Stepper Motor Step Angle and Calculation Formula

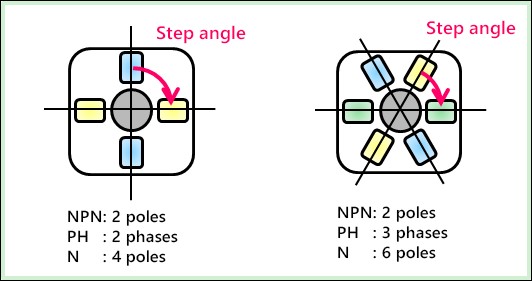

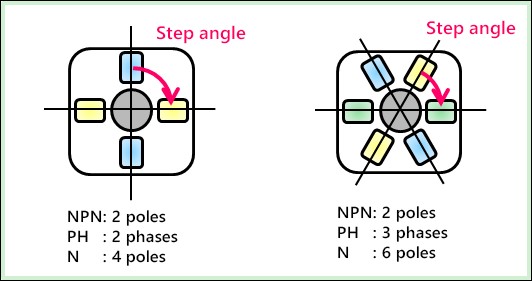

Definition of Stepper Motor Step Angle: When the stepper motor switches the excitation current of the stator winding once, the rotor rotates by a fixed angle, known as the step angle. The step angle is generally derived from the torque generated by the switched phase current, which is why the number of poles per phase needs to be an even number. Stepper motors typically have more than two phases; however, there are special single-phase stepper motors with only one coil. Although termed single-phase, these motors operate by reversing the direction of the magnetic flux generated by a single coil to drive the rotor's rotation. Common configurations of stepper motors include single-phase, two-phase, three-phase, four-phase, and five-phase motors. The step angle of a stepper motor is a fundamental property that determines the basis of its movement. The step angle is determined by the total number of magnetic poles in the motor. The formula to calculate the step angle is 360° divided by the total number of magnetic poles across all phases of the motor, as shown in the following formula: Step Angle = 360° / N Where the parameter N is calculated by multiplying the number of magnetic poles per phase (NPH) by the number of phases (PH): N = (NPH * PH) Parameter definition: NPH: number of magnetic poles per phase; PH: number of phases; N: total number of magnetic poles for each phase Motors are typically referred to by the configuration "PH phase/N pole motor".  The left side is 2-phase/4-pole, and the right side is 3-phase/6-pole

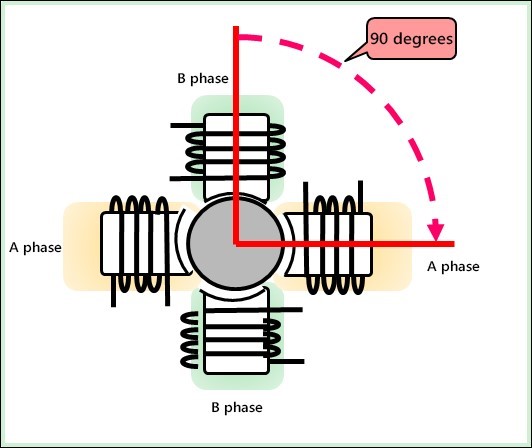

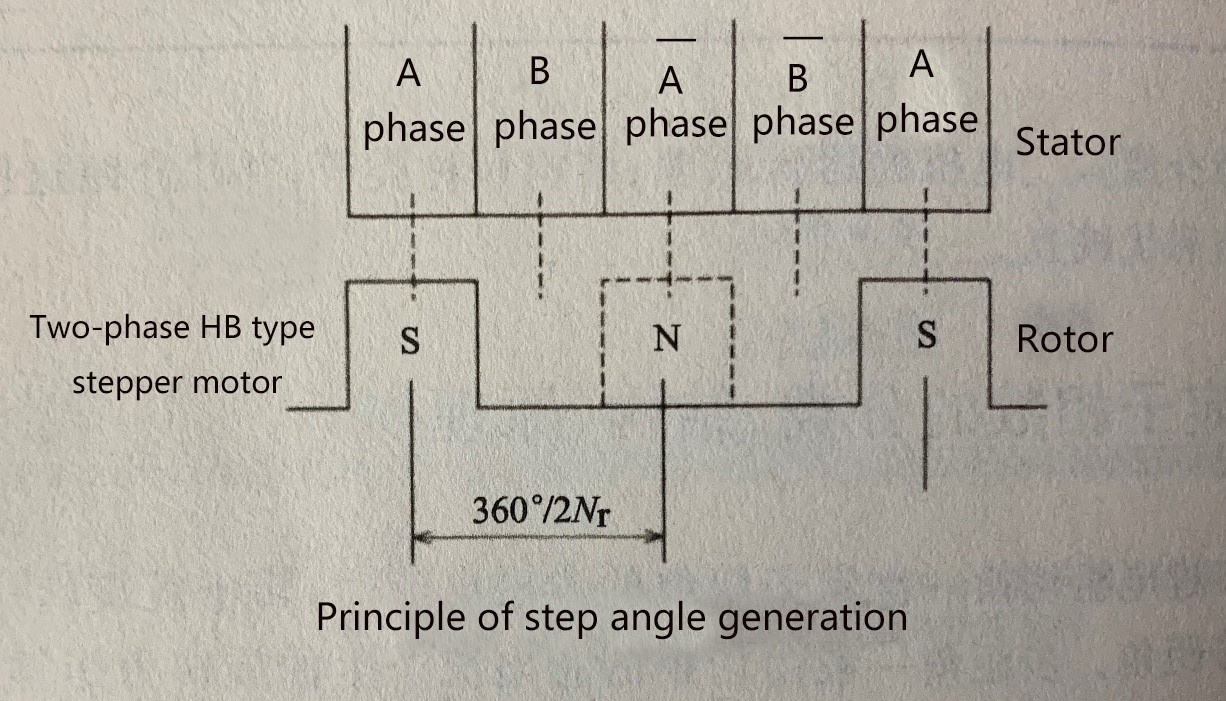

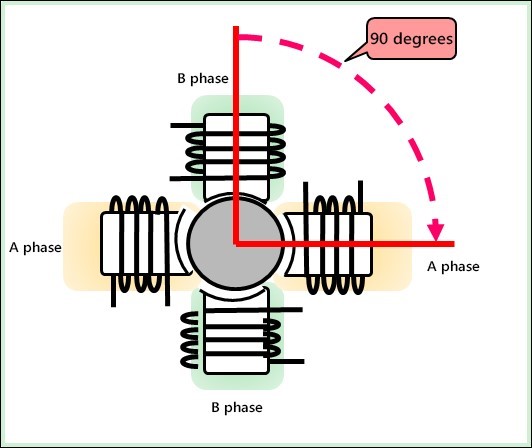

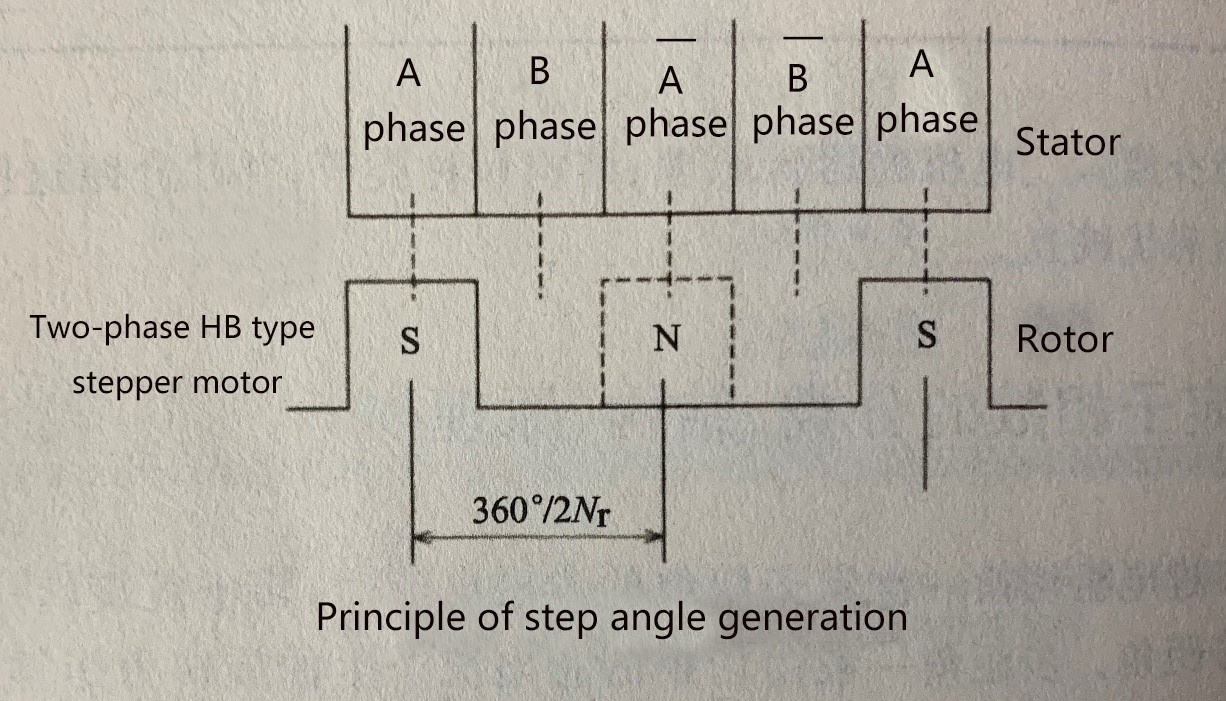

The left side is 2-phase/4-pole, and the right side is 3-phase/6-pole  If it is a 2-phase 4-pole motor, the step angle will be 90 degrees. The stepper motor rotates by continuously performing all stepping operations. The most common step angle for stepper motors is 1.8°, which allows for 200 steps per revolution. Some stepper motors, however, have smaller step angles, such as 0.9°. Motors with smaller step angles provide smoother operation and reduced vibration. Most stepper motors on the market today use permanent magnet rotors due to their high efficiency and high resolution. Classification of Stepper Motors with Step Angles of 1.8° and 0.9°: The resolution of the stepper motor is a factor that determines the step angle. The higher the resolution of the stepper motor (defined as the number of steps per revolution, 360° divided by the step angle), the higher the positional accuracy. Therefore, to achieve high resolution, a greater number of poles is required. In a PM type rotor, N and S poles are placed alternately and at equal pitches on the outer surface of the rotor core. The number of rotor poles is the sum of the N poles and S poles. Simply put, assuming the number of pole pairs is 1, the step angle θs of a stepper motor with a permanent magnet rotor is determined by the following formula: θs=180°/PNr Where Nr is the number of rotor pole pairs and P is the number of stator phases. The physical meaning of this formula is as follows: The mechanical angle of a rotor rotation is 360°. If divided by the number of poles, 2Nr, it is equivalent to the mechanical angle occupied by one pole, which is 180°/Nr. In other words, the mechanical angle of one pole, when divided by the number of stator phases, gives the step angle, as illustrated in the diagram below.

If it is a 2-phase 4-pole motor, the step angle will be 90 degrees. The stepper motor rotates by continuously performing all stepping operations. The most common step angle for stepper motors is 1.8°, which allows for 200 steps per revolution. Some stepper motors, however, have smaller step angles, such as 0.9°. Motors with smaller step angles provide smoother operation and reduced vibration. Most stepper motors on the market today use permanent magnet rotors due to their high efficiency and high resolution. Classification of Stepper Motors with Step Angles of 1.8° and 0.9°: The resolution of the stepper motor is a factor that determines the step angle. The higher the resolution of the stepper motor (defined as the number of steps per revolution, 360° divided by the step angle), the higher the positional accuracy. Therefore, to achieve high resolution, a greater number of poles is required. In a PM type rotor, N and S poles are placed alternately and at equal pitches on the outer surface of the rotor core. The number of rotor poles is the sum of the N poles and S poles. Simply put, assuming the number of pole pairs is 1, the step angle θs of a stepper motor with a permanent magnet rotor is determined by the following formula: θs=180°/PNr Where Nr is the number of rotor pole pairs and P is the number of stator phases. The physical meaning of this formula is as follows: The mechanical angle of a rotor rotation is 360°. If divided by the number of poles, 2Nr, it is equivalent to the mechanical angle occupied by one pole, which is 180°/Nr. In other words, the mechanical angle of one pole, when divided by the number of stator phases, gives the step angle, as illustrated in the diagram below.  It can also be seen from the above formula that the smaller the step angle, the higher the resolution. Therefore, to improve the resolution of the stepper motor, it is necessary to either increase the number of rotor pole pairs (Nr) or adopt a multi-phase method with a larger number of stator phases (P). However, the increase in Nr is limited by mechanical processing constraints, so manufacturing high-resolution stepper motors requires the combined use of both methods. The above information covers the step angles and calculation formulas for stepper motors. If you need to select a suitable stepper motor for your application, you can use the stepper motor selection tool provided by MOONS' (click to access the selection tool) or consult with a product manager.

It can also be seen from the above formula that the smaller the step angle, the higher the resolution. Therefore, to improve the resolution of the stepper motor, it is necessary to either increase the number of rotor pole pairs (Nr) or adopt a multi-phase method with a larger number of stator phases (P). However, the increase in Nr is limited by mechanical processing constraints, so manufacturing high-resolution stepper motors requires the combined use of both methods. The above information covers the step angles and calculation formulas for stepper motors. If you need to select a suitable stepper motor for your application, you can use the stepper motor selection tool provided by MOONS' (click to access the selection tool) or consult with a product manager.

The left side is 2-phase/4-pole, and the right side is 3-phase/6-pole

The left side is 2-phase/4-pole, and the right side is 3-phase/6-pole  If it is a 2-phase 4-pole motor, the step angle will be 90 degrees. The stepper motor rotates by continuously performing all stepping operations. The most common step angle for stepper motors is 1.8°, which allows for 200 steps per revolution. Some stepper motors, however, have smaller step angles, such as 0.9°. Motors with smaller step angles provide smoother operation and reduced vibration. Most stepper motors on the market today use permanent magnet rotors due to their high efficiency and high resolution. Classification of Stepper Motors with Step Angles of 1.8° and 0.9°: The resolution of the stepper motor is a factor that determines the step angle. The higher the resolution of the stepper motor (defined as the number of steps per revolution, 360° divided by the step angle), the higher the positional accuracy. Therefore, to achieve high resolution, a greater number of poles is required. In a PM type rotor, N and S poles are placed alternately and at equal pitches on the outer surface of the rotor core. The number of rotor poles is the sum of the N poles and S poles. Simply put, assuming the number of pole pairs is 1, the step angle θs of a stepper motor with a permanent magnet rotor is determined by the following formula: θs=180°/PNr Where Nr is the number of rotor pole pairs and P is the number of stator phases. The physical meaning of this formula is as follows: The mechanical angle of a rotor rotation is 360°. If divided by the number of poles, 2Nr, it is equivalent to the mechanical angle occupied by one pole, which is 180°/Nr. In other words, the mechanical angle of one pole, when divided by the number of stator phases, gives the step angle, as illustrated in the diagram below.

If it is a 2-phase 4-pole motor, the step angle will be 90 degrees. The stepper motor rotates by continuously performing all stepping operations. The most common step angle for stepper motors is 1.8°, which allows for 200 steps per revolution. Some stepper motors, however, have smaller step angles, such as 0.9°. Motors with smaller step angles provide smoother operation and reduced vibration. Most stepper motors on the market today use permanent magnet rotors due to their high efficiency and high resolution. Classification of Stepper Motors with Step Angles of 1.8° and 0.9°: The resolution of the stepper motor is a factor that determines the step angle. The higher the resolution of the stepper motor (defined as the number of steps per revolution, 360° divided by the step angle), the higher the positional accuracy. Therefore, to achieve high resolution, a greater number of poles is required. In a PM type rotor, N and S poles are placed alternately and at equal pitches on the outer surface of the rotor core. The number of rotor poles is the sum of the N poles and S poles. Simply put, assuming the number of pole pairs is 1, the step angle θs of a stepper motor with a permanent magnet rotor is determined by the following formula: θs=180°/PNr Where Nr is the number of rotor pole pairs and P is the number of stator phases. The physical meaning of this formula is as follows: The mechanical angle of a rotor rotation is 360°. If divided by the number of poles, 2Nr, it is equivalent to the mechanical angle occupied by one pole, which is 180°/Nr. In other words, the mechanical angle of one pole, when divided by the number of stator phases, gives the step angle, as illustrated in the diagram below.  It can also be seen from the above formula that the smaller the step angle, the higher the resolution. Therefore, to improve the resolution of the stepper motor, it is necessary to either increase the number of rotor pole pairs (Nr) or adopt a multi-phase method with a larger number of stator phases (P). However, the increase in Nr is limited by mechanical processing constraints, so manufacturing high-resolution stepper motors requires the combined use of both methods. The above information covers the step angles and calculation formulas for stepper motors. If you need to select a suitable stepper motor for your application, you can use the stepper motor selection tool provided by MOONS' (click to access the selection tool) or consult with a product manager.

It can also be seen from the above formula that the smaller the step angle, the higher the resolution. Therefore, to improve the resolution of the stepper motor, it is necessary to either increase the number of rotor pole pairs (Nr) or adopt a multi-phase method with a larger number of stator phases (P). However, the increase in Nr is limited by mechanical processing constraints, so manufacturing high-resolution stepper motors requires the combined use of both methods. The above information covers the step angles and calculation formulas for stepper motors. If you need to select a suitable stepper motor for your application, you can use the stepper motor selection tool provided by MOONS' (click to access the selection tool) or consult with a product manager.