1、Summary

The hollow part of a hollow shaft motor (also known as a hollow shaft motor) can be fitted with optical components such as lenses and prisms so that it can be used as a high-precision rotating optical device. In addition, it can be used to connect gearboxes and other mechanisms. In addition to optimizing the mechanical design of the hollow shaft motor, the hollow shaft motor saves design space, reduces design time, and facilitates maintenance. Hollow shaft motors are widely used in semiconductor equipment, optical equipment, and motion platforms. Its advantages include its small size, lightweight, low noise, multi-purpose capability, and ease of use. With its unique magnetic circuit design, precise machining, and precise assembly technology, MOONS' has broken through the limitations of traditional hollow shaft stepper motors, enabling it to maintain high rotation speed torque and smooth operation despite having the characteristics of a large hollow shaft inner hole.

Based on the technologies described above, MOONS' will develop five series of hollow shaft stepping motors. 2、Output shaft type

Due to the hollow nature of the rotating shaft of hollow shaft motors, the shaft can be directly used in a variety of applications. As a result, hollow shaft motors have a different type of connection than traditional motors. It is important to note that the main mechanical interfaces of hollow shaft motors are the bare shaft, the bayonet hollow, and the flange connection, which is divided into horizontal and vertical flanges. Hollow shaft motors are characterized by four types of shaft output:

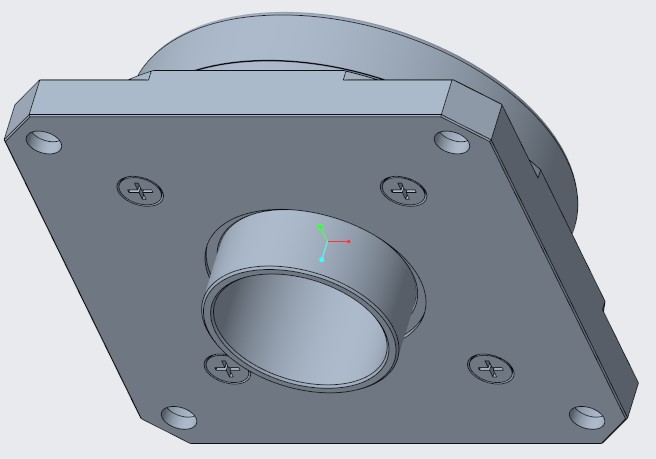

1) Bare shaft

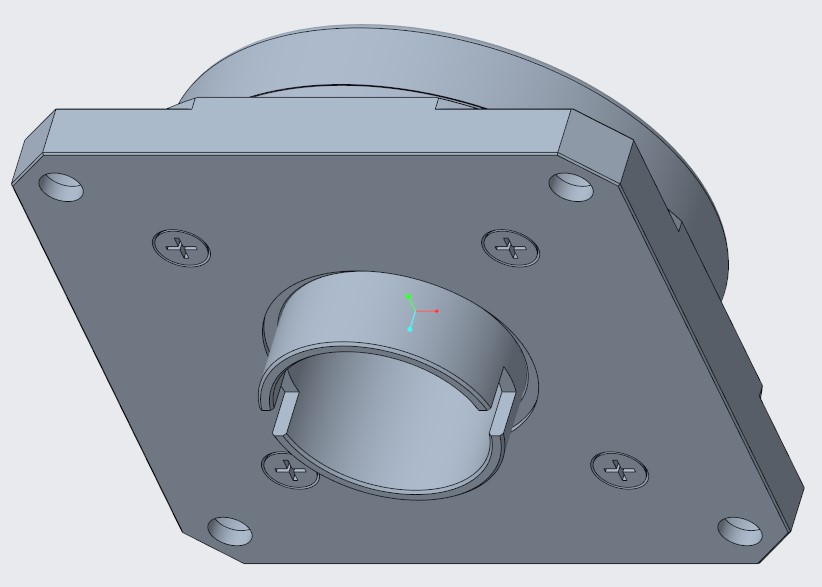

2) Bayonet hollow: Hollow bayonet direct connection.

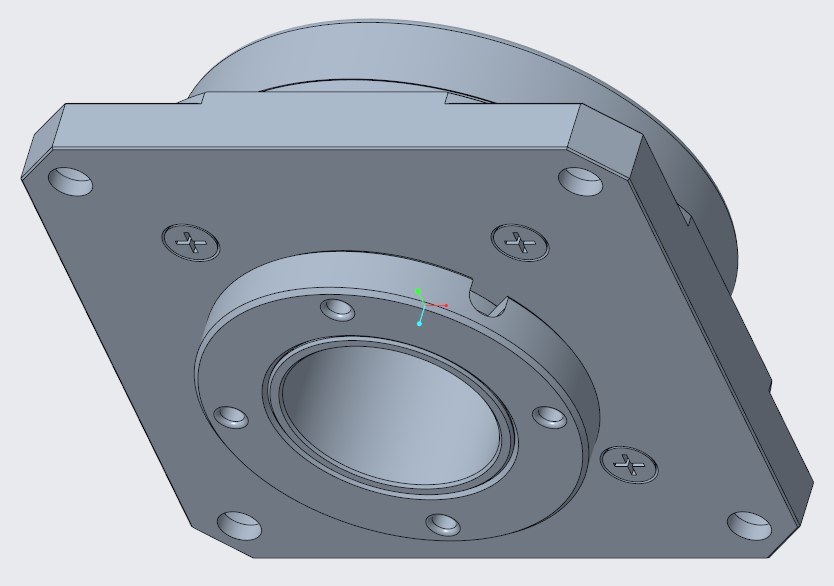

3) Vertical flange: Axial threaded hole.

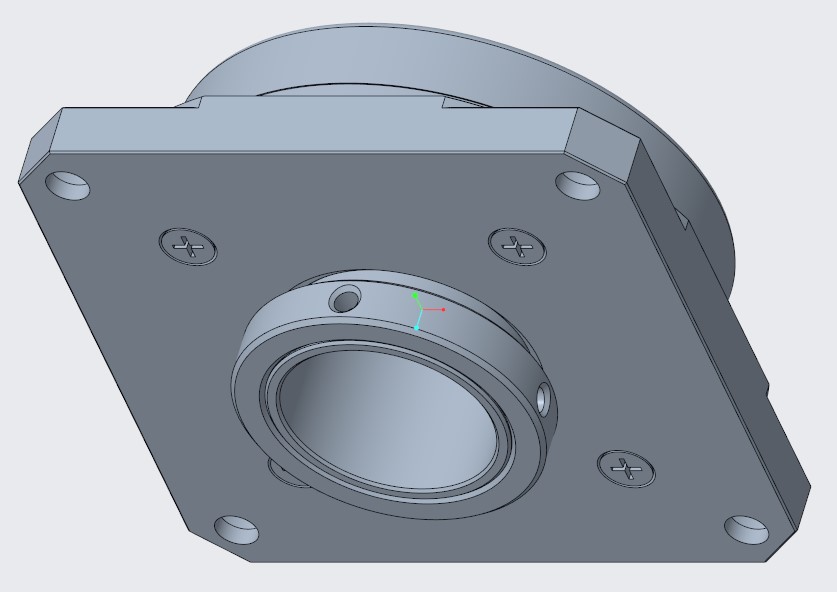

4) Horizontal flange: Radial threaded hole.

1) Bare shaft

2) Bayonet hollow

3)Vertical flange

4) Horizontal flange

3、Application examples

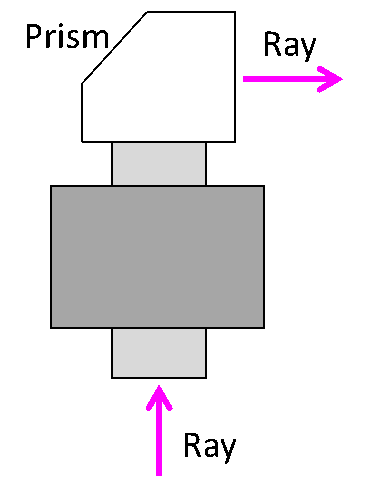

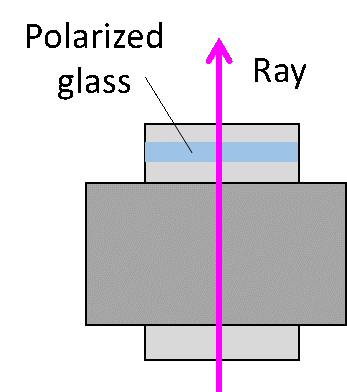

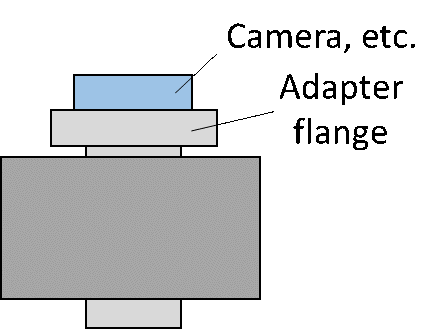

In hollow shaft stepping motors, optical elements such as prisms, polarizers, or cameras can be mounted on the inner or outer shaft. Thus, complex installation and debugging work can be eliminated and a rotatable high-precision optical device can be manufactured directly.

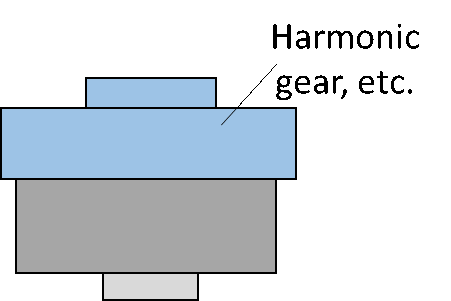

Hollow shafts may also be associated with harmonic gearboxes, which can provide high torque as well as high precision.

Hollow shafts may also be associated with harmonic gearboxes, which can provide high torque as well as high precision.

4、Specifications

We can customize the following specifications, electrical parameters, output shaft type, etc. Table 1 Parameters of hollow shaft stepping motors

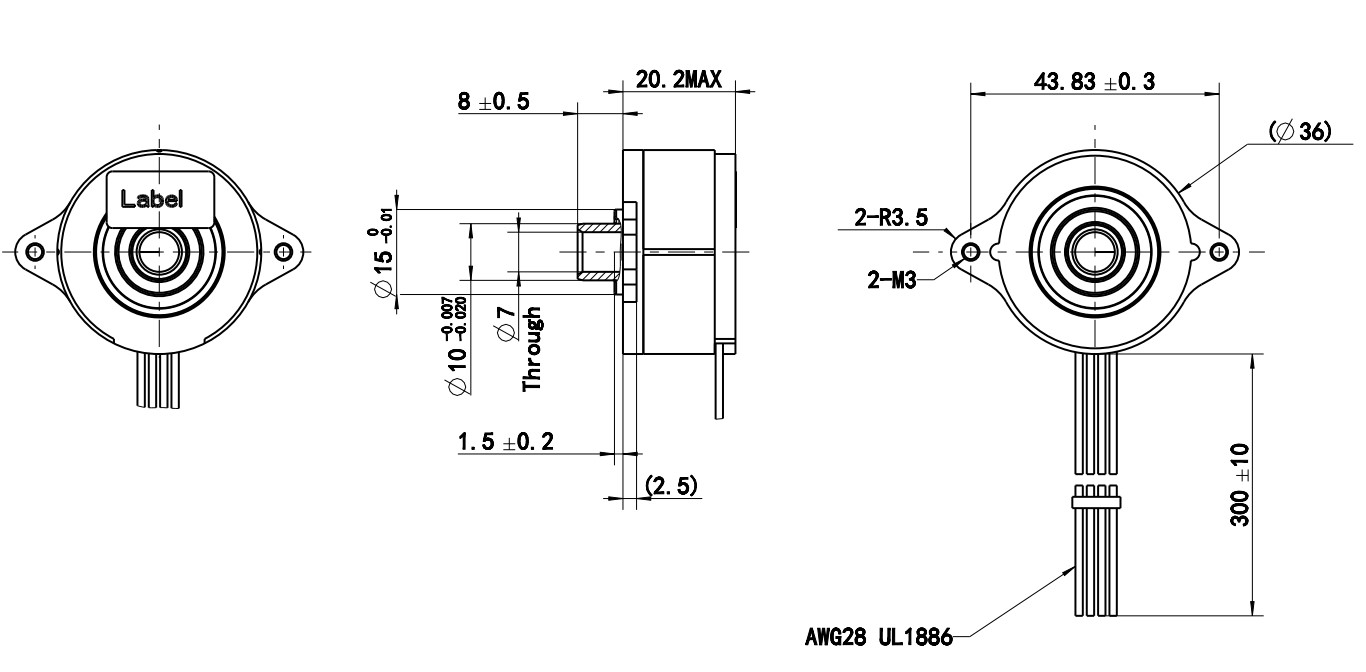

HS/VHS14HRA Outline Drawing

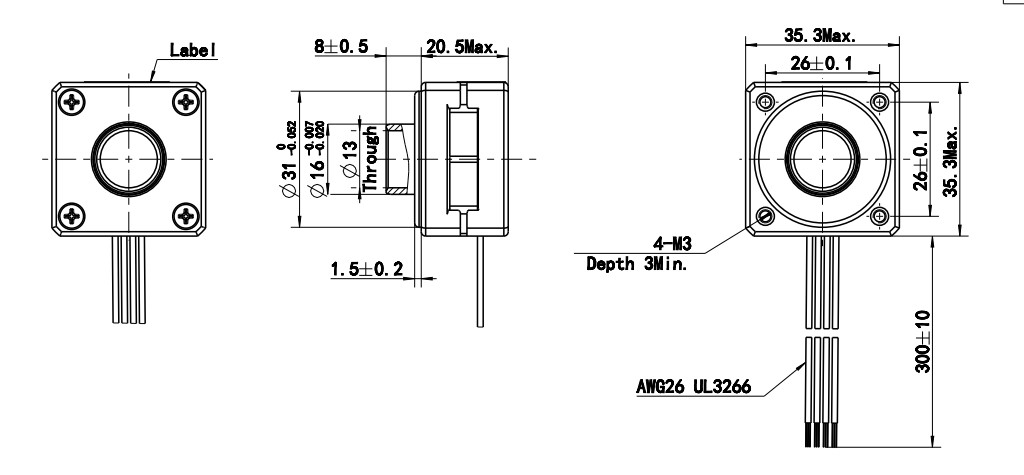

HS/VHS14HS Outline Drawing

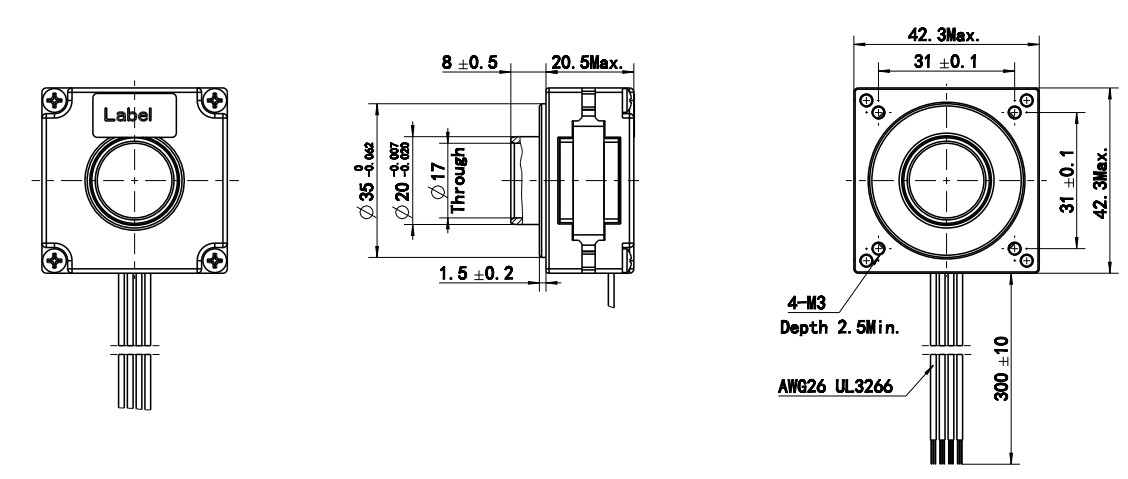

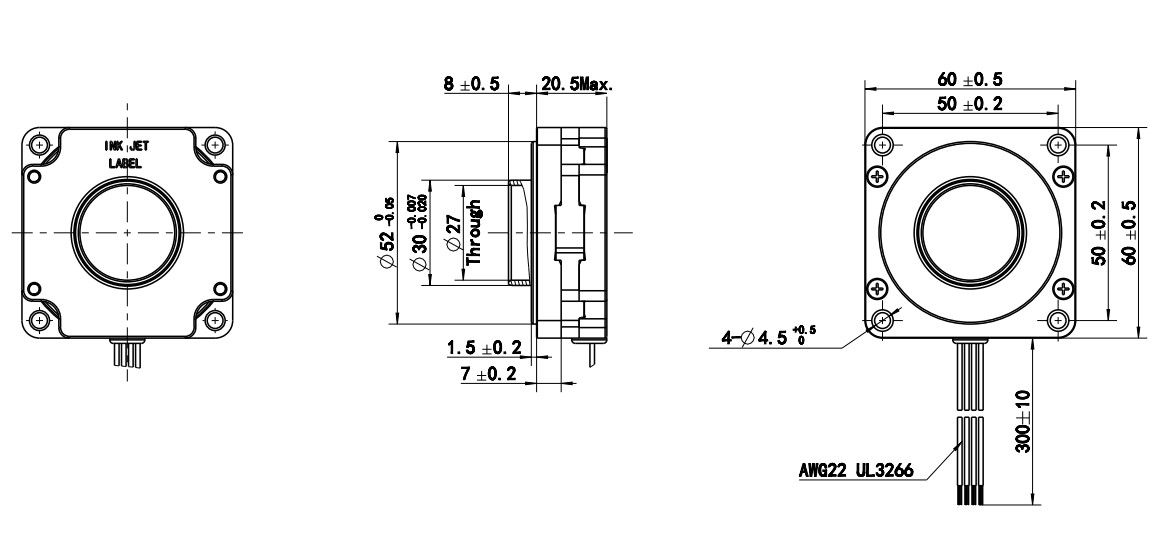

HS/VHS17HX Outline Drawing

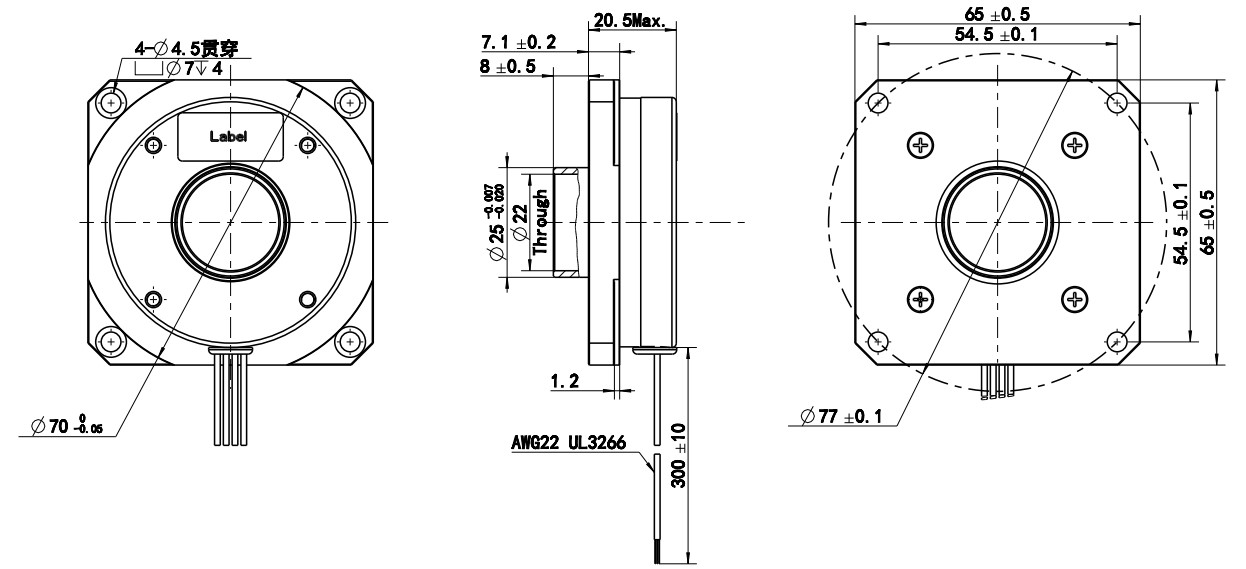

HS/VHS23HM Outline Drawing

HS/VHS24HS Outline Drawing