Why Choose MOONS' integrated motors?

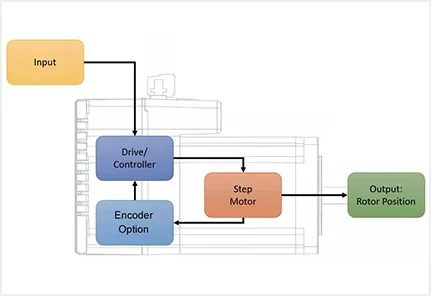

Combining a motor with its controlling electronics eliminates more than just the bulk and cost of extra wiring. MOONS' integrated motors provide improved efficiency, reliability, and electromagnetic compatibility. Additionally, the torque curves for integrated motors eliminate guesswork. By combining the indexer/controller, driver, motor, and feedback, the rest of the system integration is simplified.

The videos are provided by Applied Motion Products, Inc.--a MOONS' company

The videos are provided by Applied Motion Products, Inc.--a MOONS' company TSM integrated stepper VS open-loop stepper

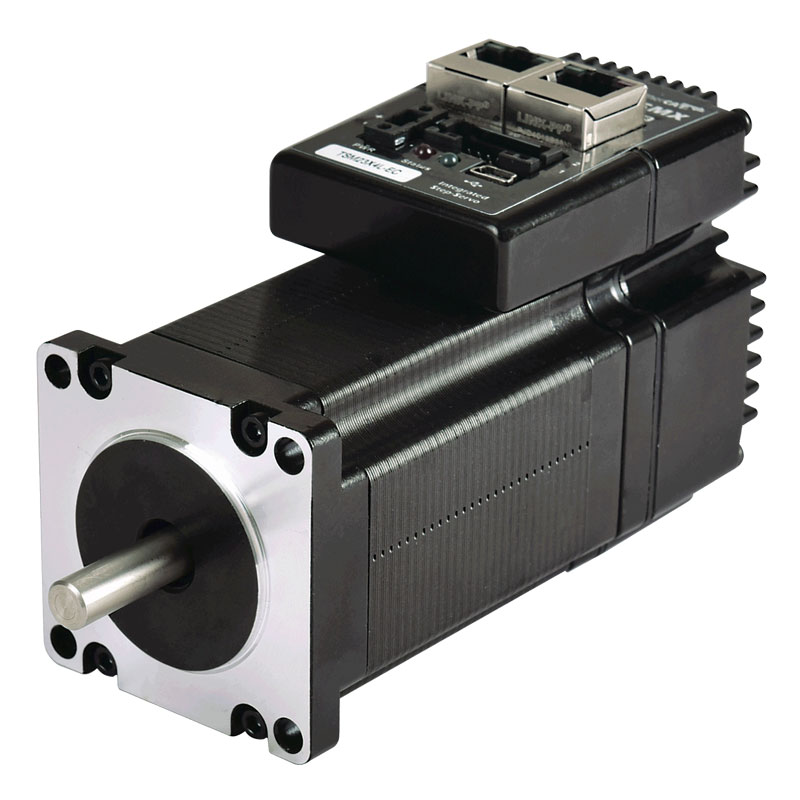

TSM Series Integrated Step-Servo Motor:

With their high torque at low speeds and excellent holding torque characteristics, TSM series integrated motors offer the next evolution in step motor technology. Among these advantages are the ability to produce peak torques up to 50% higher than open loop motors, as well as the ability to run cooler and quieter.

For more details, see the Product Details section on individual product pages.

With their high torque at low speeds and excellent holding torque characteristics, TSM series integrated motors offer the next evolution in step motor technology. Among these advantages are the ability to produce peak torques up to 50% higher than open loop motors, as well as the ability to run cooler and quieter.

For more details, see the Product Details section on individual product pages.

STM Series Integrated Stepper Motor:

The space-saving design of the STM series eliminates wiring and helps you realize better cost-saving over conventional motor and drive solutions. The built-in encoder option allows STM-integrated motors to detect or prevent stalls. Different from the STM-R series, the STM series support multiple control options.

STM-R Series Integrated Stepper Motor:

The STM-R integrated steppers are designed for step & direction (or pulse & direction) control. They are the economical version of the STM series.

The space-saving design of the STM series eliminates wiring and helps you realize better cost-saving over conventional motor and drive solutions. The built-in encoder option allows STM-integrated motors to detect or prevent stalls. Different from the STM-R series, the STM series support multiple control options.

STM-R Series Integrated Stepper Motor:

The STM-R integrated steppers are designed for step & direction (or pulse & direction) control. They are the economical version of the STM series.

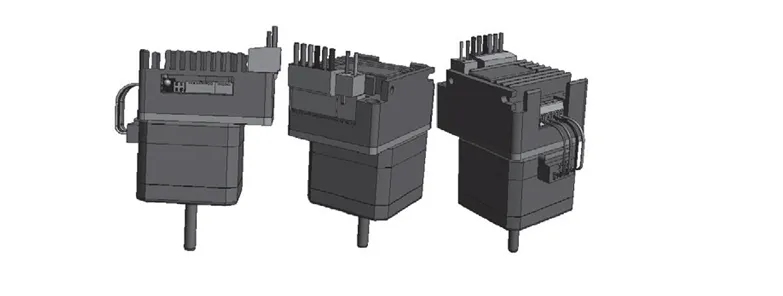

the space-saving design of MOONS' integrated stepper motor

the space-saving design of MOONS' integrated stepper motorThe Questions You May Concern About

What is the advantage of having a built-in encoder for STM series?Expand ∨

The built-in encoder option that is available on our integrated stepper motors can be used for Stall Detection or Stall Prevention. These encoder functions allow for the integrated drive to either fault (in the case of Stall Detection mode) or to slow down the step motor in order to increase the torque output (in the case of Stall Prevention mode) when the encoder feedback indicates that the motor is stalling or near stalling. Stall Detection in combination with Q programming allows for the integrated stepper to perform a hard-stop homing routine, thereby eliminating the need for an external home sensor. The encoder counts may also be used within Q programs or by a 3rd party host controller/HMI over a network connection.

Can I build a integrated stepper motor with the parts from MOONS'? Expand ∨

You need to find the following things:

1. SR3-Mini stepper motor drive

SR3-Mini is one kind of MOONS’ new designed stepper motor drivers. Its special ultra-compact design would allow user to mount anywhere.

2. Incremental Encoder

You could find the encoder made by CUI in our website. This encoder has selectable resolutions up to 2048 PPR.

3. Dual shaft stepper motor

MOONS' Dual shaft stepper motor would be your great choice.

4. Mount Bracker

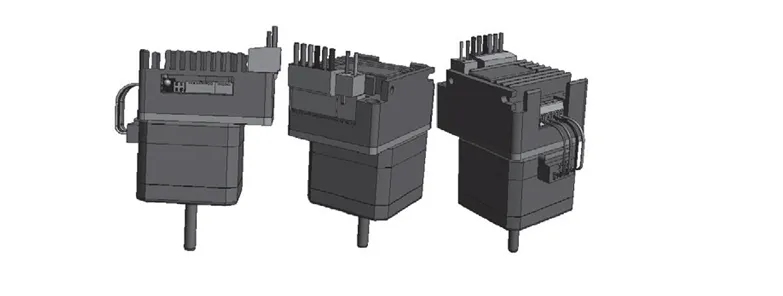

Here is a 3D model for your reference (Stepper motor plus SR3-Mini Stepper Drive):

1. SR3-Mini stepper motor drive

SR3-Mini is one kind of MOONS’ new designed stepper motor drivers. Its special ultra-compact design would allow user to mount anywhere.

2. Incremental Encoder

You could find the encoder made by CUI in our website. This encoder has selectable resolutions up to 2048 PPR.

3. Dual shaft stepper motor

MOONS' Dual shaft stepper motor would be your great choice.

4. Mount Bracker

Here is a 3D model for your reference (Stepper motor plus SR3-Mini Stepper Drive):

In my application, some water may splash on the motor. Is this a suitable application for an integrated motor? Expand ∨

Be sure to use an IP65 rated integrated motor such as SWM24 or TXM24/34 series. These motors are sealed so that water and dust cannot get inside and damage the motor or electronics. They use M12 style cables which are also water tight.

Integrated Servo Motors

The integrated servo motors are used to create decentralized motion control solutions in very compact units.

Integrated Stepper Motors

Integrated drive+motors combine step motor and drive components into one compact unit. These integrated steppers provide a space-saving design that minimizes wiring and reduces costs compared to separate motor and drive components. Available in NEMA 8, 11, 17, 23, 24 and 34 frame size.