MOONS' Launches High-speed Permanent Magnet

Stepper Motor

As printer technology continues to advance rapidly, user demands for speed and torque density in PM permanent magnet stepper motors in printer systems have become increasingly stringent. In response, MOONS' has launched a new series of high-speed permanent magnet stepper motors, featuring models with outer diameters of 25mm, 42mm, and 49mm, as well as a high-speed ultra-thin model at 35mm. This series of motors integrates high-speed and high-power density design concepts, aiming enhanced performance for printing, copying and other office automation applications, fully meeting evolving market demand.

Product Features

High Speed

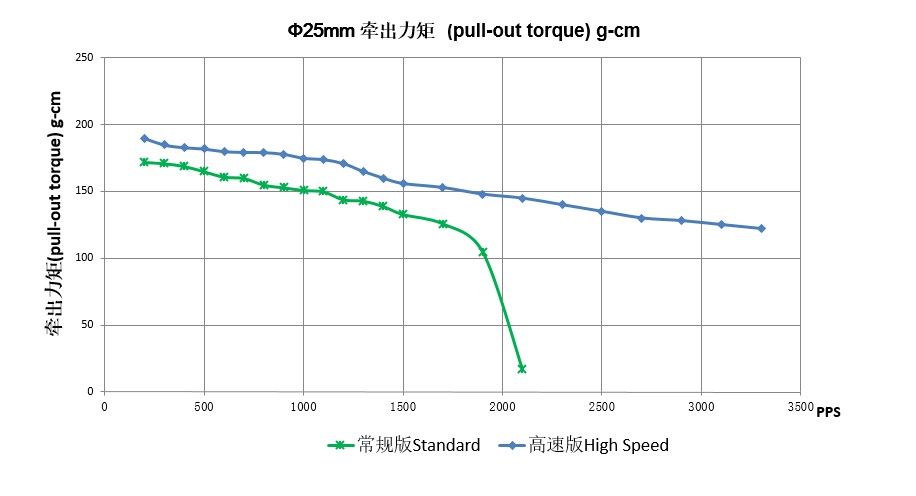

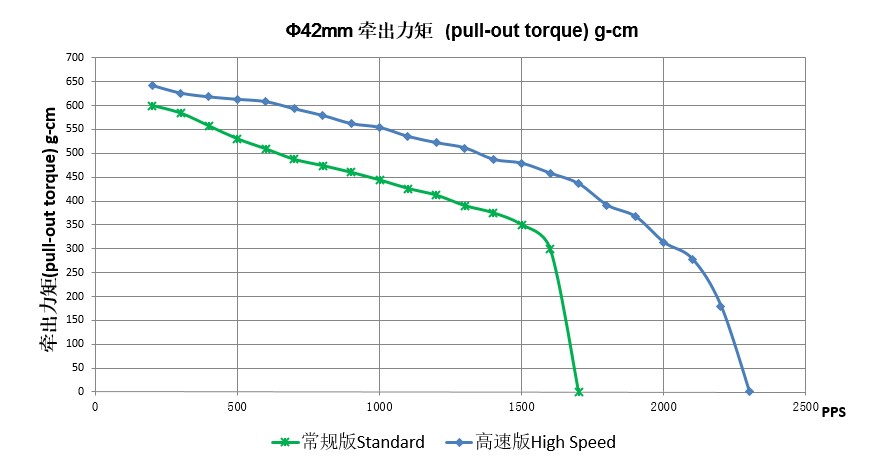

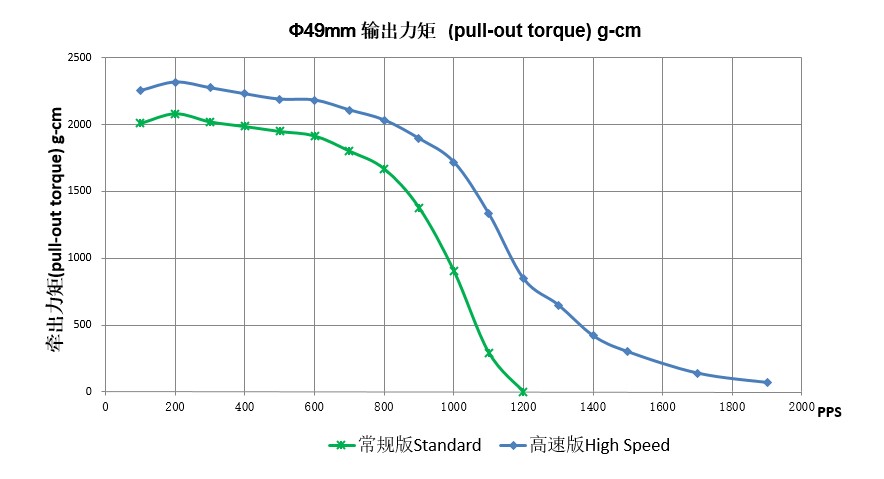

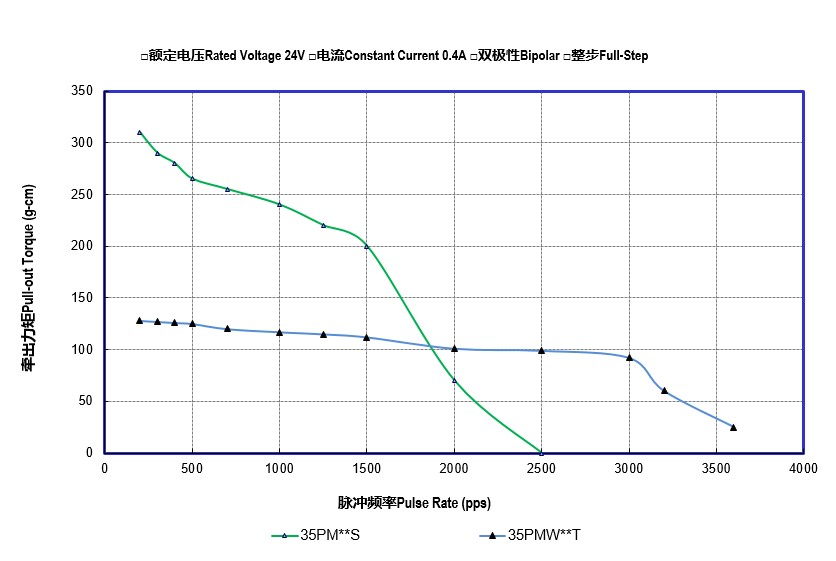

Compared with traditional permanent magnet stepper motors, the high-speed PM motor designed with silicon steel sheets achieves an upper speed limit over 30% under the same driving conditions. This ensures ultra-fast response speeds, making it an ideal fit for high-speed, precision operation requirements.High Power Density

In terms of power density, high-speed PM permanent magnet stepper motors demonstrate a distinct advantage. In the low-speed operation, their output torque is 15% to 20% higher than that of ordinary PM permanent magnet stepper motors. Even in the high-speed ranges, which are challenging for conventional PM motors to manage, high-speed PM permanent magnet stepper motors operate with ease, significantly enhancing efficiency.

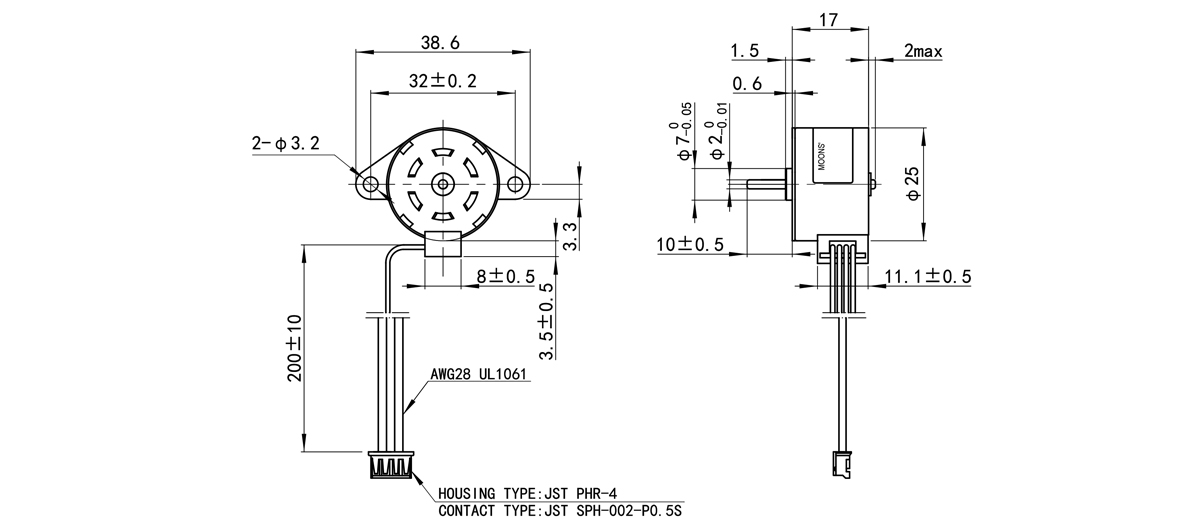

The core advantages of 35PMW096T high-speed ultra-thin motor: Ultra-thin Design: With a thickness of only 8.5mm, this motor is specifically designed for applications requiring compact axial space. High Precision: The minimum step angle can reach 3.75°, and the step angle accuracy is controlled within ±7%, ensuring precise motion control performance. Excellent High-speed Performance: Compared with ordinary PM35**S motors, the maximum speed of 35PMW**T is increase of over 30%, showing significant advantages in high-speed operation.

The core advantages of 35PMW096T high-speed ultra-thin motor: Ultra-thin Design: With a thickness of only 8.5mm, this motor is specifically designed for applications requiring compact axial space. High Precision: The minimum step angle can reach 3.75°, and the step angle accuracy is controlled within ±7%, ensuring precise motion control performance. Excellent High-speed Performance: Compared with ordinary PM35**S motors, the maximum speed of 35PMW**T is increase of over 30%, showing significant advantages in high-speed operation.  MOONS' specializes in high-speed PM permanent magnet stepper motors with outer diameter of 25mm and above. These motors are crafted with high-quality silicon steel sheets and high-performance NdFeB bonded magnets, paired with an optimized magnetic circuit design. This combination allows the motor to maintain high torque even under high-frequency conditions, while offering benefits such as low heat generation, reduced input power consumption and a compact size. This makes it an ideal choice for printers, copiers, scanners, and other office automation equipment.

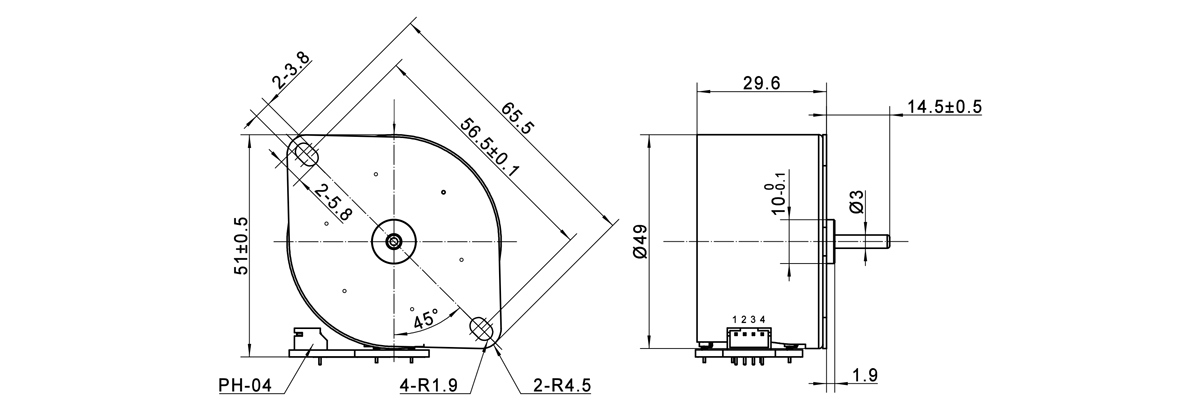

MOONS' specializes in high-speed PM permanent magnet stepper motors with outer diameter of 25mm and above. These motors are crafted with high-quality silicon steel sheets and high-performance NdFeB bonded magnets, paired with an optimized magnetic circuit design. This combination allows the motor to maintain high torque even under high-frequency conditions, while offering benefits such as low heat generation, reduced input power consumption and a compact size. This makes it an ideal choice for printers, copiers, scanners, and other office automation equipment.Motor Specifications and Dimensions

| Model Number | Length (mm) | Step Angle (°) | Rated Current (A) | Holding Torque (mNm) | Resistance (Ω) | Inductance (mH) | Detent Torque (mNm) | Rotor Inertia (gcm²) | Weight (g) |

|---|---|---|---|---|---|---|---|---|---|

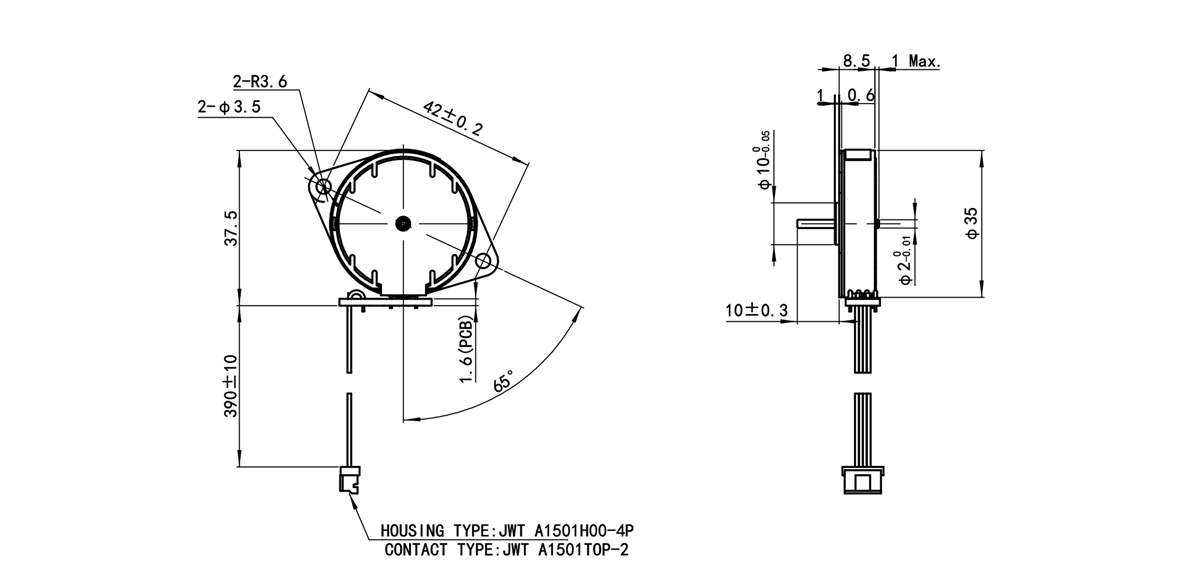

| 25PMW048L8-00801 | 17 | 7.5 | 0.47 | 25 | 8 | 7.5 | 4.5 | 0.85 | 39 |

| 25PMW048L8-01401 | 0.35 | 27 | 14 | 13 | |||||

| 35PMW096T6-00701 | 8.5 | 3.75 | 0.4 | 48 | 7 | 3.5 | 1.8 | 5.1 | 35 |

| 35PMW096T6-02001 | 0.2 | 46 | 20 | 11.3 | |||||

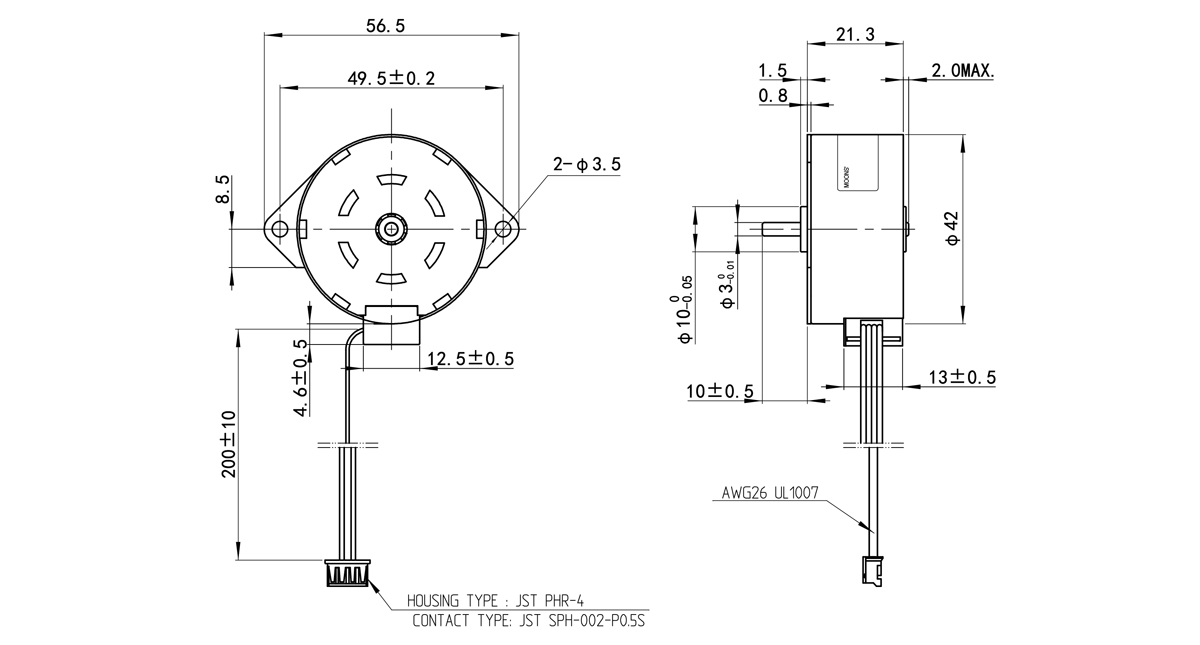

| 42PMW048L8-00302 | 21.3 | 7.5 | 0.85 | 95 | 3.2 | 4.7 | 14 | 11.57 | 120 |

| 42PMW048L8-00703 | 0.55 | 95 | 7 | 11.8 | |||||

| 49PMW048L8-00402 | 29.5 | 7.5 | 1.2 | 260 | 4.5 | 2.8 | 38 | 12 | 160 |

25PMW048L- Φ 25mm, L, 7.5°

35PMW096T- Φ 35mm, T, 3.75°

42PMW048L- Φ 42mm, L, 7.5°

49PMW048L- Φ 49mm, L, 7.5°