Service Life of a Stepper Motor

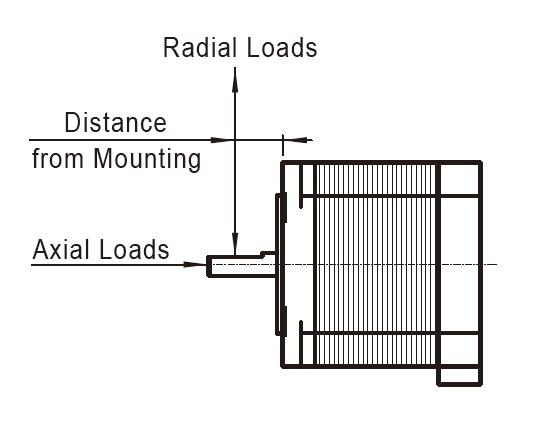

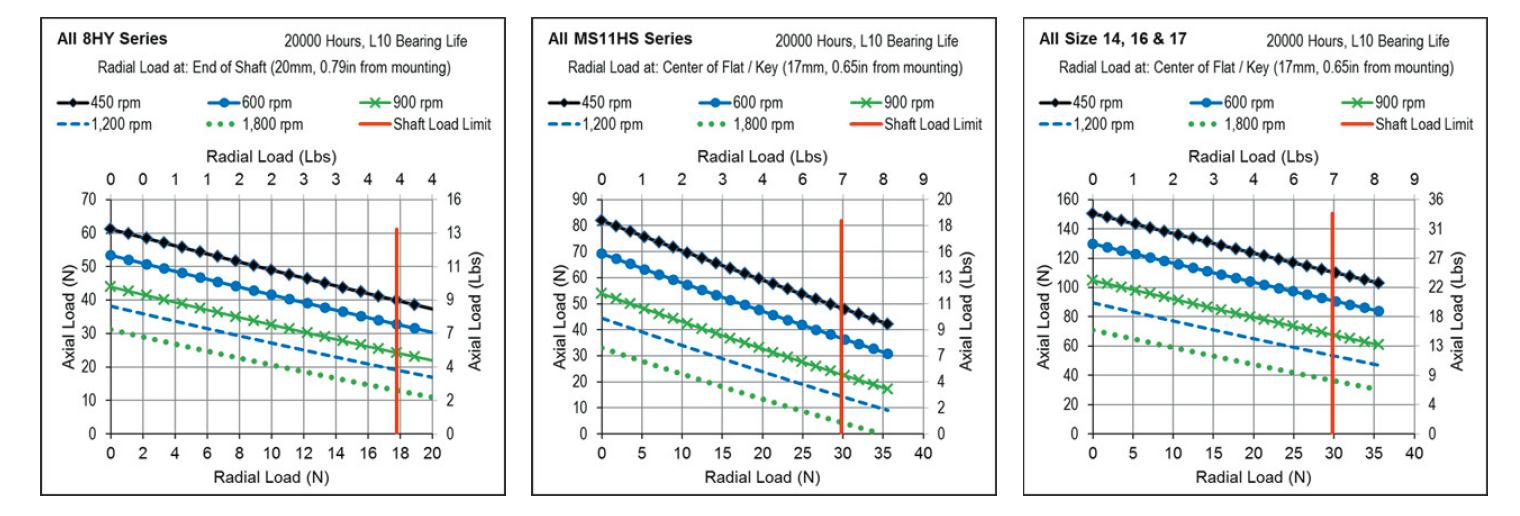

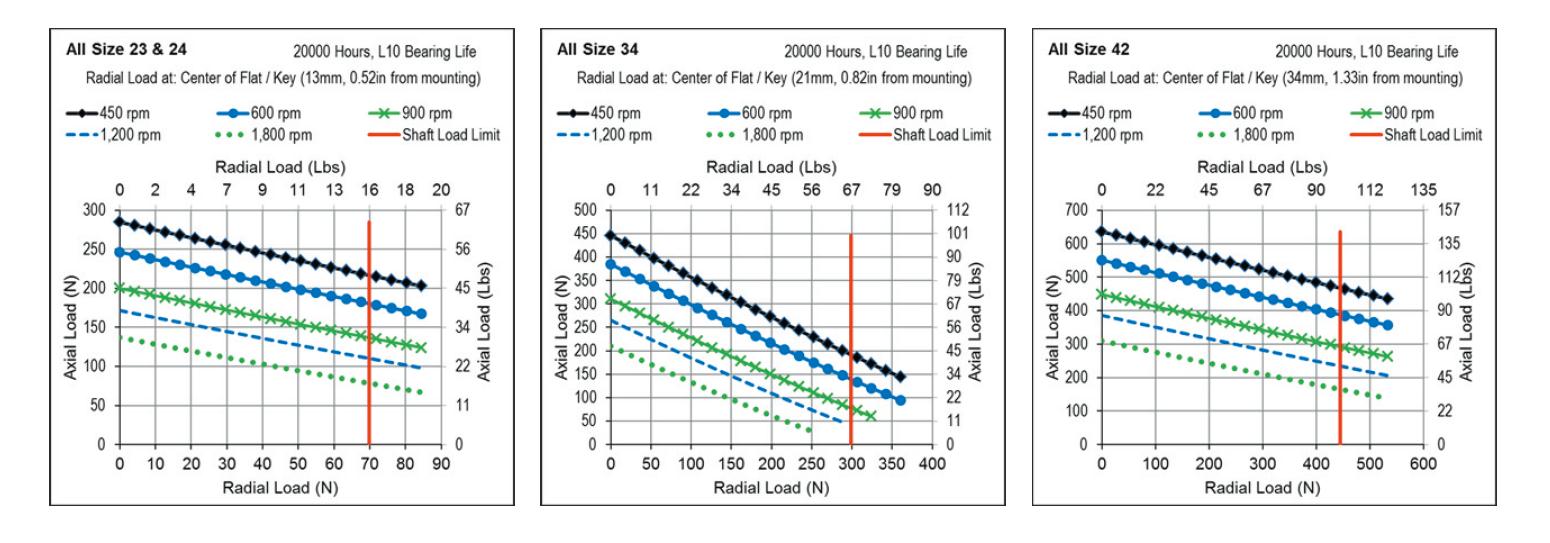

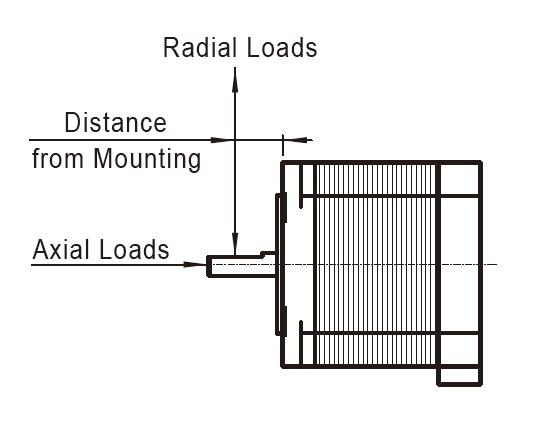

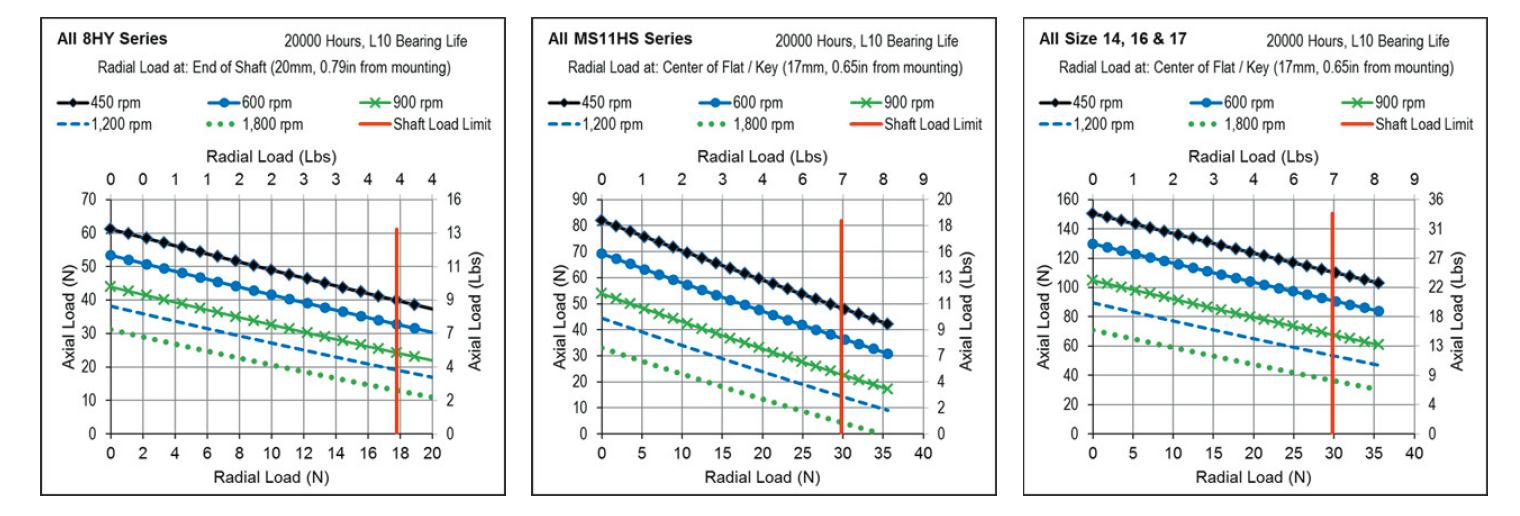

The life of a stepper motor is usually determined by the life of its bearings. In general, bearings are specified as having a life of 10 years (outside the United States, it may be referred to as a life of 10 years). This is the life at which ten percent of the bearings in that application are expected to have failed due to classical fatigue failure (and not any other mode of failure such as lubrication starvation, incorrect mounting, etc.), or, alternatively, the life at which ninety percent will still be functioning. It is important to note that the L10 life of a bearing is only a theoretical estimate and may not be indicative of its actual service life. The C0(static loading) value is also used to rate bearings. Rather than an actual load value, this is a reference load rating. In addition to load, temperature, maintenance, lubrication, material defects, contamination, handling, and installation, rolling element-bearing life is also affected by these factors. All of these factors can have a significant impact on the life of a bearing.  The following bearing life curves illustrate the maximum axial and radial loads for 20,000 hours of L10 bearing life at various speeds. It is highly dependent on the distance from the mounting face where the load is applied that the shaft radial load limit (and bearing load ratings) are determined. The curves were calculated using the radial load at the distance from the mounting face (usually the center of the flat or keyway). High radial loads created by a pulley attached to the motor shaft at a large distance from the mounting face and a tight belt are common causes of shaft (and bearing) failure. Ensure that pulleys and gears are mounted as close to the motor's face as possible, and avoid overtightening belts. As a result, shaft stress will be reduced significantly, and bearing life will be increased.

The following bearing life curves illustrate the maximum axial and radial loads for 20,000 hours of L10 bearing life at various speeds. It is highly dependent on the distance from the mounting face where the load is applied that the shaft radial load limit (and bearing load ratings) are determined. The curves were calculated using the radial load at the distance from the mounting face (usually the center of the flat or keyway). High radial loads created by a pulley attached to the motor shaft at a large distance from the mounting face and a tight belt are common causes of shaft (and bearing) failure. Ensure that pulleys and gears are mounted as close to the motor's face as possible, and avoid overtightening belts. As a result, shaft stress will be reduced significantly, and bearing life will be increased.  Bearing Life Curves

Bearing Life Curves  Bearing Life Curves

Bearing Life Curves

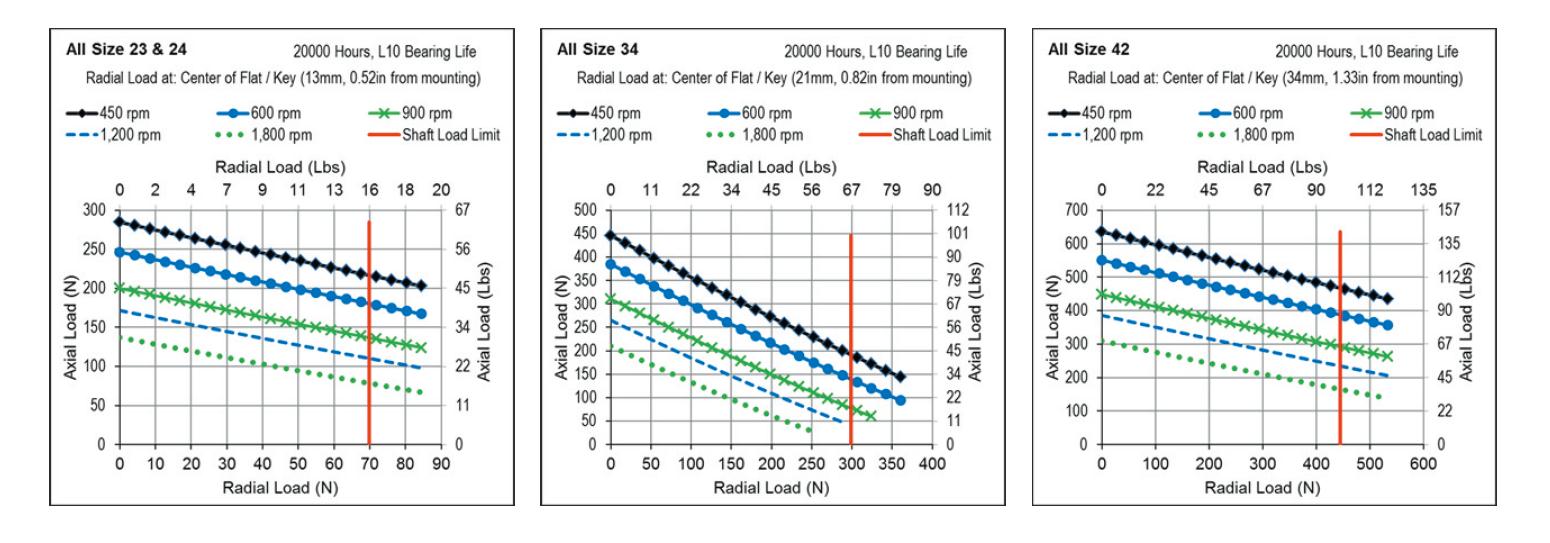

The following bearing life curves illustrate the maximum axial and radial loads for 20,000 hours of L10 bearing life at various speeds. It is highly dependent on the distance from the mounting face where the load is applied that the shaft radial load limit (and bearing load ratings) are determined. The curves were calculated using the radial load at the distance from the mounting face (usually the center of the flat or keyway). High radial loads created by a pulley attached to the motor shaft at a large distance from the mounting face and a tight belt are common causes of shaft (and bearing) failure. Ensure that pulleys and gears are mounted as close to the motor's face as possible, and avoid overtightening belts. As a result, shaft stress will be reduced significantly, and bearing life will be increased.

The following bearing life curves illustrate the maximum axial and radial loads for 20,000 hours of L10 bearing life at various speeds. It is highly dependent on the distance from the mounting face where the load is applied that the shaft radial load limit (and bearing load ratings) are determined. The curves were calculated using the radial load at the distance from the mounting face (usually the center of the flat or keyway). High radial loads created by a pulley attached to the motor shaft at a large distance from the mounting face and a tight belt are common causes of shaft (and bearing) failure. Ensure that pulleys and gears are mounted as close to the motor's face as possible, and avoid overtightening belts. As a result, shaft stress will be reduced significantly, and bearing life will be increased.  Bearing Life Curves

Bearing Life Curves  Bearing Life Curves

Bearing Life Curves