Field Bus Control Option

In present time, fieldbus control system is hot spot in the field of automation control technology, which is being paid more and more attention by users and automatic equipment manufacturers.

MOONS' drives and integrated motor products support EtherCAT control, CANopen over EtherCAT (CoE) protocol, EtherNET/IP protocol, CANopen protocal (Based on CANbus) and Modbus/RTU Protocol as well. With MOONS' developed SCL serial communication language, and stand-alone Q programmer control mode. It offers great efficiency, reliable, cost effective methods for field bus motion control solutions.

MOONS' Support CAN application protocol over EtherCAT (CoE)

MOONS' Support CAN application protocol over EtherCAT (CoE)

MOONS' drives support for CANopen over EtherCAT (CoE) control to allow them to be integrated into new and existing EtherCAT networks. Supported CiA 402 operating modes include Profile Position, Profile Velocity, Profile Torque, Cyclic Synchronous Position, and Cyclic Synchronous Velocity.

MOONS' Support for Beckhoff and Trio

Currently we provide connection guides for Beckhoff Automation's TwinCAT 2 software and Trio Motion's Motion Perfect software. Users of these software and controller solutions can utilize the EtherCAT Connection Guides to more rapidly and easily incorporate SS-EC drives and motors onto their networks. If you want to integrate StepSERVO drives and motors into your EtherCAT network as fast as possible, these EtherCAT Connection Guides will help you do just that. EtherCAT Operating PrincipleThe unique way that EtherCAT works makes it the clear "engineer's choice."

Resource: from Wikipedia Why Use EtherCAT®?

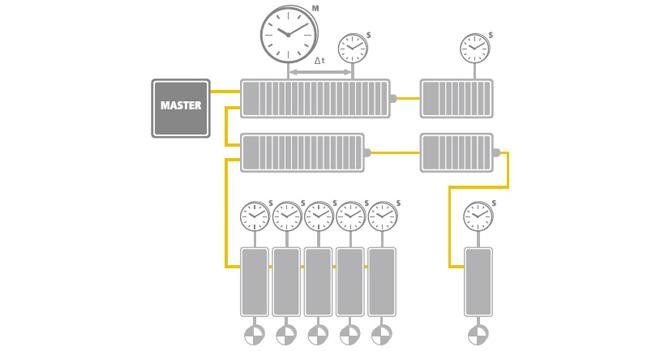

1. Exceptional performance EtherCAT is by and large the fastest Industrial Ethernet technology, but it also synchronizes with nanosecond accuracy. This is a huge benefit for all applications in which the target system is controlled or measured via the bus system. The rapid reaction times work to reduce the wait times during the transitions between process steps, which significantly improve application efficiency. EtherCAT's performance leads to improved accuracy, greater throughput, and thus to lowered costs. Completely hardware-based synchronization with compensation for propagation delays.2. Flexible topologyIn conventional Industrial Ethernet systems, there are limitations on how many switches and hubs can be cascaded, which thus limits the overall network topology. Since EtherCAT doesn't need hubs or switches, there are no such limitations. In short, EtherCAT is virtually limitless when it comes to network topology. Line, tree, star topologies and any combinations thereof are possible with a nearly unlimited number of nodes. Thanks to automatic link detection, nodes and network segments can be disconnected during operation and then reconnected. This makes switching out devices during machine operation possible.

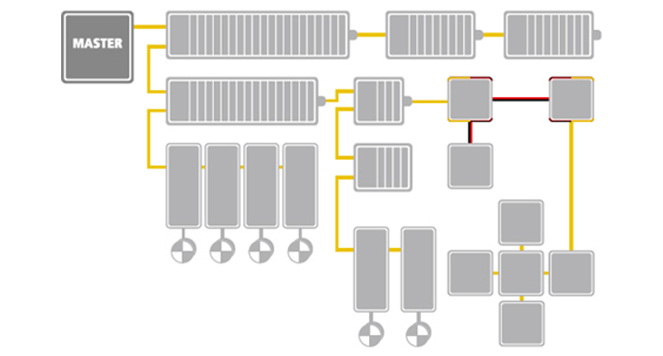

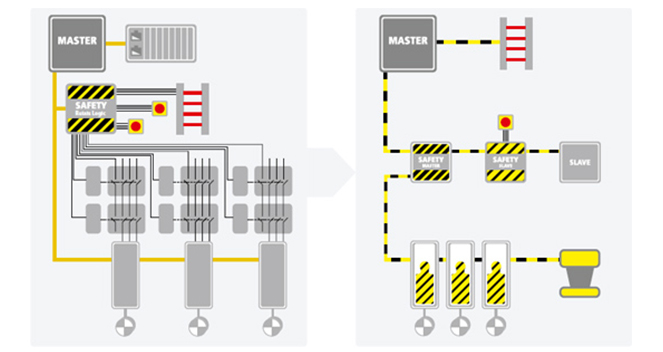

Completely hardware-based synchronization with compensation for propagation delays.2. Flexible topologyIn conventional Industrial Ethernet systems, there are limitations on how many switches and hubs can be cascaded, which thus limits the overall network topology. Since EtherCAT doesn't need hubs or switches, there are no such limitations. In short, EtherCAT is virtually limitless when it comes to network topology. Line, tree, star topologies and any combinations thereof are possible with a nearly unlimited number of nodes. Thanks to automatic link detection, nodes and network segments can be disconnected during operation and then reconnected. This makes switching out devices during machine operation possible. Flexible topology - line, tree or star3. It's simple and robustConfiguration, diagnostics, and maintenance are all factors that contribute to system costs. The Ethernet fieldbus makes all of these tasks significantly easier: EtherCAT can be set to automatically assign addresses, which eliminates the need for manual configuration. A low bus load and peer-to-peer physics improve electromagnetic noise immunity. The network reliably detects potential disturbances down to their exact location, which drastically reduces the time needed for troubleshooting. During startup, the network compares the planned and actual layouts to detect any discrepancies. EtherCAT performance also helps during system configuration by eliminating the need for network tuning. Thanks to the large bandwidth, there is capacity to transmit additional TCP/IP together with the control data. However, since EtherCAT itself isn't based on TCP/IP, there is no need to administer MAC-addresses or IP-addresses or to have IT experts configure switches and routers.4. Integrated SafetyFunctional Safety over EtherCAT (FSoE) is proven in use through TÜV certified devices that have been on the market since 2005. The protocol fulfills the requirements for SIL 3 systems and is suitable for both centralized and decentralized control systems. Thanks to the Black-Channel approach and the particularly lean Safety-Container, FSoE can also be used in other bus systems. This integrated approach and the lean protocol help keep system costs down. Additionally, a non-safety critical controller can also receive and process safety data.

Flexible topology - line, tree or star3. It's simple and robustConfiguration, diagnostics, and maintenance are all factors that contribute to system costs. The Ethernet fieldbus makes all of these tasks significantly easier: EtherCAT can be set to automatically assign addresses, which eliminates the need for manual configuration. A low bus load and peer-to-peer physics improve electromagnetic noise immunity. The network reliably detects potential disturbances down to their exact location, which drastically reduces the time needed for troubleshooting. During startup, the network compares the planned and actual layouts to detect any discrepancies. EtherCAT performance also helps during system configuration by eliminating the need for network tuning. Thanks to the large bandwidth, there is capacity to transmit additional TCP/IP together with the control data. However, since EtherCAT itself isn't based on TCP/IP, there is no need to administer MAC-addresses or IP-addresses or to have IT experts configure switches and routers.4. Integrated SafetyFunctional Safety over EtherCAT (FSoE) is proven in use through TÜV certified devices that have been on the market since 2005. The protocol fulfills the requirements for SIL 3 systems and is suitable for both centralized and decentralized control systems. Thanks to the Black-Channel approach and the particularly lean Safety-Container, FSoE can also be used in other bus systems. This integrated approach and the lean protocol help keep system costs down. Additionally, a non-safety critical controller can also receive and process safety data.

EtherCAT utilizes the protocol Safety over EtherCAT allows:

--A single communication system for both control and safety data

--The ability to flexibly modify and expand the safety system architecture

--Pre-certified solutions to simplify safety applications

--Powerful diagnostic capabilities for safety functions

--Seamless integration of the safety design in the machine design

--The ability to use the same development tools for both standard and safety applications Safety over EtherCAT enables simpler and more flexible architectures than with relay logic5. AffordabilityEtherCAT delivers the features of Industrial Ethernet at a price similar or even below that of a classic fieldbus system. The only hardware required by the master device is an Ethernet port - no expensive interface cards or co-processors are necessary. EtherCAT slave controllers are available from various manufacturers in different formats: as an ASIC, based on FPGA, or also as an option for standard microprocessor series. Since these inexpensive controllers shoulder all the time-critical tasks, EtherCAT itself doesn't place any performance requirements on the CPU of slave devices, which keeps device costs down. Since EtherCAT doesn't require switches or other active infrastructure components, the costs for these components and their installation, configuration, and maintenance are also eliminated.

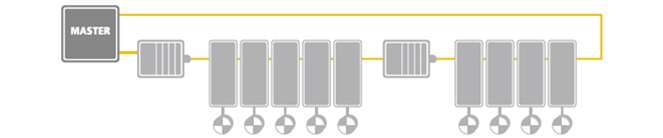

Safety over EtherCAT enables simpler and more flexible architectures than with relay logic5. AffordabilityEtherCAT delivers the features of Industrial Ethernet at a price similar or even below that of a classic fieldbus system. The only hardware required by the master device is an Ethernet port - no expensive interface cards or co-processors are necessary. EtherCAT slave controllers are available from various manufacturers in different formats: as an ASIC, based on FPGA, or also as an option for standard microprocessor series. Since these inexpensive controllers shoulder all the time-critical tasks, EtherCAT itself doesn't place any performance requirements on the CPU of slave devices, which keeps device costs down. Since EtherCAT doesn't require switches or other active infrastructure components, the costs for these components and their installation, configuration, and maintenance are also eliminated. Inexpensive cable redundancy with standard EtherCAT slave devicesReference:

Inexpensive cable redundancy with standard EtherCAT slave devicesReference:

EtherCAT From Wikipedia

EtherCAT Technology Group

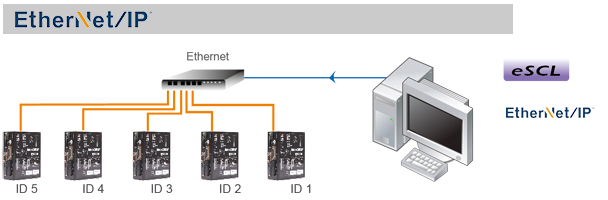

Note: EtherCAT® is a registered trademark of Beckhoff Automation GmbH.Manual: EtherCAT User Manual For STF, EtherCAT User Manual for SS-EC back to top  EtherNet/IP was introduced in 2001 and today is the most developed, proven and complete industrial Ether-net network solution available for manufacturing automation. EtherNet/IP is a member of a family of networks that implements the Common Industrial Protocol (CIP) at its upper layers. CIP encompasses a comprehensive suite of messages and services for a variety of manufacturing automation applications, including control, safety, syn-chronization, motion, configuration and information. As a truly media independent protocol that is supported by hundreds of vendors around the world, CIP provides users with a unified communication architecture throughout the manufacturing enterprise.

EtherNet/IP was introduced in 2001 and today is the most developed, proven and complete industrial Ether-net network solution available for manufacturing automation. EtherNet/IP is a member of a family of networks that implements the Common Industrial Protocol (CIP) at its upper layers. CIP encompasses a comprehensive suite of messages and services for a variety of manufacturing automation applications, including control, safety, syn-chronization, motion, configuration and information. As a truly media independent protocol that is supported by hundreds of vendors around the world, CIP provides users with a unified communication architecture throughout the manufacturing enterprise.

MOONS' has a wide range of products that supports Ethernet/IP protocol, including stepper series, step-servo series, and servo series products. Combine with MOONS' Q programmer control, it offers great range of control options, including various commands, and up to 130 data registers.Features:

• Real time motion control

• High Precision

• Easily repeatable

• High speed

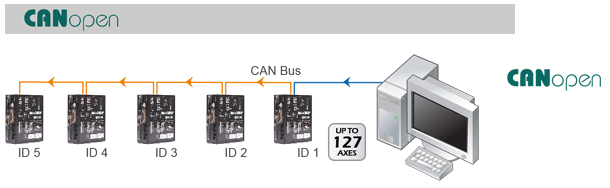

• Large number axes controlback to top  CANopen is a communication protocol and device profile specification for embedded systems used in automation. In terms of the OSI model, CANopen implements the layers above and including the network layer. The CANopen standard consists of an addressing scheme, several small communication protocols and an application layer defined by a device profile. The communication protocols have support for network management, device monitoring and communication between nodes, including a simple transport layer for message segmentation/desegmentation. The lower level protocol implementing the data link and physical layers is usually Controller Area Network (CAN) The basic CANopen device and communication profiles are given in the CiA 301 specification released by CAN in Automation.[1] Profiles for more specialized devices are built on top of this basic profile, and are specified in numerous other standards released by CAN in Automation, such as CiA 401[2] for I/O-modules and CiA 402[3] for motion control.Features:

CANopen is a communication protocol and device profile specification for embedded systems used in automation. In terms of the OSI model, CANopen implements the layers above and including the network layer. The CANopen standard consists of an addressing scheme, several small communication protocols and an application layer defined by a device profile. The communication protocols have support for network management, device monitoring and communication between nodes, including a simple transport layer for message segmentation/desegmentation. The lower level protocol implementing the data link and physical layers is usually Controller Area Network (CAN) The basic CANopen device and communication profiles are given in the CiA 301 specification released by CAN in Automation.[1] Profiles for more specialized devices are built on top of this basic profile, and are specified in numerous other standards released by CAN in Automation, such as CiA 401[2] for I/O-modules and CiA 402[3] for motion control.Features:

• High communication rate

• Communication error tolerance

• Up to 127 axes control

• Standard communication protocolManual: CANopen user manual

Software Download: CANopen Test Tool

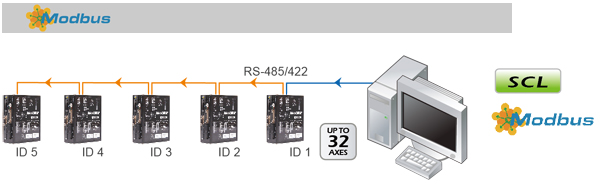

Motion Control Library: CANopen Libraryback to top  Modbus communication protocol is a kind of industrial field bus communication protocol, which is the application layer on the OSI 7packet transport protocol. It defines a device controller which can identify the frame structure and information. It is independent of the physical medium and can be used over various networks.

Modbus communication protocol is a kind of industrial field bus communication protocol, which is the application layer on the OSI 7packet transport protocol. It defines a device controller which can identify the frame structure and information. It is independent of the physical medium and can be used over various networks.

Since Modbus is a master/slave protocol, that means only one node is a master and the others is slave node .Each device intended to communicate using Modbus is given a unique address. In serial networks, only the node assigned as the Master may initiate a command.

A Modbus command contains the Modbus address of the device it is intended for. Only the intended device will act on the command, even though other devices might receive it (an exception is specific broadcast able commands sent to node 0 which are acted on but not acknowledged). All Modbus commands contain checksum information, to allow the recipient to detect transmission errors. The basic Modbus commands can instruct an RTU to change the value in one of its registers, control or read an I/O port, and command the device to send back one or more values contained in its registers.Features:

• RS485/422 communication

• Cost effective

• Maximum 32 axes control

• User friendlyManual: Modbus RTU Manual

Software Download: Modbus/RTU Library Setup 1.0.20.0818

Software Download: Modbus/TCP Library Setup 1.0.18.0929back to top  SCL or Serial Command Language was developed by MOONS' to give users a simple way to control a motor drive via serial port. This eliminates the need for separate motion controllers to supply control signals, like Pulse & Direction or +/-10V signals, to your step and servo motor drives. It also provides an easy way to interface to a variety of other industrial devices like PLCs and HMIs, which most often have standard or optional serial ports for communicating to other devices.

SCL or Serial Command Language was developed by MOONS' to give users a simple way to control a motor drive via serial port. This eliminates the need for separate motion controllers to supply control signals, like Pulse & Direction or +/-10V signals, to your step and servo motor drives. It also provides an easy way to interface to a variety of other industrial devices like PLCs and HMIs, which most often have standard or optional serial ports for communicating to other devices.

eSCL is developed based on MOONS' SCL command, it allows the SCL to transfer via Ethernet from the host control to the driver. There are two types of host commands available: buffered and immediate. Buffered commands are loaded into and executed out of the drive's volatile command buffer, also known as the queue. Immediate commands are not buffered: when received by the drive they are executed immediately. Manual: HOST COMMAND reference

Motion Control Library: SCL Library

Motion Control Library: eSCL Libraryback to top  The use of SCL commands with MOONS' dates back many years. A few years ago a new control platform was created that expanded the use of SCL commands and allowed users to create stored programs with SCL commands. These programs could be saved in a drive's non-volatile memory, and the drive could run these programs stand-alone, or without a permanent connection to the host. This expansion of SCL's capabilities was called Q, and since that time MOONS' has continued to expand the offering of drives with the Q motion controller built in. By combining the ability to run a sophisticated, single-axis motion control program stand-alone and the ability to communicate serially to a host device, Q drives offer a high level of flexibility and functionality to the machine designer and system integrator.Features:

The use of SCL commands with MOONS' dates back many years. A few years ago a new control platform was created that expanded the use of SCL commands and allowed users to create stored programs with SCL commands. These programs could be saved in a drive's non-volatile memory, and the drive could run these programs stand-alone, or without a permanent connection to the host. This expansion of SCL's capabilities was called Q, and since that time MOONS' has continued to expand the offering of drives with the Q motion controller built in. By combining the ability to run a sophisticated, single-axis motion control program stand-alone and the ability to communicate serially to a host device, Q drives offer a high level of flexibility and functionality to the machine designer and system integrator.Features:

• Single-Axis motion control

• Stand Alone

• Multi-task

• Conditional Processing

• Math Calculation

• Data register manipulation

• Up to 62 line of command in one segment, and Up to 12 segments in one program.Manual: HOST COMMAND reference

Software Download: Q programmerback to top