Motion control solution for lithium battery producer

1. Brief introduction of automatic lithium battery producer equipment

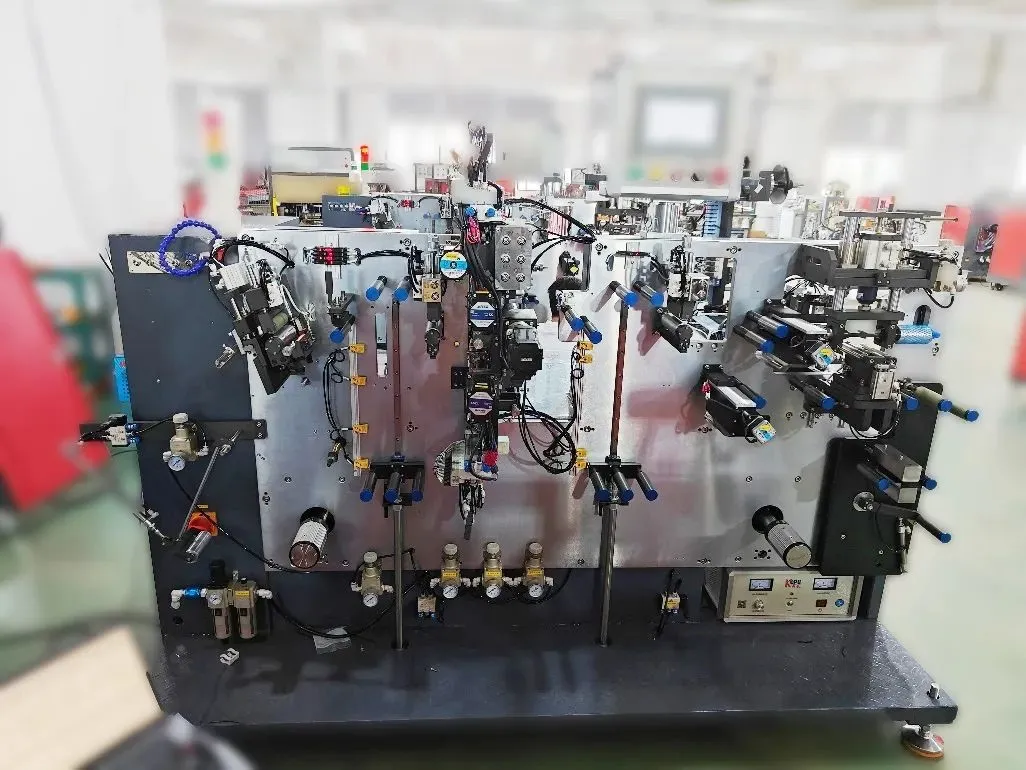

The fully automated lithium battery producer is designed to weld the tab to the plate, affix adhesive paper to the solder tab, and then collect the material or cut it into pieces. Automatic lithium battery producer equipment

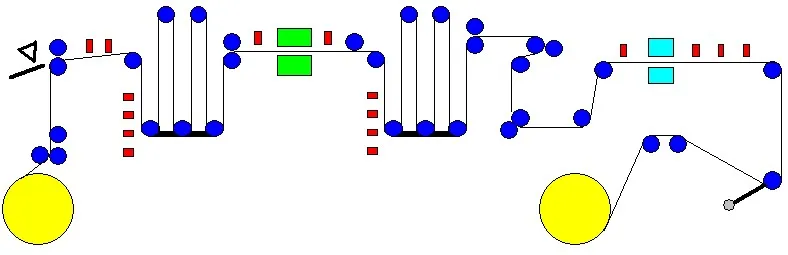

Automatic lithium battery producer equipment  Automatic lithium battery producer equipment simplified drawing Performance index of automatic lithium battery producer Plate type: positive and negative plate Plate length: 60-1000mm Production speed: 60-70 pieces /min Production accuracy: width error ±0.2mm, snaking error of plate less than ±0.5/1000mm

Automatic lithium battery producer equipment simplified drawing Performance index of automatic lithium battery producer Plate type: positive and negative plate Plate length: 60-1000mm Production speed: 60-70 pieces /min Production accuracy: width error ±0.2mm, snaking error of plate less than ±0.5/1000mm 2.Automatic lithium battery production machine process

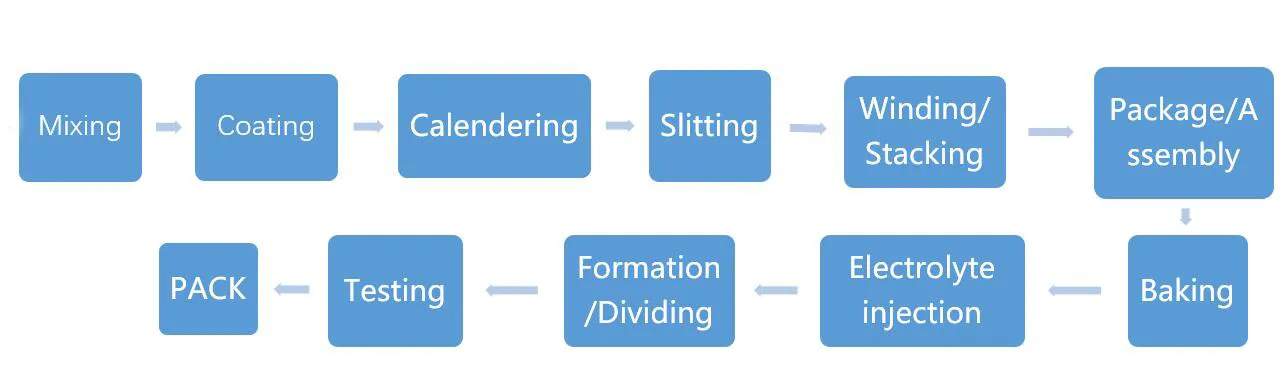

Automatic lithium battery production machine process In the lithium battery manufacturing process, the film process occurs after coating and cutting and before winding. These parentheses are added because, in some process designs, production and winding are integrated into one process, while in others, they are separate. In the design process of the battery tab, the battery tab differs from the unipolar tab and the multipolar tab. Unipolar tab: the positive and negative poles each have a tab; Multipolar ear: The number of positive and negative tabs is greater than one. Most of the general combination batteries are multi- tab, and single batteries with high current requirements are also multi- tab, however, the manufacturing process of multi- tab batteries is separate, where an electrode lug is welded to each positive and negative electrode piece, and then transferred to the subsequent process. Production process flow

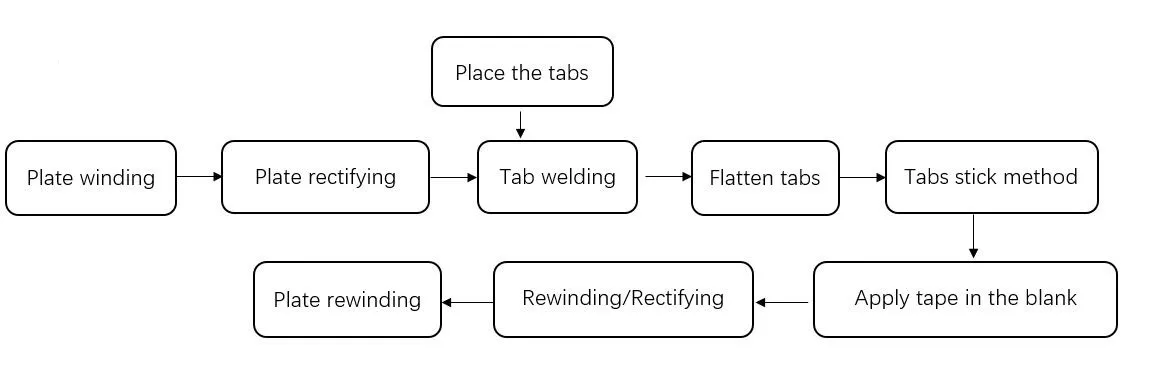

Automatic lithium battery production machine process In the lithium battery manufacturing process, the film process occurs after coating and cutting and before winding. These parentheses are added because, in some process designs, production and winding are integrated into one process, while in others, they are separate. In the design process of the battery tab, the battery tab differs from the unipolar tab and the multipolar tab. Unipolar tab: the positive and negative poles each have a tab; Multipolar ear: The number of positive and negative tabs is greater than one. Most of the general combination batteries are multi- tab, and single batteries with high current requirements are also multi- tab, however, the manufacturing process of multi- tab batteries is separate, where an electrode lug is welded to each positive and negative electrode piece, and then transferred to the subsequent process. Production process flow  Production process flow

Production process flow 3. MOONS' motion control solution

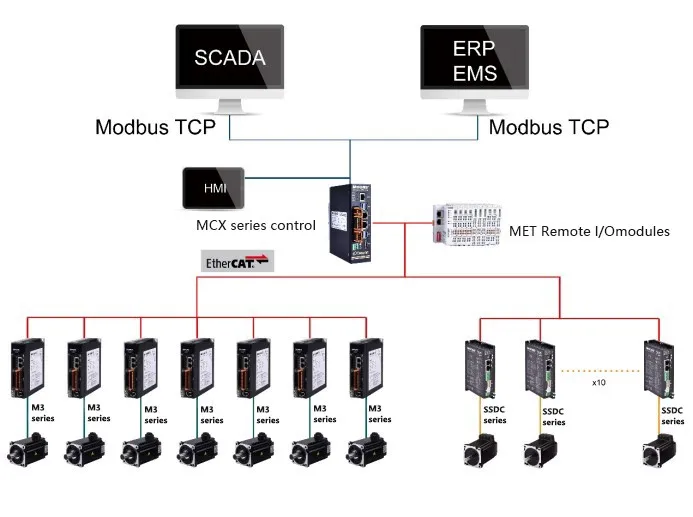

The control system of this scheme uses MOONS' to develop an eXtreme series high-performance motion controller, which is suitable for a variety of high-speed and high-precision motion controller applications. It combines motion control, logic control, network communication, and other functions, and is the heart of the automation solution. Motion control solution topology diagram Difficulty 1: Precise tension control to ensure the position accuracy of different types of plate welding tab and adhesive paper. Solution: Due to the fact that the welding tab and adhesive paper rely on the plate movement for an accurate position, the stable tension control ensures the stability of the plate movement process, thus ensuring a higher degree of accuracy for the welding position and adhesive position. Difficulty 2: Using "flying shear" function, continuous glue, improve production efficiency. Solution: The original adhesive is pressed by the upper and lower cylinders, and the plate needs to stop when it passes the adhesive position. The synchronous rotary pressing method is adopted, similar to the flying shear method, and the plate continuously passes through the adhesive position, greatly shortening the adhesive time and improving the production efficiency. Advantages of the scheme: The whole system uses Naruto MOONS' series products: motion controller, servo driver, servo motor, stepper driver, stepper motor. • Book type controller and servo, save space of electric control cabinet. • One-stop service, shorten the development cycle.

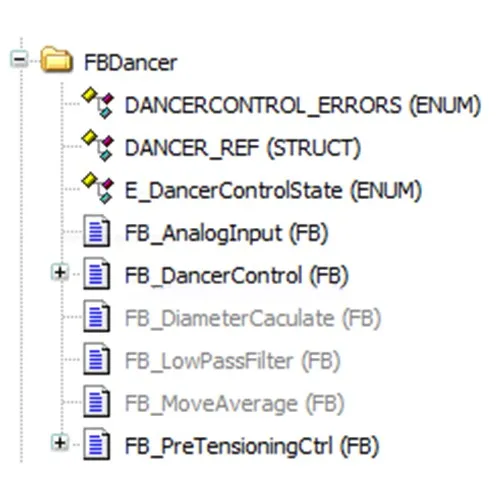

Motion control solution topology diagram Difficulty 1: Precise tension control to ensure the position accuracy of different types of plate welding tab and adhesive paper. Solution: Due to the fact that the welding tab and adhesive paper rely on the plate movement for an accurate position, the stable tension control ensures the stability of the plate movement process, thus ensuring a higher degree of accuracy for the welding position and adhesive position. Difficulty 2: Using "flying shear" function, continuous glue, improve production efficiency. Solution: The original adhesive is pressed by the upper and lower cylinders, and the plate needs to stop when it passes the adhesive position. The synchronous rotary pressing method is adopted, similar to the flying shear method, and the plate continuously passes through the adhesive position, greatly shortening the adhesive time and improving the production efficiency. Advantages of the scheme: The whole system uses Naruto MOONS' series products: motion controller, servo driver, servo motor, stepper driver, stepper motor. • Book type controller and servo, save space of electric control cabinet. • One-stop service, shorten the development cycle.  Process bank Unique tension control library that is easy to use, accurate, modular, and can be used to shorten the programming debugging process.

Process bank Unique tension control library that is easy to use, accurate, modular, and can be used to shorten the programming debugging process.