* Free shipping to North America and most of Europe for orders of $100 or more

- Home

- Stepper Motors

- Hybrid Stepper Motors

- Encapsulated Hybrid Stepper Motors

- CSE14HR Encapsulated Hybrid Stepper Motors

ID CSE14HR Encapsulated Hybrid Stepper Motors

Encapsulated stepper motor, Smoother, High precision, Small size, High torque, Step Angle: 1.8°, NEMA14, Φ36mm

● Smoother

● High precision

● Small size

● High torque

● High precision

● Small size

● High torque

Brand Name: MOONS'

Payment Methods

Buyer Protection:

Buyer Protection:

- current tab: Description & Feature

- Data Sheet

- Online Ordering

- Dimension

- Downloads

- Recommended Options

- Delivery & Packaging

Encapsulated stepper motor introduction

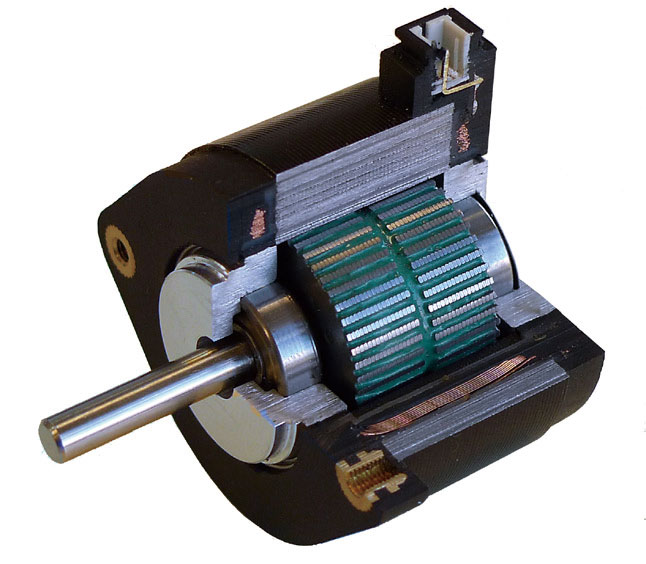

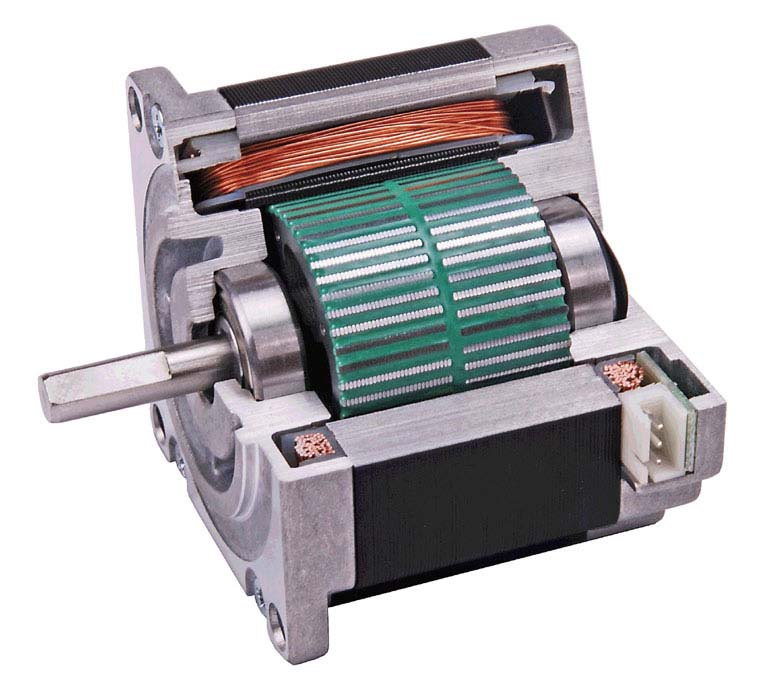

Encapsulated stepper motors consist of a winding and motor structure that are integrated through encapsulation molding. When compared with traditional stepping motors, encapsulated stepping motors perform better in terms of torque, size, weight, reliability, consistency, stability, running precision, noise, and other aspects.

Excellent heat conduction system: The space between the stator enameled wires, frame, iron cores, and installation end faces is filled with plastic that has excellent thermal conductivity, reducing the thermal resistance of the motor heat dissipation channel, improving the heat dissipation performance of the motor winding, as well as improving the motor's reliability.

Excellent heat conduction system: The space between the stator enameled wires, frame, iron cores, and installation end faces is filled with plastic that has excellent thermal conductivity, reducing the thermal resistance of the motor heat dissipation channel, improving the heat dissipation performance of the motor winding, as well as improving the motor's reliability.Excellent insulation system: The motor winding and the installation end face are filled with plastic, which provides good thermal conductivity and reduces the distance between the winding and the end bell. In addition to its smaller axial dimension, the motor's torque volume density and torque mass density are improved as well.

Encapsulated stepper motor features

Low temperature rise, High torque

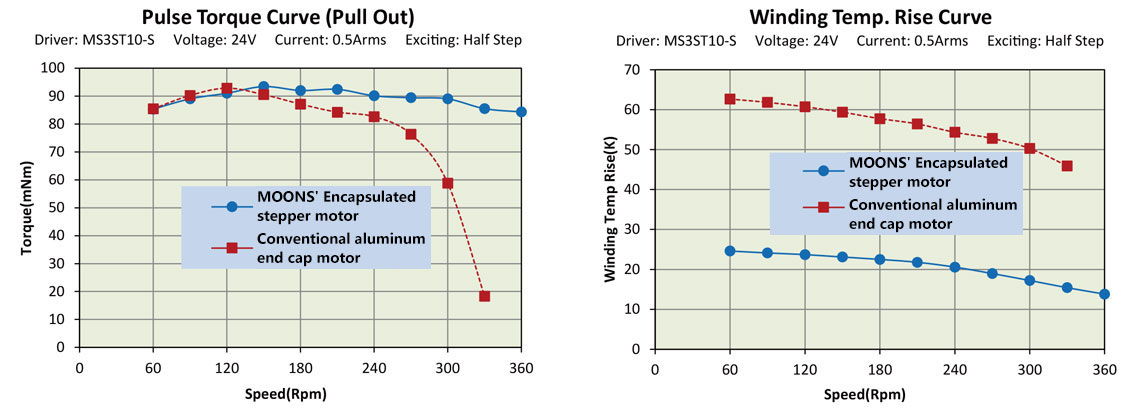

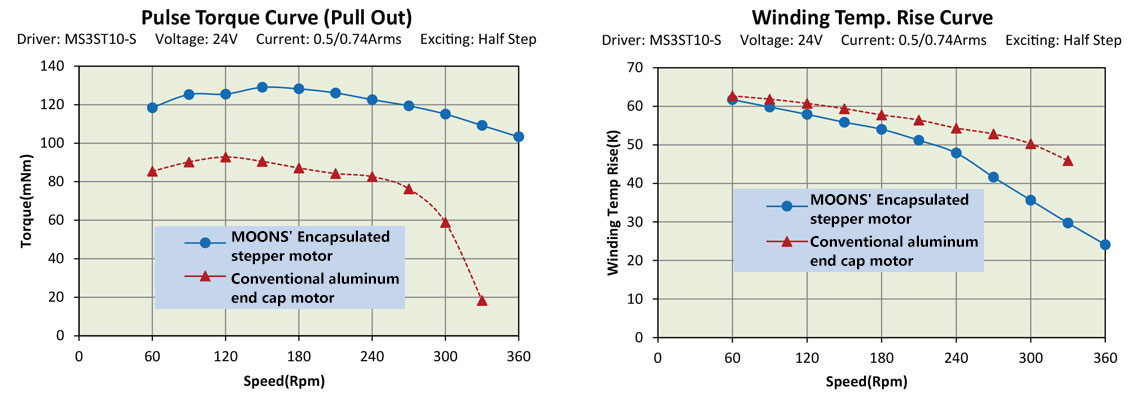

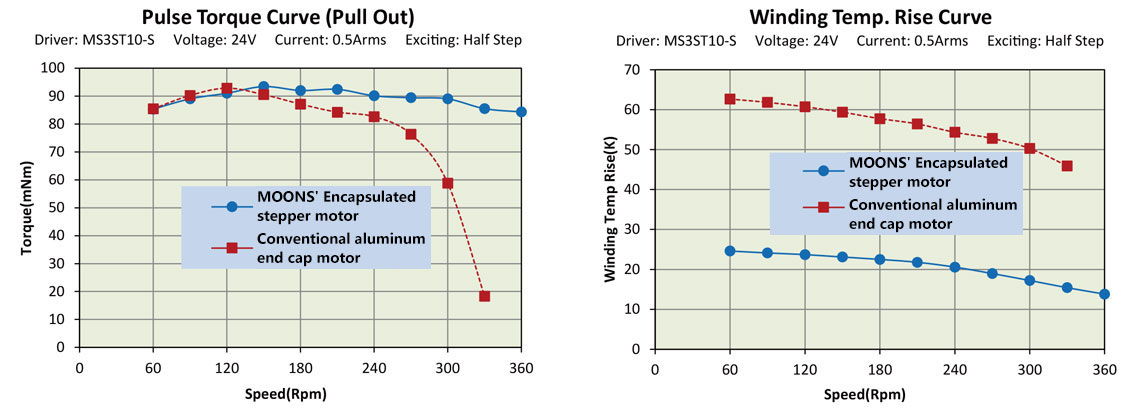

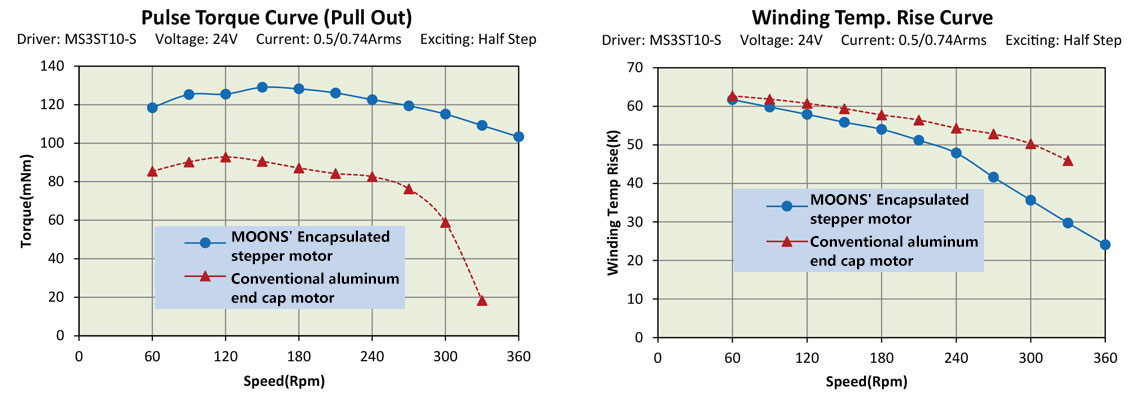

As two encapsulated motors and two aluminum end cap motors with the same size and thickness are fed the same current, the output torque of the two motors is approximately equal, and the temperature rise of the windings of the encapsulated motor is lower (the temperature rise is reduced by more than 30K). Continually increase the winding current for the encapsulated molding motor. When the temperature rise of the motor winding is approximately the same, the output torque of the encapsulated molding motor is greater (the torque at maximum speed is increased by 50%).

Continually increase the winding current for the encapsulated molding motor. When the temperature rise of the motor winding is approximately the same, the output torque of the encapsulated molding motor is greater (the torque at maximum speed is increased by 50%).  In the same way, if the same temperature rise and torque are maintained, the encapsulated motor can be designed to be thinner, lighter and smaller.

In the same way, if the same temperature rise and torque are maintained, the encapsulated motor can be designed to be thinner, lighter and smaller.

As two encapsulated motors and two aluminum end cap motors with the same size and thickness are fed the same current, the output torque of the two motors is approximately equal, and the temperature rise of the windings of the encapsulated motor is lower (the temperature rise is reduced by more than 30K).

Continually increase the winding current for the encapsulated molding motor. When the temperature rise of the motor winding is approximately the same, the output torque of the encapsulated molding motor is greater (the torque at maximum speed is increased by 50%).

Continually increase the winding current for the encapsulated molding motor. When the temperature rise of the motor winding is approximately the same, the output torque of the encapsulated molding motor is greater (the torque at maximum speed is increased by 50%).  In the same way, if the same temperature rise and torque are maintained, the encapsulated motor can be designed to be thinner, lighter and smaller.

In the same way, if the same temperature rise and torque are maintained, the encapsulated motor can be designed to be thinner, lighter and smaller. Small size (High Torque Volume Density)

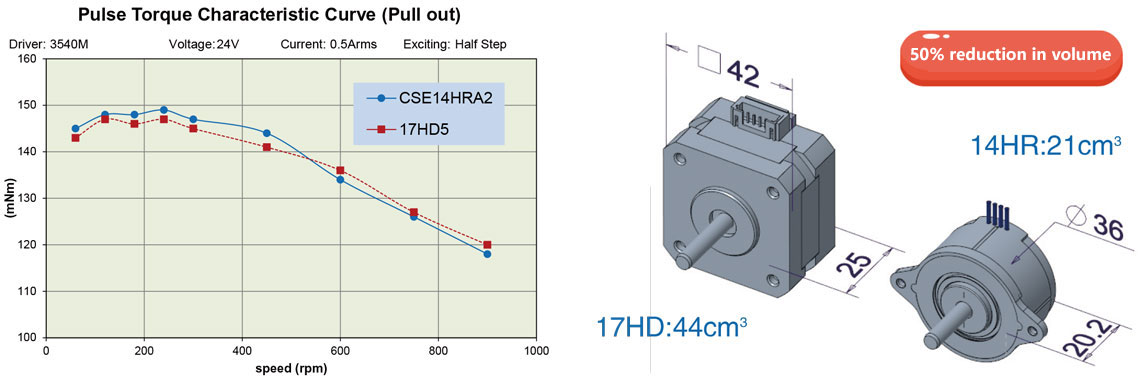

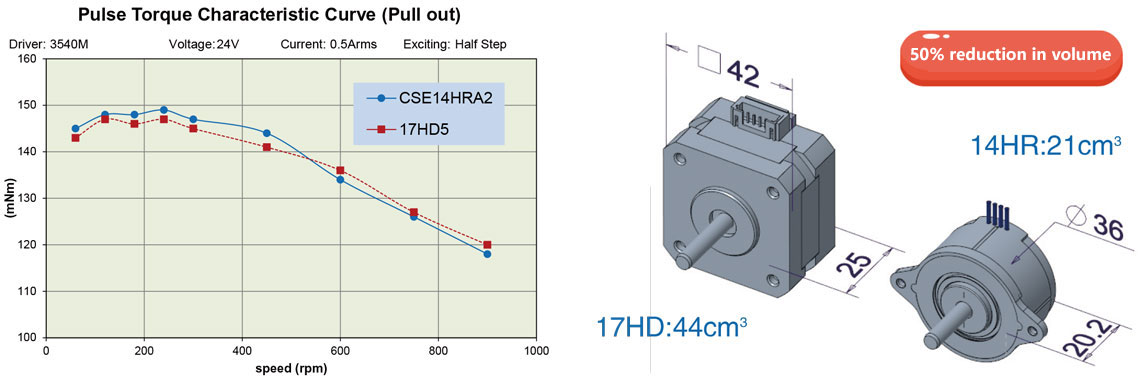

Compared with the MS17HD5 series aluminum end cap motor, the encapsulated molding motor CSE14HR has a 50% reduction in volume (assuming a slightly higher motor operating torque and a similar temperature rise). The encapsulated motor has a high torque volume density and is thinner and more compact, so it has been widely used in optical equipment and PTZ applications.

Compared with the MS17HD5 series aluminum end cap motor, the encapsulated molding motor CSE14HR has a 50% reduction in volume (assuming a slightly higher motor operating torque and a similar temperature rise). The encapsulated motor has a high torque volume density and is thinner and more compact, so it has been widely used in optical equipment and PTZ applications.

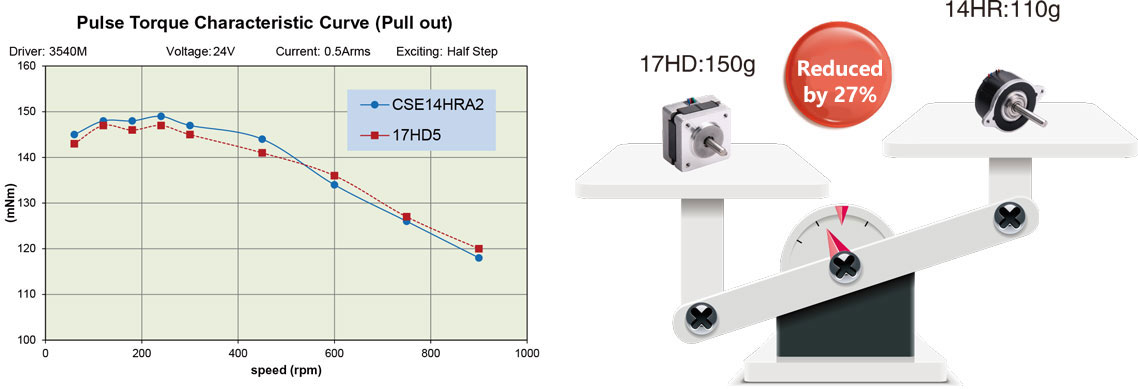

Lightweight (High Torque Mass Density)

In comparison to the MS17HD5 aluminum end cap motor, the encapsulated motor CSE14HR has a weight reduction of approximately 27% (when the motor operating torque is slightly higher and the temperature rise is the same). As a result of the high torque mass density of encapsulated motors, the motor's weight has decreased significantly, and encapsulated motors are increasingly popular with customers in optical equipment, gimbals, and 3D printing applications.

In comparison to the MS17HD5 aluminum end cap motor, the encapsulated motor CSE14HR has a weight reduction of approximately 27% (when the motor operating torque is slightly higher and the temperature rise is the same). As a result of the high torque mass density of encapsulated motors, the motor's weight has decreased significantly, and encapsulated motors are increasingly popular with customers in optical equipment, gimbals, and 3D printing applications.

14HR series: 2-phase 1.8°

| Phase | 2 |

| Steps/ Revolution | 200 |

| Step Angle | 1.8° |

| Step Accuracy | ±5% |

| Axial Load(20,000 hours at 1000RPM ) | 25 N (5.6 Lbs.) Push |

| 65 N (15 Lbs.) Pull | |

| Radial Load(20,000 hours at 1000RPM ) | 30 N (6.5 Lbs.)At Output Shaft End |

| IP Rating | 40 |

| Approvals | RoHS |

| Operating Temp. | -20°C to +50°C |

| Insulation Class | B, 130°C |

| Insulation Resistance | 100 MegOhms |

CSE14HR- 4 Lead Bi-Polar

| Length (mm) | Model Number | Connect | Rated Current | Holding Torque | Winding | Rotor Inertia | Motor Weight | |||||

| Single Shaft | P=Plug L=Leads | Amps (mounted) | Nm Typ. | oz-in Typ. | Ohms @20℃ | mH Typ. | g.cm² | oz-in² | kg | Lbs | ||

| 12.8mm (0.5 in.) | CSE14HRA0L4040 | L | 0.4 | 0.065 | 9.2 | 8.2 | 7.4 | 4 | 0.022 | 0.05 | 0.11 | |

| ^ | CSE14HRA0L4100 | L | 1 | 0.065 | 9.2 | 1.3 | 1.2 | |||||

| 17.4mm (0.69 in.) | CSE14HRA1L4040 | L | 0.4 | 0.115 | 16.3 | 12.5 | 12.5 | 9 | 0.049 | 0.085 | 0.19 | |

| ^ | CSE14HRA1L4100 | L | 1 | 0.115 | 16.3 | 2.1 | 2 | |||||

| 20.2mm (0.8 in.) | CSE14HRA2L4040 | L | 0.4 | 0.19 | 26.9 | 21 | 24 | 11 | 0.060 | 0.11 | 0.24 | |

| ^ | CSE14HRA2L4100 | L | 1 | 0.19 | 26.9 | 3.3 | 4 | |||||

| 31.4mm (1.24 in.) | CSE14HRA3L4040 | L | 0.4 | 0.29 | 41.1 | 20 | 31.3 | 23 | 0.126 | 0.17 | 0.37 | |

| ^ | CSE14HRA3L4100 | L | 1 | 0.29 | 41.1 | 3.4 | 5.3 | |||||

| ^: Recommended model | ||||||||||||

PSE14HR- PowerPlus-4 Lead Bi-Polar

| Length (mm) | Model Number | Connect | Rated Current | Holding Torque | Winding | Rotor Inertia | Motor Weight | |||||

| Single Shaft | P=Plug L=Leads | Amps (mounted) | Nm Typ. | oz-in Typ. | Ohms @20℃ | mH Typ. | g.cm² | oz-in² | kg | Lbs | ||

| 12.8mm (0.5 in.) | PSE14HRA0L4040 | L | 0.4 | 0.088 | 12.4 | 8.2 | 5.9 | 4 | 0.022 | 0.053 | 0.12 | |

| ^ | PSE14HRA0L4100 | L | 1 | 0.088 | 12.4 | 1.3 | 1.0 | |||||

| 17.4mm (0.69 in.) | PSE14HRA1L4040 | L | 0.4 | 0.15 | 21.2 | 12.5 | 11.0 | 9 | 0.049 | 0.089 | 0.20 | |

| ^ | PSE14HRA1L4100 | L | 1 | 0.15 | 21.2 | 2.1 | 1.7 | |||||

| 20.2mm (0.8 in.) | PSE14HRA2L4040 | L | 0.4 | 0.23 | 32.6 | 21 | 20.5 | 11 | 0.060 | 0.12 | 0.25 | |

| ^ | PSE14HRA2L4100 | L | 1 | 0.23 | 32.6 | 3.3 | 3.3 | |||||

| 31.4mm (1.24 in.) | PSE14HRA3L4040 | L | 0.4 | 0.42 | 59.5 | 20 | 24.8 | 23 | 0.126 | 0.18 | 0.39 | |

| ^ | PSE14HRA3L4100 | L | 1 | 0.42 | 59.5 | 3.4 | 4.2 | |||||

| ^: Recommended model | ||||||||||||

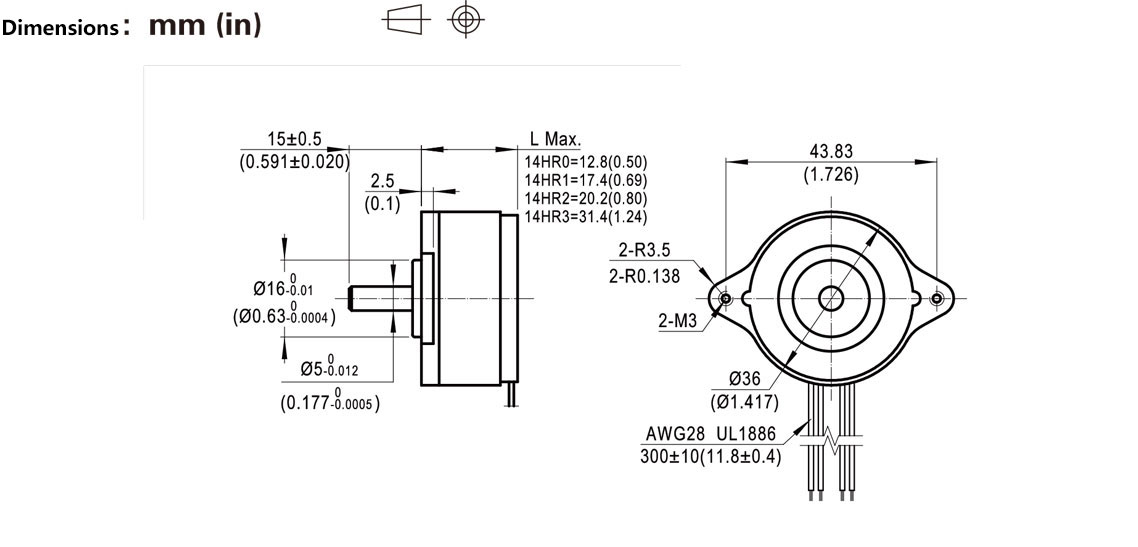

Dimensions

2D Drawings

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| CSE14HRA1L4100.pdf | 1421 | ||

| CSE14HRA2L4100.pdf | 1433 | ||

| PSE14HRA1L4100.pdf | 1405 | ||

| PSE14HRA0L4100.pdf | 1404 | ||

| PSE14HRA3L4100.pdf | 1508 | ||

| CSE14HRA0L4040.pdf | 1419 | ||

| PSE14HRA2L4100.pdf | 1438 | ||

| CSE14HRA3L4100.pdf | 1503 | ||

| CSE14HRA0L4100.pdf | 1396 | ||

| PSE14HRA3L4040.pdf | 1419 | ||

| CSE14HRA1L4040.pdf | 1407 | ||

| PSE14HRA1L4040.pdf | 1403 | ||

| CSE14HRA3L4040.pdf | 1427 | ||

| PSE14HRA0L4040.pdf | 1404 | ||

| CSE14HRA2L4040.pdf | 1440 | ||

| PSE14HRA2L4040.pdf | 1409 |

3D Model

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| CSE14HRA1L4100.stp | STEP | 412 | |

| CSE14HRA2L4100.stp | STEP | 641 | |

| CSE14HRA0L4040.stp | STEP | 496 | |

| PSE14HRA1L4100.stp | STEP | 412 | |

| PSE14HRA0L4100.stp | STEP | 496 | |

| PSE14HRA2L4100.stp | STEP | 641 | |

| CSE14HRA2L4040.stp | STEP | 641 | |

| CSE14HRA0L4100.stp | STEP | 496 | |

| CSE14HRA1L4040.stp | STEP | 412 | |

| PSE14HRA3L4040.stp | STEP | 519 | |

| PSE14HRA0L4040.stp | STEP | 496 | |

| PSE14HRA3L4100.stp | STEP | 519 | |

| PSE14HRA2L4040.stp | STEP | 641 | |

| PSE14HRA1L4040.stp | STEP | 412 | |

| CSE14HRA3L4040.stp | STEP | 519 | |

| CSE14HRA3L4100.stp | STEP | 519 |

Catalog

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| Catalog.pdf | 8551 |

Filter By Product Type

All ProductsDriver

Delivery & Packaging

Ensure your ordered products are always safely packaged from easy click to fast delivery to your handsProfessional Product Label

Considering all possible harsh application environments, MOONS' specially designed labels for each product, which pass water-resistance test, durability rub test, high temperature resistance and corrosion resistance tests.Besides, our product labels are attached with QR code linking to product details, which is convenient for clients to view the detail product page with their mobile phones.

Note: This label design is suitable for products of stepper motor.

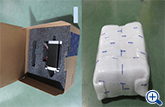

(Professional packing box and unique appearance design)

(Single item packed with EPE)

(Multi-products packed with another box)

Safely Packaging

In order to ensure your shipments withstand the long trip and arrive safely and intact, MOONS' specially designed Individual package to pass the drop test with its stable structure.Besides,the package is made from recyclable materials, providing you with professional safety delivery.

Whether just single item or multi-products the clients buy, all products are packed twice to avoid the damage further.

Shipping Visualization

For each case, products are carefully packed by experienced warehouse staff and the key processes are recorded by photos, which are then posted on our website, so that clients could clearly know the packing process and logistics status after placing order.

(Product in the box)

(Add the invoice)

(Label the commodity)

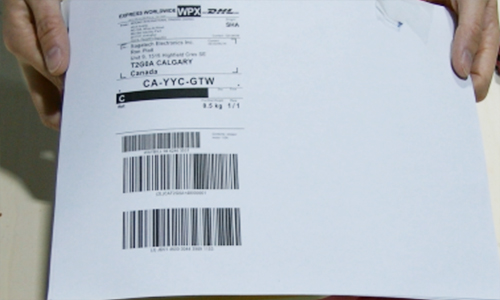

(The logistics waybill attached)

Fast Delivery

Fast Cross-Border DeliveryMOONS' chooses DHL as our main international express shipping partner. As the world's leading logistics specialist, DHL provides our customers with fast and professional inter- national door-to-door delivery service.

Estimated Delivery Time: e.g. China-USA major cities 3 business days.

Professional

Warehouse Management

Free Exchange

Free Exchange