STAC6-Q-H Advanced Step Motor Drive for Hazardous Locations

The internationally certified hazardous location stepper drive available • ATEX and IECEx certified for Class I, Zone 2 locations• UL certified for Class 1, Div 2, Group C & D locations

• HazLoc Step Motor Drive

• HazLoc certified for USA, Canada, Europe and Middle East

• Superior performance

• Advanced anti-resonance algorithm

• Torque ripple smoothing

• Microstepping to 51,200 steps/rev

• Stored program for stand-alone operation

• High power output for medium and large size step motors Contact Us for More

Built for Hazardous Locations

Class I hazardous locations are those in which flammable gases, vapors or liquids are, or may be, present in the air in quantities sufficient to produce explosive or ignitable mixtures. Zone 2, also known as Division 2, defines a hazardous location in which flammable gases, vapors or liquids are not likely to occur in normal operation but, if they do occur, will only persist for a short period of time. The STAC6-Q-H stepper drive is certified for Class I, Zone 2 locations (also known as Class I, Division 2 locations). Explosive atmospheres are commonly found in the oil, gas, mining and printing industries, as well as in paint-finishing locations and aircraft hangars. • Certified Category 3 equipment under ATEX Directive 94/9/EC

Superior Performance

Stepper drives from Applied Motion Products are the best in the business. The STAC6 offers best-in-class anti-resonance that ensures optimal performance of the step motor over the widest speed range. The drive is powered by single-phase 120 VAC which generates a nominal 160 volt DC internal bus voltage capable of driving the highest torque NEMA 34 and 42 frame step motors on the market. • Encoder feedback option for enhanced system accuracy using Stall Detection and Stall Prevention

• Designed for use with high quality NEMA 23, 24, 34 and 42 frame step motors

• 7 digital inputs, 3 digital outputs, all optically isolated

• 2 analog inputs, +/-10 volt range

• Designed for use with high quality NEMA 23, 24, 34 and 42 frame step motors

• 7 digital inputs, 3 digital outputs, all optically isolated

• 2 analog inputs, +/-10 volt range

Perfect Solution Set

The HX56-100 stepper motor is specifically designed to be used with the STAC6-Q-H stepper drive, the first ever step motor drive that is internationally certified for use in hazardous locations. The STAC6-Q-H features an advanced anti-resonance algorithm that ensures optimal torque performance from the HX56-100 over a wide speed range. Microstepping ensures smooth, high resolution positioning. HX56-100 Product Features: • ATEX and IECEx certified for Class I, Zone 1 locations

• UL Listed for Class 1, Division 1 locations

• Certified for USA, Canada, Europe and Middle East

• Type 4X and IP66 rated enclosure

• Superior performance when operated with the STAC6-Q-H stepper drive

• UL Listed for Class 1, Division 1 locations

• Certified for USA, Canada, Europe and Middle East

• Type 4X and IP66 rated enclosure

• Superior performance when operated with the STAC6-Q-H stepper drive

Hazardous Locations: Class I hazardous locations are those in which flammable gases, vapors or liquids are, or may be, present in the air in quantities sufficient to produce explosive or ignitable mixtures. Zone 1, also known as Division 1, defines a hazardous location in which flammable gases, vapors or liquids exist all of the time or some of the time under normal operating conditions. The HX56-100 stepper motor is certified for Class I, Zone 1 locations (also known as Class I, Division 1 locations). Explosive atmospheres are commonly found in the oil, gas, mining and printing industries, as well as in paint-finishing locations and aircraft hangars.

Specification

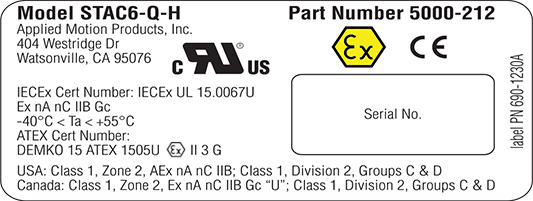

Model Number: STAC6-Q-H

| Part Number | Supply Voltage | Input Power | Output Power | Control Modes |

| 5000-212 | 94-135 VAC, 50/60 Hz, single-phase | 120 Vac, 1 Phase, 1.67 A (rms) | 120 Vdc, 1 phase, 4.24 A (rms), Continuous Duty Rating | Streaming Commands, Analog Positioning, Encoder Following, Q Programming |

| Output Current | Communication Ports | Encoder Feedback | Step Resolution | Idle Current Reduction | Setup Method | Digital Inputs |

| 0.5-6.0 A/phase, peak-of-sine | RS-232, RS-485 | Yes | Full, Half, Microstepping, Microstep Emulation | 0-100% | Software setup | 7 |

| Digital Outputs | Analog Inputs | Dimensions | Weight | Ambient Temperature Range | Ambient Humidity |

| 3 | 1 differential or 2 single-ended | 6.35 x 4.66 x 2.31 inches | 32 oz. | -40 to +55 °C (-40 to +131 °F) | 90% max, non-condensing |

| Status LEDs | Circuit Protection |

| 1 red, 1 green | Short circuit, Over-voltage, Under-voltage, Over-temp |

下载

STAC6-Q-H

Hardware Manual: STAC6-Q-H Hardware Manual Download Quick Setup Guide: STAC6-Q-H Quick Setup Guide Download Click here to download the ATEX Certificate Click here to download the IECEx certificate (search Name: applied motion) Click here to download the UL certificateHX56-100

3D Drawings: PDF/STEP Download