MOONS' Unveils Unrivalled Super Large Hollow Shaft Motors for Diverse Applications

MOONS' Industries, a global leader in motion control solutions, announce its cutting-edge line of super large hollow shaft motors. Designed to provide exceptional performance, flexibility, and value across a wide range of applications, these motors are set to revolutionise the way machine builders and system integrators approach their projects.

MOONS' super large hollow shaft motors offer a unique combination of high torque output and large bore diameters, making them the ideal choice for applications requiring both power and versatility. With output torque levels that are higher than our competitors and nearly matching those of our own solid shaft motors, MOONS' hollow shaft motors outperform competitors by delivering at least twice the torque for the same frame size and aperture.

Our customers have been seeking a motion control solution that can seamlessly integrate with their existing systems while providing the power and flexibility they need to tackle even the most challenging applications. Our super large hollow shaft motors are the answer, offering unmatched performance and value across industries.

The large bore diameters of MOONS' hollow shaft motors open up a world of design possibilities, allowing for the integration of linear transmission shafts, cables, air flow, liquids, or even beams directly through the centre of the motor. This innovative design approach simplifies system architecture, reduces component count, and enables the creation of compact, multifunctional units that streamline machine design and assembly processes.

MOONS' super large hollow shaft motors are particularly well-suited for applications in robotics, semiconductor manufacturing, industrial automation, and security systems. When paired with a harmonic gearbox, these hollow shaft motors provide the high torque, precise positioning, and efficient operation required to excel in these demanding environments.

As with all MOONS' products, these super large hollow shaft motors are backed by the company's global support network and application expertise. MOONS' experienced engineers work closely with customers to develop tailored motion control solutions that maximise performance and reliability while minimising the total cost of ownership.

At MOONS', we pride ourselves on being a customer-centric organisation that delivers value at every stage of the project lifecycle. Our super large hollow shaft motors are just the latest example of our commitment to providing innovative, high-performance solutions that help our customers achieve their goals.

For more information about MOONS' super large hollow shaft motors and how they can benefit your application, please visit: https://www.moonsindustries.com/series/hollow-shaft-hybrid-stepper-motors-b020114

MOONS' offers a diverse range of motor products, each specifically engineered for various applications, as detailed below:

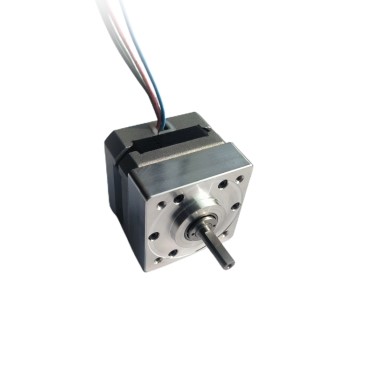

Hybrid Stepper Motors with Gearbox

Stepper motor with planetary gearbox, multiple step angles available: 0.9°, 1.8°, 3.6°, multiple reduction ratios available: 5, 10, 25

Advantages:

● High torque, high precision

● High power density

● Can match large inertia load

● Flat Type, low noise, low vibration

Hybrid Stepper Motors with Encoder

Stepper motor with optical or magnetic encoder, resolution 1000 lines or 1024 lines, high-precision anti-interference, suitable for dust, dirt, oil stain environment, and realizes simple closed-loop control.

Advantages:

● High precision: 1000 or 1024 lines

● Anti-interference: ABZ differential optical or magnetic encoder

● High torque, high efficiency

● Compatible products: gearbox, flexible coupling, damper

Encapsulated Hybrid Stepper Motors

Encapsulation technology from MOONS' offers many advantages. Ideal for security cameras, low temperature rise, 35% more torque, quieter & smoother, more load & longer life.

Advantages:

● Smoother

● High precision

● Small size

● High torque

Anti-corrosion Hybrid Stepper Motors

Protective coating on the surface by special processing technology, can effectively prevent rust and corrosion. The coatings that were previously used were not rugged enough to protect the soft-iron magnetic and metallic materials inside a step motor over its design life. The new technique applies the coating to every surface and structure inside and outside the motor, including the rotor, stator, and housing. It essentially coats every one of the surfaces that could potentially rust, such as steel and aluminium. The material selections and coatings are tailored for each motor component. For example, the permanent magnets, aluminium endbells, and steel laminations use coatings, and upgraded base materials as needed to protect the parts from corrosion, while maintaining motor performance.

Advantages:

● Corrosion resistant coating inside and outside

● Withstand salt spray test for long durations

● Widely used in aircraft, ships, automobiles, antennas, solar equipment, etc.

● Available options for Wire Harness

Recommended Articles:

MOONS' Unveils Revolutionary PTX05 HPM Nano Step Motor

NEW AC STEPPER DRIVES PROVIDE BOOST TO INDUSTRIAL AUTOMATION

New Ø19mm Slotless Motor to Enhance Handheld Device Performance