventional iron core DC motors in that the rotor consists of a self-supporting lap winding. Innovative ironless winding helps our motor to achieve the best performance. Our product is also available with a driver that makes it perfect for small applications such as pipettes, spectrophotometers, sample pretreatment platforms, precision balances, and micro diaphragm pumps.

In the field of slotless brushless dc motors, we provide micro-slotless dc motors with an outer diameter of 13mm, which uses our ironless winding, bringing high torque and power density in such a small package. This motor gets a compact design and runs up to about 50,000 rpm speed. The micromotor length is 37.4mm and the holding torque is up to 5.55mNm. With no cogging, the operational lifetime is up to 20,000 hours. And the encoder can be used in accurate positioning applications. In the field of coreless brushed dc motors, we provide three types of coreless motors whose diameters are 13mm, 17mm, and 24mm as options. MOONS' coreless DC motors differ from conventional iron core DC motors in that the rotor consists of a self-supporting lap winding. Innovative ironless winding helps our motor to achieve the best performance. Our product is also available with a driver that makes it perfect for small applications such as pipettes, spectrophotometers, sample pretreatment platforms, precision balances, and micro diaphragm pumps.  Miniature stepper motors are suitable for miniaturized applications with the following requirements: ● Low cost for control achieved ● High torque at startup and low speeds ● Ruggedness ● Can operate in an open loop control system ● Low maintenance ● Precise positioning and repeatability of movement high-reliability Small BLDC motors are suitable for miniaturized applications with the following requirements: ● Wide range of speed control and smooth torque output excellent speed stability ● Small size, high power ● Low-temperature rise, low noise, low vibration ● Long life, low maintenance costs ● Low positioning torque ● Energy efficient

Miniature stepper motors are suitable for miniaturized applications with the following requirements: ● Low cost for control achieved ● High torque at startup and low speeds ● Ruggedness ● Can operate in an open loop control system ● Low maintenance ● Precise positioning and repeatability of movement high-reliability Small BLDC motors are suitable for miniaturized applications with the following requirements: ● Wide range of speed control and smooth torque output excellent speed stability ● Small size, high power ● Low-temperature rise, low noise, low vibration ● Long life, low maintenance costs ● Low positioning torque ● Energy efficient

MOONS' never stopped researching and developing miniaturization applications. We provide a variety of mounting and connection modes for NEMA 8 hybrid stepper motors. Customers have the flexibility to design small, compact equipment that is easy to assemble. The mini linear stepper motor structure is compact in structure with the minimum size of NEMA8, easy to the overall design. The motors can directly connect with the cantilever mechanism, which saves the installation space of the coupling. This feature makes the mechanism exquisite and simple, without an intermediary transmission link, and ensures a higher degree of precision, efficiency, and longevity.

MOONS' never stopped researching and developing miniaturization applications. We provide a variety of mounting and connection modes for NEMA 8 hybrid stepper motors. Customers have the flexibility to design small, compact equipment that is easy to assemble. The mini linear stepper motor structure is compact in structure with the minimum size of NEMA8, easy to the overall design. The motors can directly connect with the cantilever mechanism, which saves the installation space of the coupling. This feature makes the mechanism exquisite and simple, without an intermediary transmission link, and ensures a higher degree of precision, efficiency, and longevity.  Our mini NEMA 6 hybrid stepper motor is what many Engineers have been waiting for. As a result, many of the problems associated with motion control are eliminated, which prevented equipment from becoming smaller. Our experience in the field of hybrid stepper motor technology enabled us to succeed where others have failed. We have successfully developed a stepper motor that is NEMA 6-sized and delivers adequate performance. As compared to other motors of similar size, the 106 delivers greater torque at higher speeds and with greater accuracy.

Our mini NEMA 6 hybrid stepper motor is what many Engineers have been waiting for. As a result, many of the problems associated with motion control are eliminated, which prevented equipment from becoming smaller. Our experience in the field of hybrid stepper motor technology enabled us to succeed where others have failed. We have successfully developed a stepper motor that is NEMA 6-sized and delivers adequate performance. As compared to other motors of similar size, the 106 delivers greater torque at higher speeds and with greater accuracy.  In the field of PM stepper motors, we provide miniature permanent magnet stepper motors with outer diameters of 15mm, 20mm, 25mm, 35mm, and 42mm. When you couple it with a gearbox, you can greatly improve step accuracy and torque. Generally, permanent magnet stepping motors have a step angle of 3.75 degrees, 7.5 degrees, 15 degrees, or 18 degrees. MOONS' PM stepper motors are widely applied in many innovative applications, including computer equipment, photographic systems, optoelectronic devices, valve control, ATM equipment, CNC machine, automatic winding machines, electronic clocks, and medical equipment.

In the field of PM stepper motors, we provide miniature permanent magnet stepper motors with outer diameters of 15mm, 20mm, 25mm, 35mm, and 42mm. When you couple it with a gearbox, you can greatly improve step accuracy and torque. Generally, permanent magnet stepping motors have a step angle of 3.75 degrees, 7.5 degrees, 15 degrees, or 18 degrees. MOONS' PM stepper motors are widely applied in many innovative applications, including computer equipment, photographic systems, optoelectronic devices, valve control, ATM equipment, CNC machine, automatic winding machines, electronic clocks, and medical equipment.  In the field of BLDC motors, we provide small brushless dc motors with outer diameters of 16mm, 22mm, 30mm, and 36mm. The advantages of a brushless motor over brushed motors are a high power-to-weight ratio, high speed, and electronic control. MOONS' offers a comprehensive selection of 3W~300W high-performance brushless motors used in a wide variety of applications, including textile machines, ATMs, printers, solar energy equipment, pump, the food industry, and sorting equipment.

In the field of BLDC motors, we provide small brushless dc motors with outer diameters of 16mm, 22mm, 30mm, and 36mm. The advantages of a brushless motor over brushed motors are a high power-to-weight ratio, high speed, and electronic control. MOONS' offers a comprehensive selection of 3W~300W high-performance brushless motors used in a wide variety of applications, including textile machines, ATMs, printers, solar energy equipment, pump, the food industry, and sorting equipment.  In the field of slotless brushless dc motors, we provide micro-slotless dc motors with an outer diameter of 13mm, which uses our ironless winding, bringing high torque and power density in such a small package. This motor gets a compact design and runs up to about 50,000 rpm speed. The micromotor length is 37.4mm and the holding torque is up to 5.55mNm. With no cogging, the operational lifetime is up to 20,000 hours. And the encoder can be used in accurate positioning applications. In the field of coreless brushed dc motors, we provide three types of coreless motors whose diameters are 13mm, 17mm, and 24mm as options. MOONS' coreless DC motors differ from conventional iron core DC motors in that the rotor consists of a self-supporting lap winding. Innovative ironless winding helps our motor to achieve the best performance. Our product is also available with a driver that makes it perfect for small applications such as pipettes, spectrophotometers, sample pretreatment platforms, precision balances, and micro diaphragm pumps.

In the field of slotless brushless dc motors, we provide micro-slotless dc motors with an outer diameter of 13mm, which uses our ironless winding, bringing high torque and power density in such a small package. This motor gets a compact design and runs up to about 50,000 rpm speed. The micromotor length is 37.4mm and the holding torque is up to 5.55mNm. With no cogging, the operational lifetime is up to 20,000 hours. And the encoder can be used in accurate positioning applications. In the field of coreless brushed dc motors, we provide three types of coreless motors whose diameters are 13mm, 17mm, and 24mm as options. MOONS' coreless DC motors differ from conventional iron core DC motors in that the rotor consists of a self-supporting lap winding. Innovative ironless winding helps our motor to achieve the best performance. Our product is also available with a driver that makes it perfect for small applications such as pipettes, spectrophotometers, sample pretreatment platforms, precision balances, and micro diaphragm pumps.  Miniature stepper motors are suitable for miniaturized applications with the following requirements: ● Low cost for control achieved ● High torque at startup and low speeds ● Ruggedness ● Can operate in an open loop control system ● Low maintenance ● Precise positioning and repeatability of movement high-reliability Small BLDC motors are suitable for miniaturized applications with the following requirements: ● Wide range of speed control and smooth torque output excellent speed stability ● Small size, high power ● Low-temperature rise, low noise, low vibration ● Long life, low maintenance costs ● Low positioning torque ● Energy efficient

Miniature stepper motors are suitable for miniaturized applications with the following requirements: ● Low cost for control achieved ● High torque at startup and low speeds ● Ruggedness ● Can operate in an open loop control system ● Low maintenance ● Precise positioning and repeatability of movement high-reliability Small BLDC motors are suitable for miniaturized applications with the following requirements: ● Wide range of speed control and smooth torque output excellent speed stability ● Small size, high power ● Low-temperature rise, low noise, low vibration ● Long life, low maintenance costs ● Low positioning torque ● Energy efficient