A New Breakthrough in Multi-turn Absolute Encoder with Small Size - W16

In precision control applications, space constraints and high accuracy demands frequently challenge engineers. MOONS' newly introduced W16 series, a compact multi-turn absolute encoder with a Ø16mm design, is perfectly suited to address these issues. The small stature of the W16 encoder makes it an ideal solution for numerous applications requiring both compactness and precision control. Additionally, this encoder offers rapid response times and high operational efficiency, along with a power-off memory feature, ensuring stable and reliable absolute position feedback with superior performance and exacting control. The W16 series multi-turn absolute encoder, introduced by MOONS', is compatible with slotless hollow cup motors of Ø16mm or larger. This product, following the launch of the P22 series in 2022, epitomizes the pinnacle of professional dedication and excellence, embodying both a broad and meticulous design philosophy. With an outer diameter of just 16mm, the W16 series encoders are significantly more compact compared to the P22 (Ø22mm) series. This reduction in size makes them particularly suited for applications where space is at a premium, facilitating designs that require miniaturization.

1. Product Features

High Integration • The W16's Ø16mm compact design allows for seamless integration into existing systems. This small encoder is particularly advantageous in systems where space is limited and the integration of multiple sensors and electronic components is essential. Power off Memory • The encoder provides absolute position information, eliminating the need for zeroing at each startup. Multi-Rotation Recording • The W16 series encoder is capable of recording multiple rotations, making it ideal for applications requiring long-distance rotational measurements. This encoder features a battery-powered design, reducing reliance on external power sources and extending its lifespan. As a result, it lowers maintenance and operational costs, particularly beneficial in applications demanding prolonged operation. Simplified Mechanisms • The encoder eliminates the need for additional counting and resetting mechanisms, simplifying both system design and programming. This not only streamlines operations but also significantly reduces the risk of errors. Efficient Positioning • In applications that involve frequent starting and stopping, the encoder delivers instant absolute position information. This feature significantly reduces the time needed for system repositioning, thereby enhancing overall work efficiency.

2. Specifications

| Encoder Parameter | ||

|---|---|---|

| 1 | Working principle | Magnetic |

| 2 | Signal record type | Absolute Multi-turn |

| 3 | Counts per turn(bit) | 8192 |

| 4 | Single-turn resolution | 13 Bits |

| 5 | Number of revolutions | 16 Bits(65536) |

| 6 | Clock rate | 0.08-10MHz |

| 7 | Signal protocol | BiSS C |

| 8 | Output code | Binary |

The W16 series multi-turn absolute encoder offers precise and reliable absolute position feedback. It features a single-turn resolution of 13 bits, a multi-turn capacity of 16 bits, and up to 8192 steps per turn.

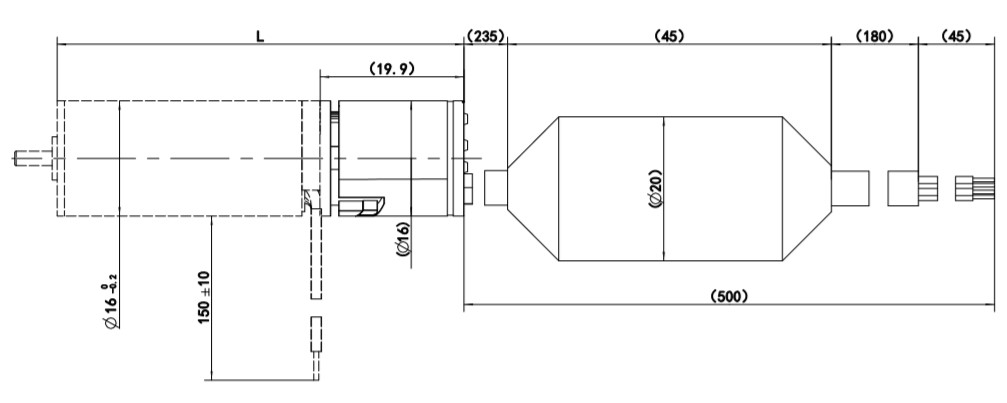

3. Dimensions

4. Application Features

The W16 multi-turn absolute encoder boasts a notable advantage with its Ø16mm compact design, making it ideal for installation in space-constrained devices and systems such as micro robots, medical equipment, and portable instruments. This small-scale design allows users to maximize internal installation space, enabling designers to incorporate more features within limited spaces, thus optimizing the internal layout of devices. Furthermore, the W16 series encoder is lightweight, which is particularly beneficial for applications aiming to reduce the overall weight of devices, such as mobile robots and handheld devices. The lightweight design not only enhances device portability but also reduces overall energy consumption. Owing to its small size, light weight, and low inertia, the W16 series encoder provides a faster response in high-dynamic applications and is well-suited for uses demanding high precision and rapid position feedback. ♦ Precise and Compact, Flexible Installation Utilizing advanced design and manufacturing techniques, our encoders achieve an exceptionally compact form while maintaining high precision. Their flexible installation options allow for easy integration into a variety of complex and constrained devices, significantly broadening their range of applications. ♦ Energy Saving, Environmental Protection, Long Life With their low power consumption design, our W16 series encoders not only promote energy efficiency and environmental sustainability but also extend service life. This reduction in maintenance costs and downtime results in higher economic benefits for your system. ♦ Wide Range of Applications, Unlimited Possibilities Our W16 series encoders excel across various sectors, from smart manufacturing and industrial automation to medical equipment and precision instruments. Regardless of the complexity of your project, we are committed to delivering customized solutions that fulfill all your requirements.

MOONS' boasts a diverse range of encoder products that can be flexibly paired with hollow cup and slotless motors ranging from φ8 to φ30. Additionally, we offer customers a variety of options in both type and resolution, including magnetic and optical encoders, and incremental or absolute formats, to fully satisfy all demands for precise control and accurate position feedback. As you pursue precision and efficiency, MOONS' encoder product line will prove to be an essential solution for your needs.

※ Due to subsequent product upgrades, product performance/specifications are subject to change without prior notice.