Stepper Drives and PowerPlus Motors from MOONS' Industries

Manufacturers often redesign motors with greater torque to achieve greater acceleration to improve the performance of a machine or solve stalling problems. Retrofitting a stepper motor, however, is a time-consuming and expensive process, since it requires machining new mounting brackets and increasing the drive size and power supply. PowerPlus Hybrid Stepper Motors from MOONS' Industries eliminate the hassle of resizing motors by providing 25% to 40% more torque across the entire speed range of a motor. With the same physical dimensions as standard NEMA 23, 24, and 34 stepper motors, PowerPlus Hybrid Stepper Motors often drop into place to minimize upgrade costs while improving performance. The increased torque of the PowerPlus technology may be attributed to the higher motor efficiency. As a result of the higher magnetic flux density within the motor, the PowerPlus Stepper Motor performs better. This enables it to generate up to 40% more torque than conventional motors. Magnets placed between the stator teeth redirect and refocus most of the stray magnetic flux into the stator teeth to produce additional torque with the same input power. For more details, please read our article about "MOONS' Stepper Motor PowerPlus Technology"  In a typical application of upgrading stepper motor performance with PowerPlus technology, a manufacturer of CNC cutting systems is seeking to produce a high-performance version of its current machine to increase cutting speeds by 75% to 100% and enhance move speed smoothly without resonance.

In a typical application of upgrading stepper motor performance with PowerPlus technology, a manufacturer of CNC cutting systems is seeking to produce a high-performance version of its current machine to increase cutting speeds by 75% to 100% and enhance move speed smoothly without resonance.

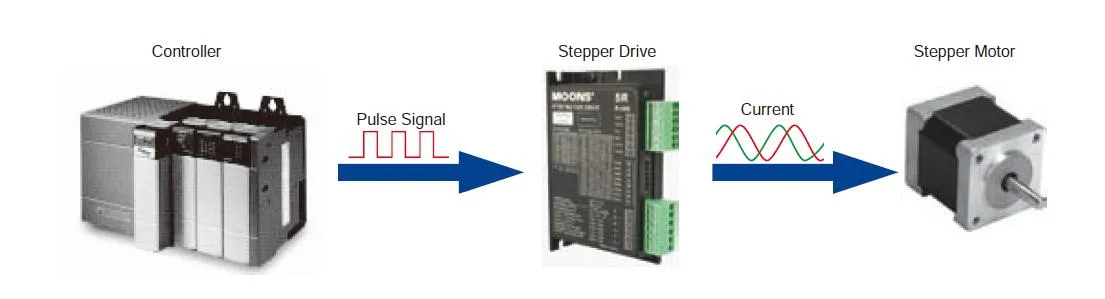

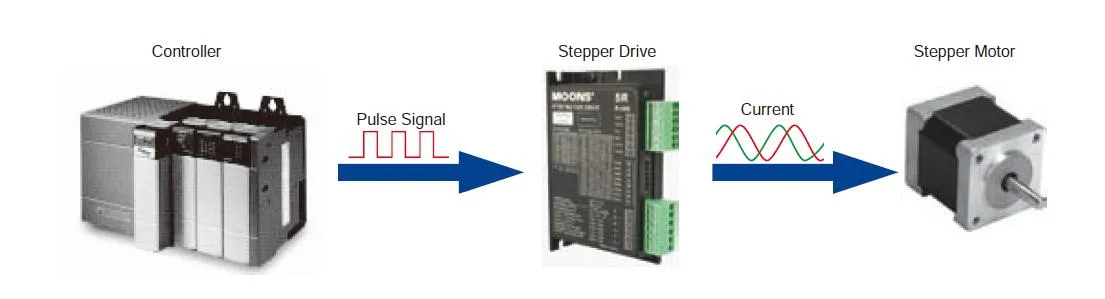

As part of the development of this new product, the CNC manufacturer wishes to minimize engineering time while limiting parts inventory. A PowerPlus Stepper Motor provides twice the additional power over the existing motor needed for the new CNC machine without redesigning new parts. MOONS' SR series micro-step stepper drive provides a broad range of output current with a compact size, the anti-resonance function increases torque, and the micro-step emulation ensures smooth movement. Meanwhile, Idle current reduction reduces motor heating. In fact, by using PowerPlus motors and SR drives, the machine builder can use a smaller size motor and drive system to reach the same performance in a smaller and more cost-effective package.  For more information on the PowerPlus motors, visit: https://www.moonsindustries.com/c/powerplus-hybrid-stepper-motors-a020102 For more information on SR series stepper drive, visit: https://www.moonsindustries.com/series/sr-series-two-phase-dc-stepper-motor-drives-b01020101

For more information on the PowerPlus motors, visit: https://www.moonsindustries.com/c/powerplus-hybrid-stepper-motors-a020102 For more information on SR series stepper drive, visit: https://www.moonsindustries.com/series/sr-series-two-phase-dc-stepper-motor-drives-b01020101

In a typical application of upgrading stepper motor performance with PowerPlus technology, a manufacturer of CNC cutting systems is seeking to produce a high-performance version of its current machine to increase cutting speeds by 75% to 100% and enhance move speed smoothly without resonance.

In a typical application of upgrading stepper motor performance with PowerPlus technology, a manufacturer of CNC cutting systems is seeking to produce a high-performance version of its current machine to increase cutting speeds by 75% to 100% and enhance move speed smoothly without resonance. | Machine Specs of Current Machine | Machine Specs of High-Performance Machine | |

| Rapid move speed: | 300 rpm | 600 rpm |

| Cutting speed: | 150 rpm | 300 rpm |

| Power supply output: | 24 VDC @ 5 A | 24 VDC @ 5 A |

| Stepper drive output: | 1.5 A | 1.5 A |

| Motor holding toque: | 210 oz-in. | 330 oz-in. |

For more information on the PowerPlus motors, visit: https://www.moonsindustries.com/c/powerplus-hybrid-stepper-motors-a020102 For more information on SR series stepper drive, visit: https://www.moonsindustries.com/series/sr-series-two-phase-dc-stepper-motor-drives-b01020101

For more information on the PowerPlus motors, visit: https://www.moonsindustries.com/c/powerplus-hybrid-stepper-motors-a020102 For more information on SR series stepper drive, visit: https://www.moonsindustries.com/series/sr-series-two-phase-dc-stepper-motor-drives-b01020101