* Free shipping to North America and most of Europe for orders of $100 or more

ID M54S Series Universal AC Input Servo Drives

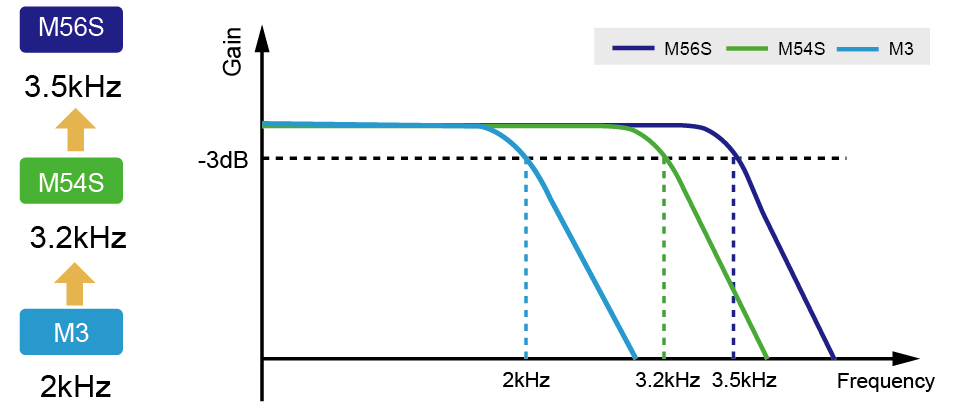

M54S series is a new generation of universal 220V AC input servo system, the power range is from 50W to 1000W. The drive incorporates the concept of high power density and compact design. It adopts advanced motion control algorithms, coupled with a 21-bit high precision encoder motor, the velocity loop bandwidth is up to 3.2KHz. Efficient automatically adjusts the loop gain, superior vibration suppression and external disturbance compensation performance. All the series drive has built-in dynamic braking module, it supports the control mode of position, velocity, torque as well as Q programming. EtherCAT, CANopen, Modbus/RUT industrial fieldbus are available.

● 220V AC servo system

● Built-in dynamic braking function

● Power range of 50W to 1000W

● Velocity loop bandwidth up to 3.2KHz

● High power density and compact design

● Better vibration suppression and external disturbance compensation performance

● Efficient auto-tuning

● CE certification

● Supports EtherCAT, CANopen, Modbus/RTU field bus

● Built-in dynamic braking function

● Power range of 50W to 1000W

● Velocity loop bandwidth up to 3.2KHz

● High power density and compact design

● Better vibration suppression and external disturbance compensation performance

● Efficient auto-tuning

● CE certification

● Supports EtherCAT, CANopen, Modbus/RTU field bus

Brand Name: MOONS'

Payment Methods

Buyer Protection:

Buyer Protection:

- current tab: Description & Feature

- Data Sheet

- Online Ordering

- Downloads

- Recommended Options

- Delivery & Packaging

| Features |

|---|

High Response Frequency

Based on advanced motion control algorithms, the velocity loop bandwidth is up to 3.2kHz, faster instruction tracking and shorter positioning time.

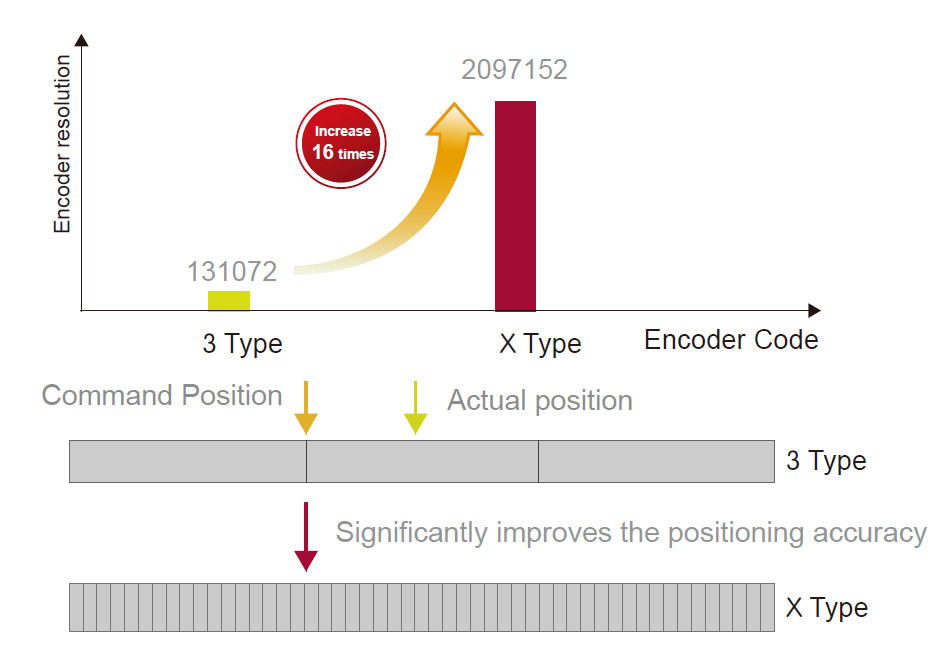

High Precision Positioning

The low cogging torque motor is equipped with high-resolution absolute encoder and built-in high-precision position control algorithm, which makes the servo system run more smoothly and with higher accuracy, and significantly improves the positioning accuracy of the equipment.21-bit Multi-turn Absolute Magnetic Encoder

◆ High resolution, up to 2,097,152 divisions per revolution

◆ Optional battery backup for 16-bit multi-turn

◆ Strong vibration resistance

◆ Resistant to dust and oil stains

◆ Anti condensation

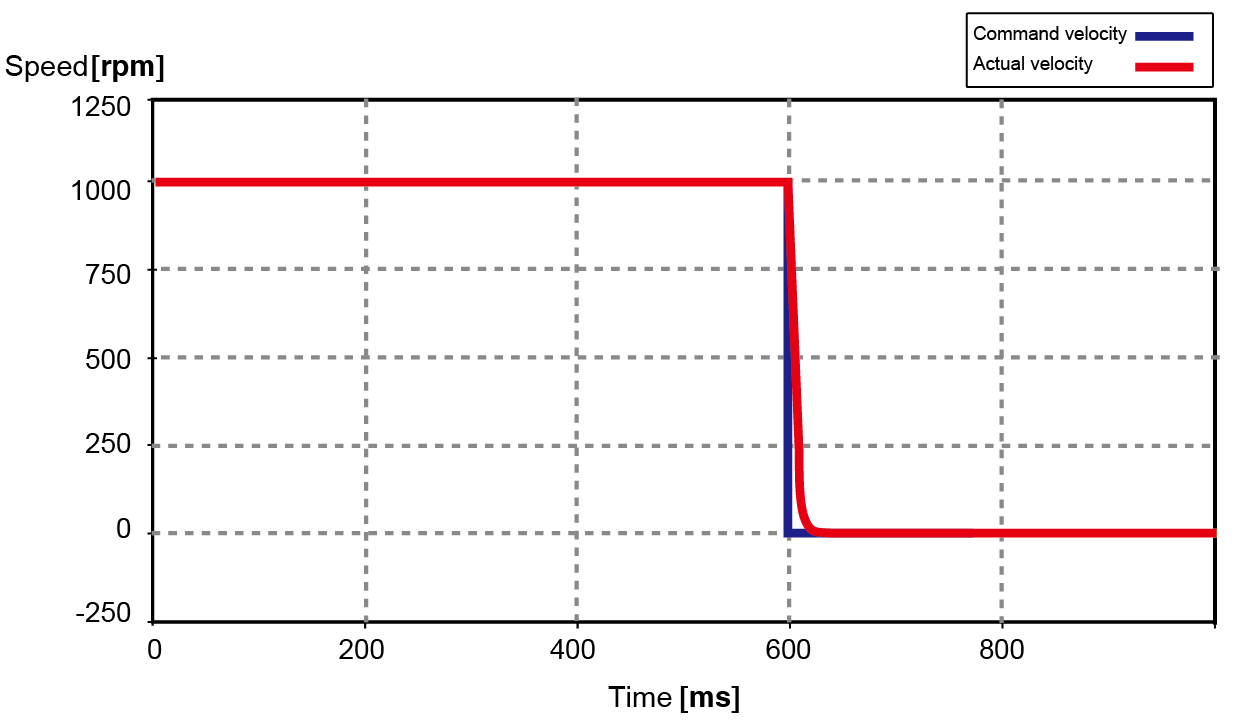

Super Tracking

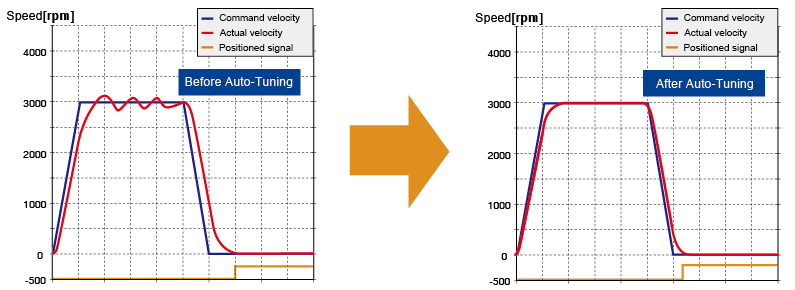

Using the super tracking control function, the motor not only runs at a constant speed, the following error is basically zero, and the following error is also close to zero during acceleration and deceleration, improving the trajectory accuracy of high-rigidity equipment.Auto-tuning

The real-time auto-tuning algorithm can automatically identify the load inertia (ratio), gain and vibration suppression parameters in real time.The auto-tuning function can greatly shorten your system tuning time, improve system responsiveness and equipment production efficiency.◆ No limitation towards any load type and drive control mode.

◆ High robustness for maximum control of servo system stability.

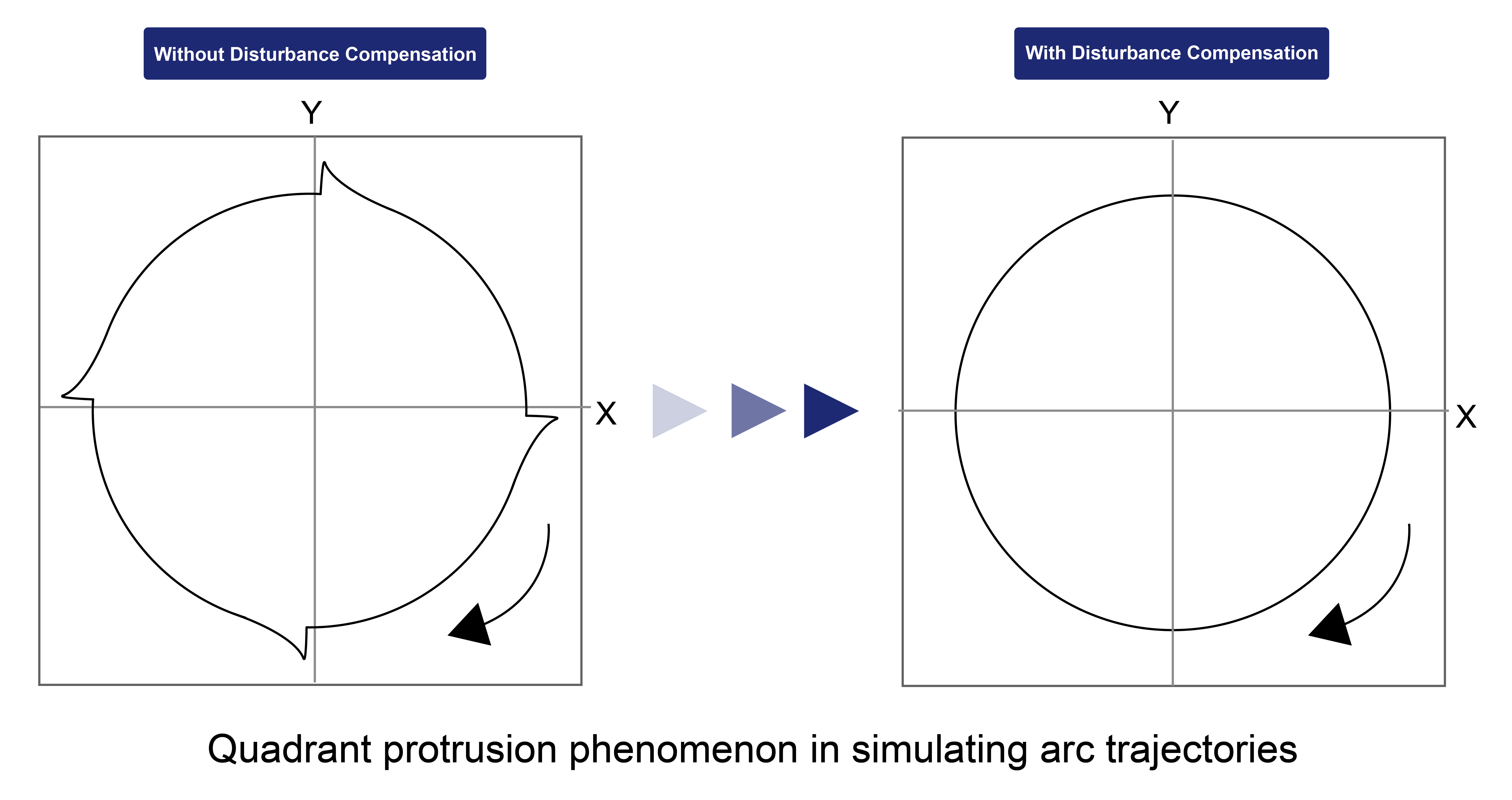

External Disturbance Compensation

The external disturbance compensation can effectively suppress the phenomenon of overquadrant bulge caused by the different friction of the mechanism and the influence of load change, and improve the tracking accuracy in multi-axis synchronous control.For example, the accuracy of arc trajectory in the interpolation control of XY mechanism can be improved.

Notch Filters

◆ 2 sets of automatically set notch filters can search and set resonance frequency automatically. ◆ 2 sets of manual notch filters for more adjust options.

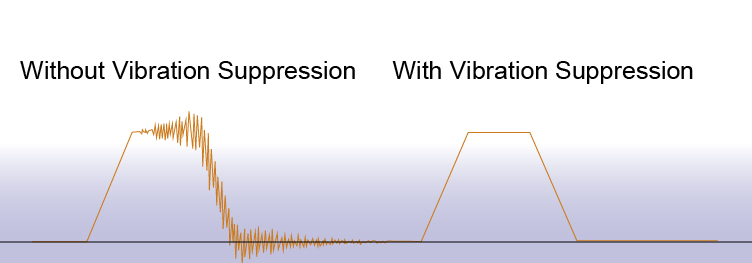

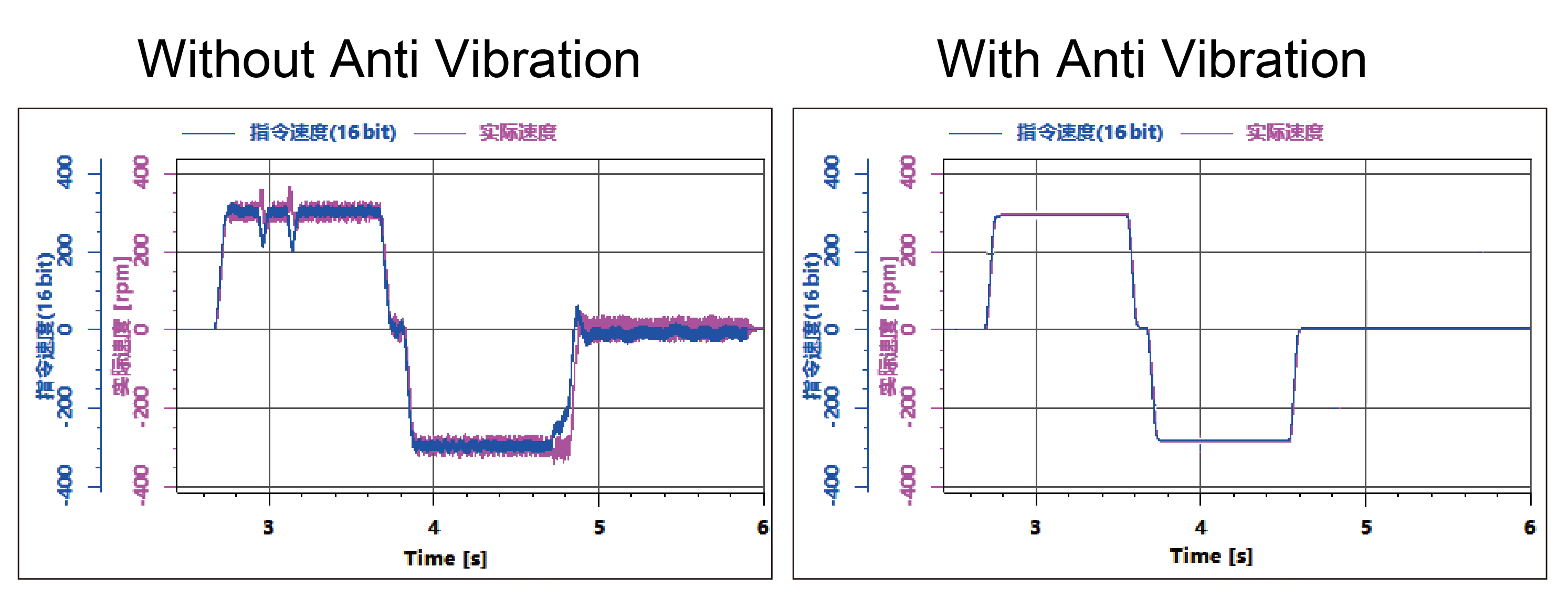

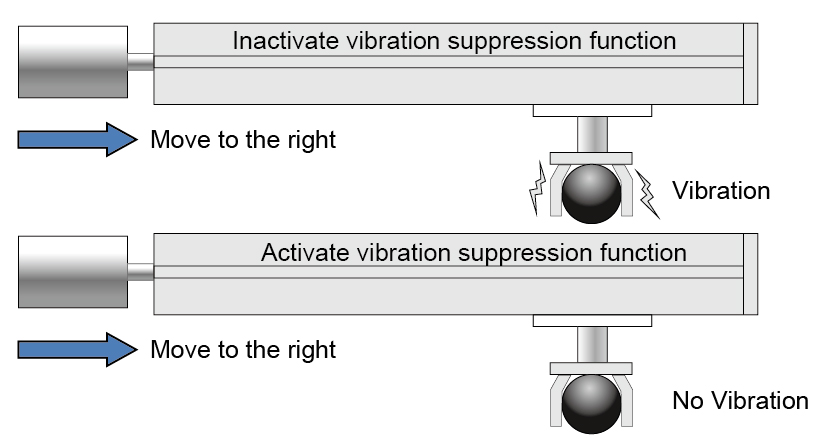

Novel Resonance Suppression The new resonance suppression function of the M54S series products can effectively suppress the low-frequency vibration caused by the resonance of 100 ~ 1000Hz. | Mechanical End Vibration Suppression Vibration at the end of the machine will lead to longer system settling time, resulting in decreased machine precision or production efficiency. M54S servo can suppress vibrations at the end of the machine, shortening tuning time, increasing the system precision and productivity. | |

|  |

Dynamic Braking

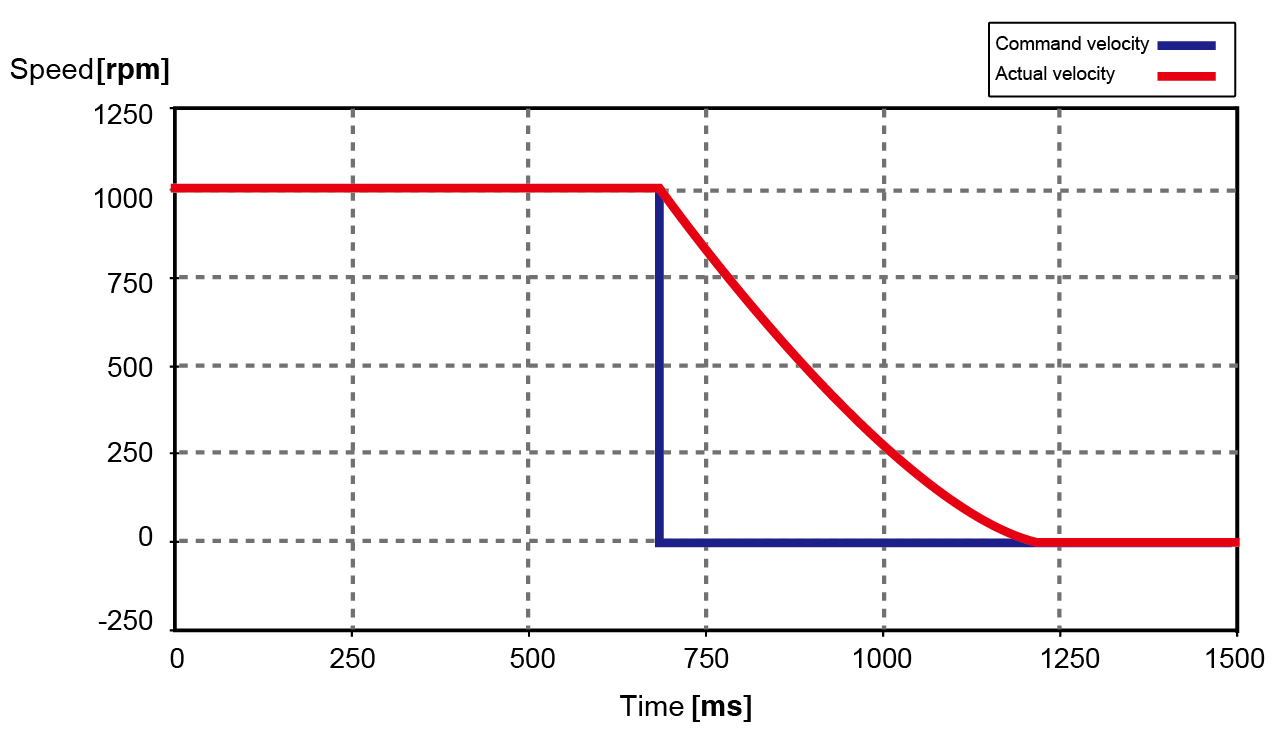

Dynamic braking can be used when a fault occurs at the motor or at the drive. Dynamic braking is implemented by short circuiting the U/V/W phases of the motor. This brings the motor to a stop at the highest deceleration rate and is meant to protect personnel and equipment. | Without Dynamic brake | With Dynamic brake | |

|  | |

| In this scenario, the drive exhibits a fault and is disabled. This results in the motor coming to an uncontrolled deceleration that is influenced purely by external factors such as the speed of the motor before fault, inertia of the system and the friction present in the system. | In this scenario, the drive exhibits a fault and the is disabled. The phases (U/V/W) of the servo motor are shorted and the current generated by the back EMF of the motor windings is used to stop the motor. This greatly reduces deceleration time and protects personnel as well as equipment. |

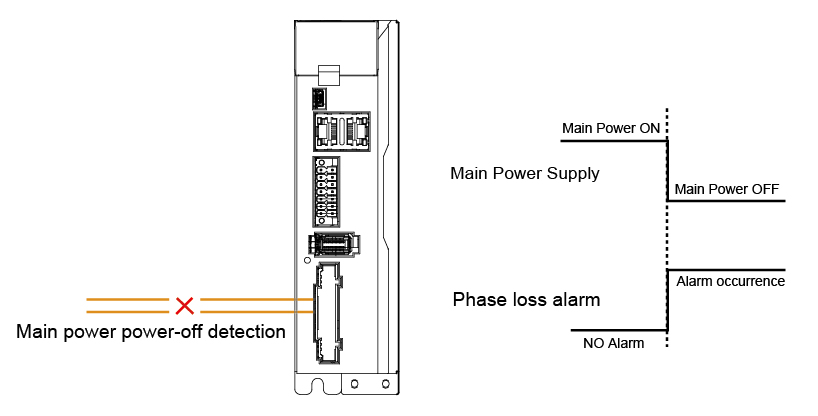

Built-in Regenerative Absorbing Resistor 750W and 1000W drives have built-in regenerative absorbing resistor, it can consume the regenerative energy generated when the motor and load decelerate rapidly, make sure the servo system can stop quickly and operate reliably. No additional regen resistor is required for most applications. | Main Power Power-off & Phase Loss Detection The M54S servo drives monitor main power and motor phase connections. Should either of these be lost, a fault will occur. This serves as an added protection measure against damage that might result from these issues. | |

|  |

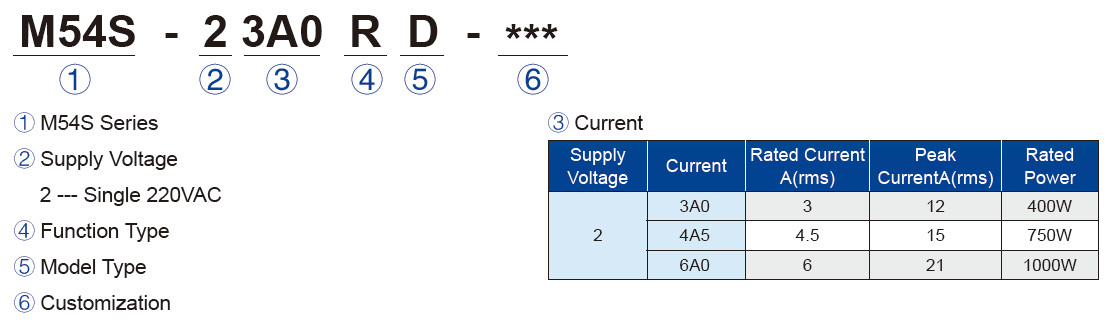

| Drive Part Numbering |

|---|

■ Drive Specification -R:RS-485 Type

| Input Power | M54S-23A0RD M54S-24A5RD M54S-26A0RD | Main Circuit | Single, AC200 ~ 240V ±10%,50/60Hz |

|---|---|---|---|

| Control Circuit | Powered by main circuit | ||

| Withstand Voltage | Primary to earth: withstand 1500 VAC, 1 min, (Leakage current: 20 mA) [220V Input] | ||

| Environment | Temperature | Ambient temperature: 0°C ~ 55°C (If the ambient temperature of servo drive is higher than 45°C, please install the drive in a well-ventilated location) Storage temperature: -20°C ~ 65°C | |

| Humidity | Both operating and storage : 10 ~ 85%RH or less | ||

| Altitude | Derating is not required for altitudes not higher than 1000m Derating 1% for every additional 100m for altitudes between 1000m and 2000m | ||

| Vibration | 9.8m/s2 or less, 10 - 60Hz (Do not use continuously at resonance frequency) | ||

| Motor Encoder Feedback | 21-bit Multi-turn Absolute Magnetic Encoder | ||

| I/O | Digital Signal | Input | 10 Configurable optically isolate digital general inputs, 24VDC, 20mA |

| Output | 6 Configurable optically isolate digital general outputs, Max. 30VDC, 100mA | ||

| Analog Signal | Input | 2 Analog inputs, -10 ~ +10V, 12bit | |

| Pulse Signal | Input | ● Optocoupler input: 5 ~ 24V, minimum pulse width 1μs, max. pulse frequency 500KHz ● Line Receiver input: 5V differential signal, minimum pulse width 0.125μs, max. pulse frequency 4MHz | |

| Output | ● Line Driver output: Encoder A、B、Z feedback output ● Open collector output: Encoder Z phase | ||

| Comm Port | USB | Connection with PC for configuration | |

| RS-485 | Modbus/RTU Communication protocol | ||

| Front Panel | 5 keys(MODE, RIGHT, UP, DOWN, SET) 5 - digital LED Display | ||

| Regeneration Resistor | 750W Built-in regenerative resistor (All models can be equipped with external absorption resistors) | ||

| Control Mode | 1. Pulse Position Mode 2. Analog Velocity Mode 3. Analog Torque Mode 4. Internal Position Mode 5. Internal Torque Mode 6. Internal Velocity Mode 7. Command Torque Mode Each control mode can be switched by digital input | ||

| Control Input Signal | Servo-ON, Alarm Reset, CW/CCW Limit, Control Mode Select, Gain Select, Clear Position Error, Zero Speed Clamp, Command and Velocity input Direction control, Command and Torque input Direction control, Emergency Stop, Homing Switch, Torque Limit, Speed Limit, Pulse Inhibit, Multi-velocity Switch, Start Q Program, General Purpose Input | ||

| Control Output Signal | Warning Output, Fault Output, Servo Ready, Velocity Reached, Torque Reached, Position Reached, Servo-on Status, Brake Release, Dynamic Position Error Following, Positioning Complete, Zero Speed Detected, Velocity Coincidence, Torque Coincidence, Velocity limit, Torque limit, Homing Finished, Soft Limit CW/CCW, General Purpose Output | ||

| Protection | Over Current, Over Voltage,Under Voltage, Over Temperature, Bad Encoder Feedback, Over Load, Over Speed, Positon Error, STO, CW/CCW Limit, Full Closed-loop Hybrid Deviation Fault, Communication exception | ||

| Dynamic Brake | Built in | ||

| STO*1 | Built in | ||

| Weight | M54S-23A0RD:1.0Kg M54S-24A5RD:1.3Kg M54S-26A0RD:1.5Kg | ||

Note: *1 Reserve STO interface. If you need this function, please contact sales personnel.

■ Drive Specification –EC: EtherCAT Type -C: CANopen Type

| Input Power | M54S-23A0 ■ N M54S-24A5 ■ N M54S-26A0 ■ N | Main Circuit | Single, AC200 ~ 240V ±10%,50/60Hz |

|---|---|---|---|

| Control Circuit | Powered by main circuit | ||

| Withstand Voltage | Primary to earth: withstand 1500 VAC, 1 min, (Leakage current: 20 mA) [220V Input] | ||

| Environment | Temperature | Ambient temperature: 0°C ~ 55°C (If the ambient temperature of servo drive is higher than 45°C, please install the drive in a well-ventilated location) Storage temperature: -20°C ~ 65°C | |

| Humidity | Both operating and storage : 10 ~ 85%RH or less | ||

| Altitude | Derating is not required for altitudes not higher than 1000m Derating 1% for every additional 100m for altitudes between 1000m and 2000m | ||

| Vibration | 9.8m/s2 or less, 10 ~ 60Hz (Do not use continuously at resonance frequency) | ||

| Motor Encoder Feedback | 21-bit Multi-turn Absolute Magnetic Encoder | ||

| I/O | Digital Signal | Input | 6 Configurable optically isolate digital general inputs, 24VDC, 20mA |

| Output | 3 Configurable optically isolate digital general outputs, Max. 30VDC, 100mA | ||

| Analog Signal | Input | 1 Analog input, -10 ~ +10V, 12bit | |

| Comm Port | USB | Connection with PC for configuration | |

| EtherCAT | -EC Control Function Type: EtherCAT communication | ||

| CANopen | -C Control Function Type: CANopen communication | ||

| Front Panel | 5 keys(MODE, RIGHT, UP, DOWN, SET) 5 - digital LED Display | ||

| Regeneration Resistor | 750W Built-in regenerative resistor (All models can be equipped with external absorption resistors) | ||

| Control Mode | -EC Control Function Type: CoE(Complies with CiA402 standard), support PP, PV, TQ, CSP, CSV, CST and HM mode, Q programs that are pre-stored in the drive can also be started by command -C Control Function Type: Complies with CiA402 standard, support PP, PV, TQ and HM mode, Q programs that are pre-stored in the drive can also be started by command | ||

| Control Input Signal | Alarm Reset, CW/CCW Limit, Gain Select, Zero Speed Clamp, Emergency Stop, CW/CCW Torque Limit, Speed Limit, General Purpose Input | ||

| Control Output Signal | Warning Output, Fault Output, Servo Ready, Velocity Reached, Torque Reached, Position Reached, Servo-on Status, Brake Release, Dynamic Position Error Following, Positioning Complete, Zero Speed Detected, Velocity Coincidence, Torque Coincidence, Velocity limit, Torque limit, Homing Finished, Soft Limit CW/CCW, General Purpose Output | ||

| Protection | Over Current, Over Voltage,Under Voltage, Over Temperature, Bad Encoder Feedback, Over Load, Over Speed, Positon Error, STO, CW/CCW Limit, Communication exception | ||

| Dynamic Brake | Built in | ||

| STO*1 | Built in | ||

| Weight | M54S-23A0 ■ N: 1.0Kg M54S-24A5 ■ N:1.3Kg M54S-26A0 ■ N:1.5Kg | ||

Note: *1 Reserve STO interface. If you need this function, please contact sales personnel. ■:Control Function Type

■ Safety Certification

| - | - | Drive | Motor |

|---|---|---|---|

| Europe | EMC | EN 61800-3 | EN 60034-1 |

| EN 61000-6-2 | |||

| EN 61000-6-4 | |||

| LVD | EN 61800-5-1 | EN 60034-1 | |

| EN 60034-5 |

■ Motor General Specifications

| Insulation class | Class F (155℃ ) | Ambient temperature | Working temperature: 0℃ ~ 40℃ Storage temperature: -20℃ ~ 60℃ |

|---|---|---|---|

| Protection level | IP67(Except transfixion part of shaft) | Humidity | Storage and usage: 20 ~ 85%RH ( no condensation ) |

| Installation conditions | Indoor installation, avoiding direct sunlight, corrosive and flammable gas | Altitude | Derating is not required for altitudes not higher than 1000m Derating 1% for every additional 100m for altitudes between 1000m and 2000m |

| Vibration | Under 49m/s2, 10 ~ 60Hz(Do not use continuously at resonance frequency ) |

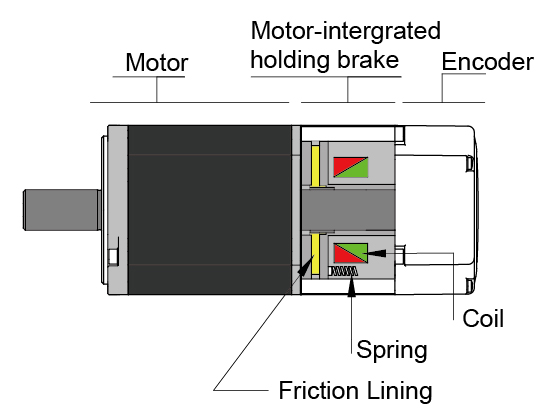

■ Brake Specifications

Motor brake is used to prevent motor from rotating by power off the servo system. The most common way of use is in vertical application, when the motor is disabled or powered off, in order to prevent the displacement of the mechanical mechanism driven by the motor due to gravity and other reasons, the servo motor with brake needs to be used.

When the brake is powered on, the armature is retracted, the brake pad is released, and the motor can operate normally. When the brake is powered off, the armature is released, the brake pad is locked, and the motor can't rotate.

When the brake is powered on, the armature is retracted, the brake pad is released, and the motor can operate normally. When the brake is powered off, the armature is released, the brake pad is locked, and the motor can't rotate.

| Frame | 40mm | 60mm | 80mm | 100mm | 130mm |  |

|---|---|---|---|---|---|---|

| Static Friction Torque N·m | 0.32 | 1.5 | 3.2 | 8.0 | 18.5 | |

| Rated Voltage VDC | 24 | |||||

| Power Waste(W 20℃) | 6.3 | 7.2 | 9.6 | 14.4 | 24.3 | |

| Current A | 0.26 | 0.3 | 0.4 | 0.6 | 1.05 | |

| Braking Time | (Standard air gap,at 20℃) <70ms | |||||

| Release Time | <25ms | |||||

| Release Voltage | 18.5VDC max.(at 20℃) | |||||

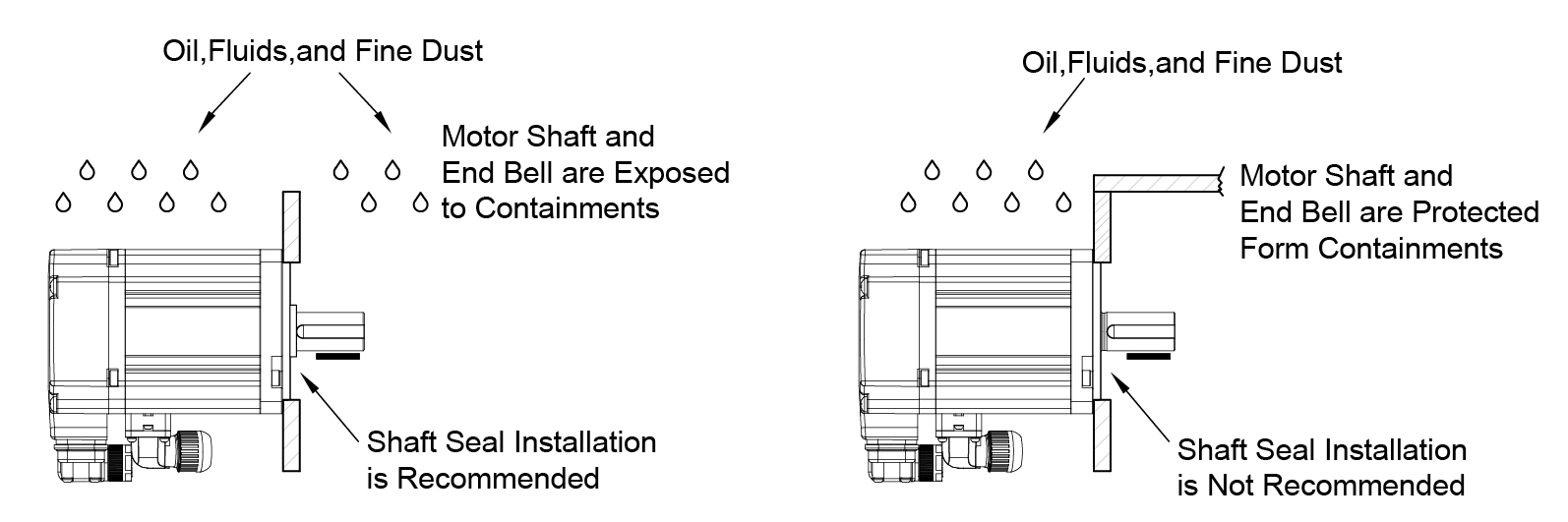

■ Shaft Seal

Industrial oil seals can block contaminants (oils, impurities) to extend the life of the motor. The oil seal will produce a certain resistance to the motor shaft, about 10% torque will be lost.

| Compare | Item | Price (USD) |

|---|---|---|

|

|

M54S-23A0RD | |

|

|

M54S-24A5RD | |

|

|

M54S-26A0RD | |

|

|

M54S-23A0ECN | |

|

|

M54S-24A5ECN | |

|

|

M54S-26A0ECN |

2D Drawings

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| M54S-23A0RD.PDF | 380 | ||

| M54S-24A5RD.PDF | 373 | ||

| M54S-23A0ECN.PDF | 388 | ||

| M54S-23A0RD.DWG | DWG | 712 | |

| M54S-23A0ECN.DWG | DWG | 632 | |

| M54S-24A5RD.DWG | DWG | 583 | |

| M54S-24A5ECN.PDF | 382 | ||

| M54S-26A0ECN.pdf | 385 | ||

| M54S-26A0RD.pdf | 348 | ||

| M54S-26A0RD.DWG | DWG | 311 | |

| M54S-24A5ECN.DWG | DWG | 628 | |

| M54S-26A0ECN.DWG | DWG | 545 |

3D Model

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| M54S-23A0RD.stp | STEP | 18267 | |

| M54S-24A5RD.stp | STEP | 17932 | |

| M54S-23A0ECN.stp | STEP | 21810 | |

| M54S-24A5ECN.stp | STEP | 12206 | |

| M54S-26A0RD.stp | STEP | 21212 | |

| M54S-26A0ECN.stp | STEP | 12206 |

Catalog

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| M54S Family Brochure_EN-20250220-A1.pdf | 4170 |

Certification

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| ROHS declaration-2024-A0.pdf | 522 | ||

| M56S&M54S Series Drive CE Certification-EMC.pdf | 1659 | ||

| M5&M3DV Series Servo Drive CE Certification-LVD.pdf | 1374 | ||

| M5 Series Servo Drive SEMI F47 Certification.pdf | 718 |

Software

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| Luna Setup 4.0.24.1130.zip | ZIP | 30628 | |

| AMA Servo EtherCAT v3.4.16.zip | XML | 138 |

Filter By Product Type

All ProductsUSB Cable

Extended I/O cable

Communication Daisy Chain Cable

Servo Motors

Delivery & Packaging

Ensure your ordered products are always safely packaged from easy click to fast delivery to your handsProfessional Product Label

Considering all possible harsh application environments, MOONS' specially designed labels for each product, which pass water-resistance test, durability rub test, high temperature resistance and corrosion resistance tests.Besides, our product labels are attached with QR code linking to product details, which is convenient for clients to view the detail product page with their mobile phones.

Note: This label design is suitable for products of stepper motor.

(Professional packing box and unique appearance design)

(Single item packed with EPE)

(Multi-products packed with another box)

Safely Packaging

In order to ensure your shipments withstand the long trip and arrive safely and intact, MOONS' specially designed Individual package to pass the drop test with its stable structure.Besides,the package is made from recyclable materials, providing you with professional safety delivery.

Whether just single item or multi-products the clients buy, all products are packed twice to avoid the damage further.

Shipping Visualization

For each case, products are carefully packed by experienced warehouse staff and the key processes are recorded by photos, which are then posted on our website, so that clients could clearly know the packing process and logistics status after placing order.

(Product in the box)

(Add the invoice)

(Label the commodity)

(The logistics waybill attached)

Fast Delivery

Fast Cross-Border DeliveryMOONS' chooses DHL as our main international express shipping partner. As the world's leading logistics specialist, DHL provides our customers with fast and professional inter- national door-to-door delivery service.

Estimated Delivery Time: e.g. China-USA major cities 3 business days.

Professional

Warehouse Management

Free Exchange

Free Exchange