The Advantages of Capacitive VS Optical Encoders

PID SYSTEM MODIFICATIONS

System optimization and loop time modification are important aspects of motion control. It is often difficult to find the correct change when a system's response needs to be modified due to irregular or unwanted behavior. Either the PID times of the system should be adjusted with timely code review and modification, or the line count (resolution) can be adjusted. The ability to dynamically modify the resolution of the AMT simplifies the process of modifying the system response. To achieve the desired result, the PID control engineer simply adjusts the line counts of the encoder, evaluating the overall response time until the desired result is obtained. Using an optical encoder, this process would require several different versions to be purchased, increasing the overall cost and lengthening the design process.

System optimization and loop time modification are important aspects of motion control. It is often difficult to find the correct change when a system's response needs to be modified due to irregular or unwanted behavior. Either the PID times of the system should be adjusted with timely code review and modification, or the line count (resolution) can be adjusted. The ability to dynamically modify the resolution of the AMT simplifies the process of modifying the system response. To achieve the desired result, the PID control engineer simply adjusts the line counts of the encoder, evaluating the overall response time until the desired result is obtained. Using an optical encoder, this process would require several different versions to be purchased, increasing the overall cost and lengthening the design process. DUST & DIRT

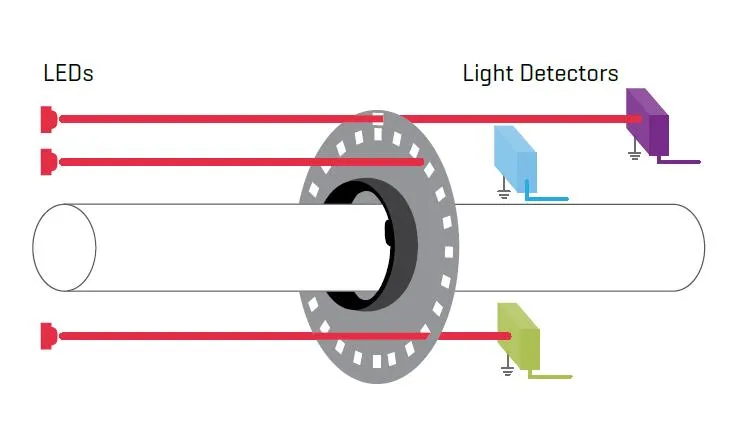

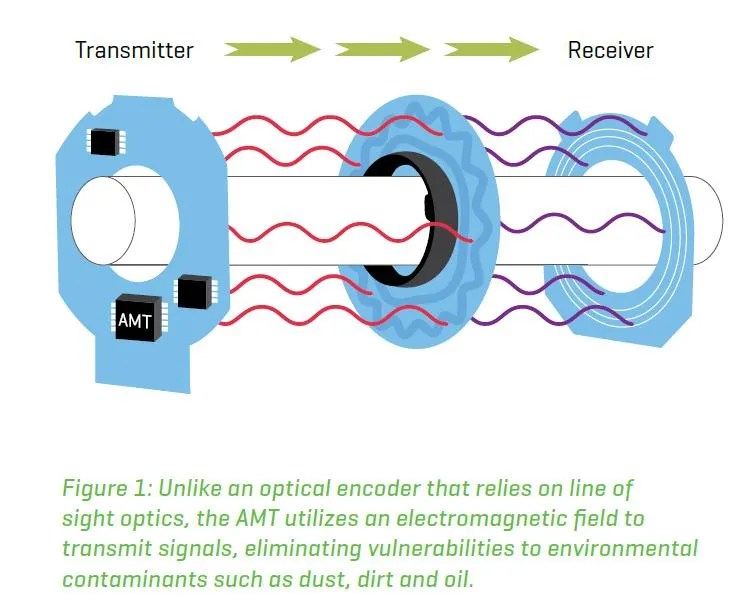

The performance of an optical encoder is influenced by dust, dirt, and other contaminants that accumulate on the optical disk. The LED cannot pass light through the disk to the optical sensor, causing repeatability issues. If an optical disk becomes contaminated, the encoder must be replaced. As an ASIC-driven product, the AMT is not affected by dust and dirt accumulation. The result is a performance that is much more rugged and reliable.

The performance of an optical encoder is influenced by dust, dirt, and other contaminants that accumulate on the optical disk. The LED cannot pass light through the disk to the optical sensor, causing repeatability issues. If an optical disk becomes contaminated, the encoder must be replaced. As an ASIC-driven product, the AMT is not affected by dust and dirt accumulation. The result is a performance that is much more rugged and reliable. TEMPERATURE

In the same way that contaminants can influence the incremental output of an optical disk, temperature fluctuations can also affect the performance of an optical encoder. LEDs, and to some extent optical disks used in optical encoders, are susceptible to thermal stress and have limitations at both ends of the temperature spectrum. The AMT's ASIC technology provides reliable operation across a wider temperature range due to its low sensitivity to heat and cold.VIBRATION

The AMT encoder's ASIC-based construction is far less susceptible to vibration than the fragile glass disk of an optical encoder.

The AMT encoder's ASIC-based construction is far less susceptible to vibration than the fragile glass disk of an optical encoder. LED BURNOUT

LEDs are used in all-optical encoders to generate the light signal that passes through the etched disk and to the optical sensor on the other side. Due to the limited lifespan of the LED, the encoder will eventually fail. By using a semiconductor instead of an LED, the AMT avoids this problem.CURRENT CONSUMPTION

As designers search for ways to meet the market's growing demand for green products, every mA saved becomes increasingly important. An optical modular encoder typically consumes 20 to 50 milliamps of current. AMT offers a range of 6-10 mA, providing a much more efficient solution that is well-suited to mobile and battery-operated devices.INSTALLATION

The AMT was designed to be easy to install. In comparison to optical modular encoders, the AMT is quicker and easier to install, saving OEMs valuable installation time and fall-out expenses caused by misalignment. Certain models, including absolute and commutation models, feature a "One Touch Zero" function that allows the user to flash the zero position to the encoder in a matter of seconds. Installing a commutation optical encoder onto a brushless DC motor (BLDC) can be an iterative and time-consuming process. The optical disk must be physically and precisely rotated to align with the correct motor windings. Once aligned, the assembly must then be checked via back EMF to ensure mounting accuracy. This process can take upwards of 15 minutes per motor. The AMT, being ASIC and MCU based, reduces this time-consuming process to a few mere seconds via the "One Touch Zero" feature saving endless hours and dollars during the manufacturing process.

The AMT was designed to be easy to install. In comparison to optical modular encoders, the AMT is quicker and easier to install, saving OEMs valuable installation time and fall-out expenses caused by misalignment. Certain models, including absolute and commutation models, feature a "One Touch Zero" function that allows the user to flash the zero position to the encoder in a matter of seconds. Installing a commutation optical encoder onto a brushless DC motor (BLDC) can be an iterative and time-consuming process. The optical disk must be physically and precisely rotated to align with the correct motor windings. Once aligned, the assembly must then be checked via back EMF to ensure mounting accuracy. This process can take upwards of 15 minutes per motor. The AMT, being ASIC and MCU based, reduces this time-consuming process to a few mere seconds via the "One Touch Zero" feature saving endless hours and dollars during the manufacturing process. VERSATILITY

The AMT series capacitive encoders offer up to 20 programmable resolution options starting at 48~4,096 PPR. The AMT also comes with multiple sleeve sizes to fit any round back shaft and numerous mounting options in each base. In this way, a customer could use the same encoder sku number for multiple applications, reducing inventory costs and increasing purchasing power. Standard optical encoders come with a single fixed resolution, a single bore diameter, and a limited range of mounting options, which limits their ability to be used in a variety of applications.

The AMT series capacitive encoders offer up to 20 programmable resolution options starting at 48~4,096 PPR. The AMT also comes with multiple sleeve sizes to fit any round back shaft and numerous mounting options in each base. In this way, a customer could use the same encoder sku number for multiple applications, reducing inventory costs and increasing purchasing power. Standard optical encoders come with a single fixed resolution, a single bore diameter, and a limited range of mounting options, which limits their ability to be used in a variety of applications.AMT kits come with 9 color-coded sleeves that will adapt to 9 different motor shaft diameters.

SUMMARY

Encoders are typically used in environments that are not considered ideal. Temperature, vibration, and contaminants pose real threats to incumbent encoder technologies. The AMT series was designed to operate reliably and accurately in challenging designs requiring precise motion feedback. Together with its flexibility and programmability, the AMT is a compelling solution for industrial, robotics, automation, and renewable energy applications.

Encoders are typically used in environments that are not considered ideal. Temperature, vibration, and contaminants pose real threats to incumbent encoder technologies. The AMT series was designed to operate reliably and accurately in challenging designs requiring precise motion feedback. Together with its flexibility and programmability, the AMT is a compelling solution for industrial, robotics, automation, and renewable energy applications.